Hypoeutectic aluminum-silicon alloy with excellent thermal conductivity, preparation method and application thereof

A thermal conductivity, aluminum-silicon alloy technology, applied in the direction of metal/alloy conductors, conductors, conductive materials, etc., can solve the problems of insufficient thermal conductivity, unable to meet the heat dissipation requirements of miniaturization and multi-function, and achieve low burning loss, The effect of low cost of technological transformation and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

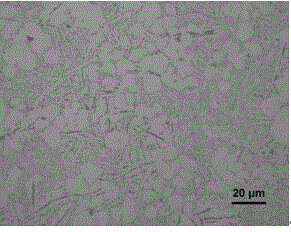

[0048] Below through specific examples and in conjunction with Attached picture The present invention is further elucidated, but not limited.

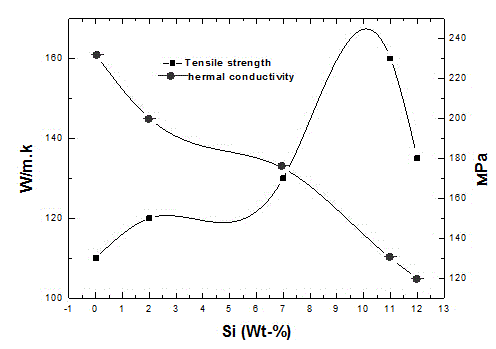

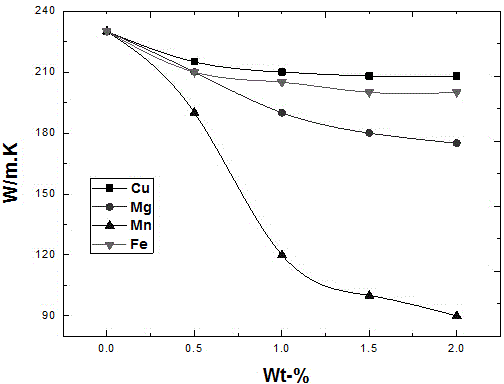

[0049] The present invention provides a hypoeutectic aluminum-silicon alloy material, which has good casting properties, mechanical properties and excellent thermal conductivity. Taking the alloy of the present invention as an example, a test sample is prepared by a metal mold casting process to compare the alloy of the present invention. The thermal conductivity of alloys not in the present invention, in which 1-8# in Table 1 is the alloy not in the present invention, and 9-15# is the alloy in the present invention. Table 2 shows the comparative results of electrical conductivity and thermal conductivity of the alloys of the present invention and alloys not of the present invention.

[0050] The smelting equipment in this embodiment adopts a 10kg electric resistance furnace. Firstly, 99.7% pure aluminum and aluminum-silicon master a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com