Negative carbon steel slag baking-free brick as well as preparation method and application thereof

A non-burning brick and steel slag technology, applied in the field of building materials, can solve the problem of large proportion of cement, and achieve the effect of reducing carbon emissions, saving resources, and low cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

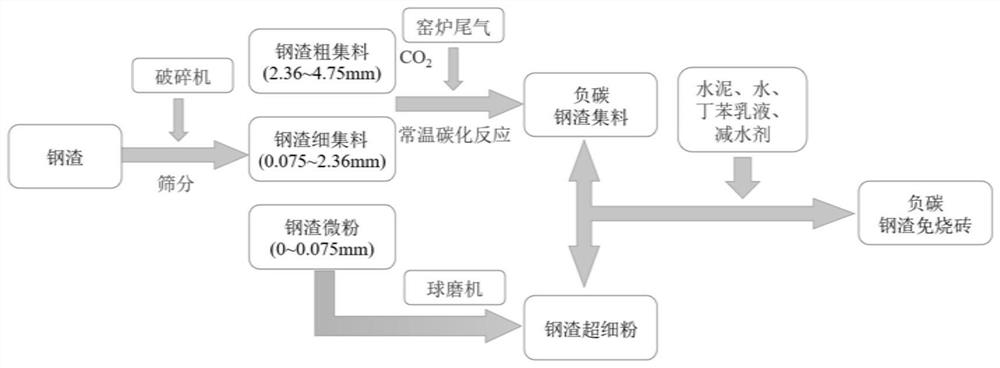

Method used

Image

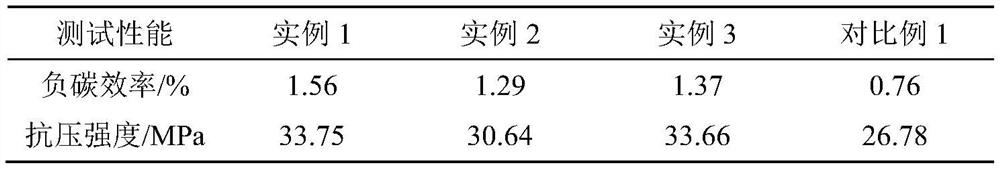

Examples

Embodiment 1

[0030] A preparation method of negative carbon steel slag unfired brick, the steps are as follows:

[0031] (1) The steel slag with a particle size of 0.075mm~4.75mm is divided into coarse aggregate and fine aggregate according to the particle size. The particle size of coarse aggregate is D1, 2.36mm<D1≤4.75mm; fine aggregate is divided into Five grades of gradation, namely first grade material, second grade material, third grade material, fourth grade material and fifth grade material; the particle size of the first grade material is d1, 0.075mm≤d1≤0.15mm; the second grade material The particle size of the material is d2, 0.15mm<d2≤0.3mm; the particle size of the third-grade material is d3, 0.3mm<d3≤0.6mm; the particle size of the fourth-grade material is d4, 0.6mm<d4≤ 1.18mm; the particle size of the fifth grade material is d5, 1.18mm<d5≤2.36mm;

[0032] (2) Place the first-grade material, second-grade material, third-grade material, fourth-grade material, fifth-grade mater...

Embodiment 2

[0035] A preparation method of negative carbon steel slag unfired brick, the steps are as follows:

[0036] (1) The steel slag with a particle size of 0.075mm~4.75mm is divided into coarse aggregate and fine aggregate according to the particle size. The particle size of coarse aggregate is D1, 2.36mm<D1≤4.75mm; fine aggregate is divided into Five grades of gradation, namely first grade material, second grade material, third grade material, fourth grade material and fifth grade material; the particle size of the first grade material is d1, 0.075mm≤d1≤0.15mm; the second grade material The particle size of the material is d2, 0.15mm<d2≤0.3mm; the particle size of the third-grade material is d3, 0.3mm<d3≤0.6mm; the particle size of the fourth-grade material is d4, 0.6mm<d4≤ 1.18mm; the particle size of the fifth grade material is d5, 1.18mm<d5≤2.36mm;

[0037](2) Place the first-grade material, second-grade material, third-grade material, fourth-grade material, fifth-grade materi...

Embodiment 3

[0040] A preparation method of negative carbon steel slag unfired brick, the steps are as follows:

[0041] (1) The steel slag with a particle size of 0.075mm~4.75mm is divided into coarse aggregate and fine aggregate according to the particle size. The particle size of coarse aggregate is D1, 2.36mm<D1≤4.75mm; fine aggregate is divided into Five grades of gradation, namely primary material, secondary material, third-grade material, fourth-grade material and fifth-grade material; the particle size of the first-grade material is d1, 0.075mm≤d1≤0.15mm; the second-grade material The particle size of the material is d2, 0.15mm<d2≤0.3mm; the particle size of the third-grade material is d3, 0.3mm<d3≤0.6mm; the particle size of the fourth-grade material is d4, 0.6mm<d4≤ 1.18mm; the particle size of the fifth grade material is d5, 1.18mm<d5≤2.36mm;

[0042] (2) Place the first-grade material, second-grade material, third-grade material, fourth-grade material, fifth-grade material, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com