Lost foam-shell mold casting vibration and solidification method based on foam mold

A foamed plastic and shell casting technology, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of large grain size of lost foam shell castings, and achieve excellent internal quality, refined grain size, The effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Vibration Solidification of Lost Pattern Shell Mold Casting of AZ91D Magnesium Alloy

[0019] (1) Prepare the foam plastic pattern, soak the foam mold with paint, then sprinkle sand, repeat the above operation twice after drying, and form 2 layers of ceramic shells on the surface of the foam mold;

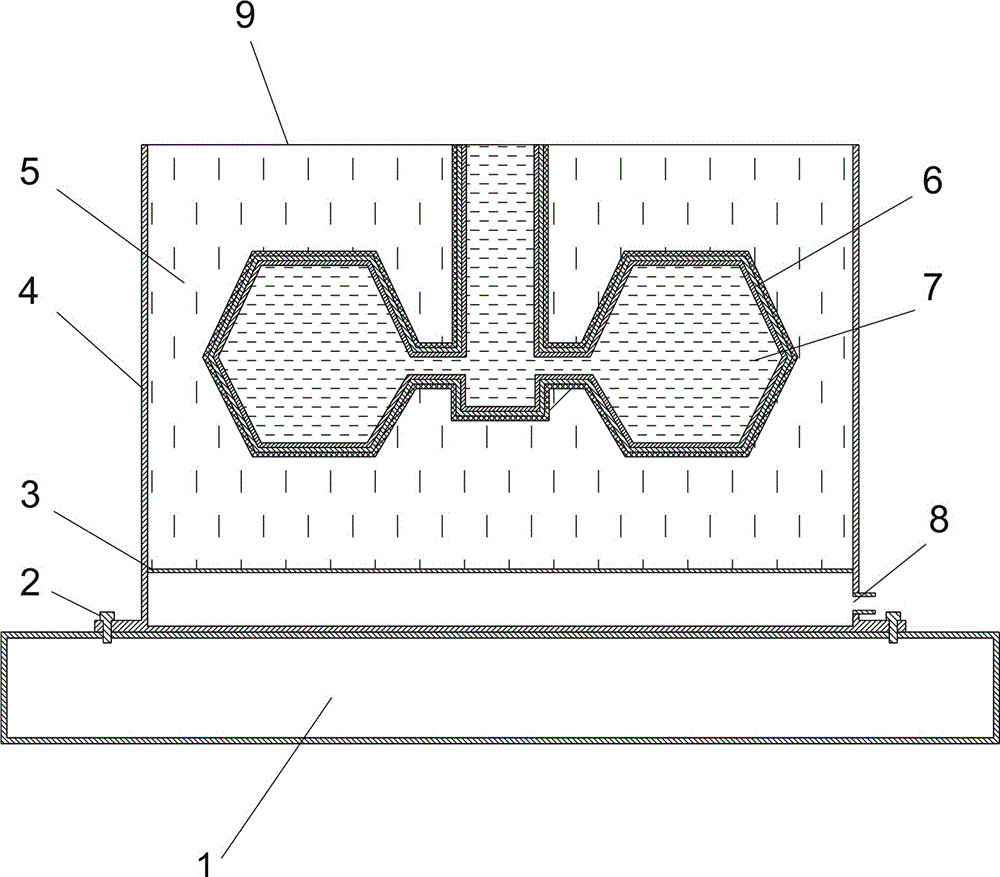

[0020] (2) After losing the foam plastic mold and firing, the ceramic shell 6 is put into the bottom-drawing sand box 4, and the bottom-drawing sand box is connected with the vibrating table through fixing screws 2, and then filled with loose powder into the bottom-drawing sand box. Dry pearl sand 5, after loose dry sand is vibrated and compacted by the vibrating table 1, close the vibrating table, cover the upper part of the sand box with a layer of plastic film 9, and then place the sprue cup on the upper part of the sand box to be poured;

[0021] (3) Turn on the vacuum device and the vibrating table. The vacuum device implements vacuuming through the vacuum port 8 and th...

Embodiment 2

[0023] Vibration Solidification of A356 Aluminum Alloy Lost Form Shell Mold Casting

[0024] (1) Prepare the foam plastic pattern, soak the foam mold with paint, then sprinkle sand, repeat the above operation twice after drying, and form 2 layers of ceramic shells on the surface of the foam mold;

[0025] (2) Ceramic mold shell 6 is put into the bottom-drawing sand box 4 after losing the shape of foam plastic and roasted. The bottom-drawing sand box is connected with the vibrating table through fixing screws 2, and then the bottom-drawing sand box is filled with pearls. Sand 5. After the loose dry sand is vibrated and compacted by the vibrating table 1, the vibrating table is closed, and the upper part of the sand box is covered with a layer of plastic film 9, and then the sprue cup is placed on the upper part of the sand box to be poured;

[0026] (3) Turn on the vacuum device and the vibrating table, and the vacuum device implements vacuuming through the vacuum port 8 and th...

Embodiment 3

[0028] Vibration Solidification of Gray Iron Lost Form Shell Mold Casting

[0029] (1) Prepare the foam plastic pattern, soak the foam mold with paint, then sprinkle sand, repeat the above operation 3 times after drying, and form 3 layers of ceramic shells on the surface of the foam mold;

[0030] (2) After the ceramic mold shell 6 loses the shape of the foam plastic and is roasted, it is put into the bottom-drawing sand box 4, and the bottom-drawing sand box is connected with the vibrating table through the fixing screw 2, and then filled with loose powder into the bottom-drawing sand box. Dry pearl sand 5, after loose dry sand is vibrated and compacted by the vibrating table 1, close the vibrating table, cover the upper part of the sand box with a layer of plastic film 9, and then place the sprue cup on the upper part of the sand box to be poured;

[0031] (3) Turn on the vacuum device and the vibrating table. The vacuum device is vacuumed through the vacuum port 8 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com