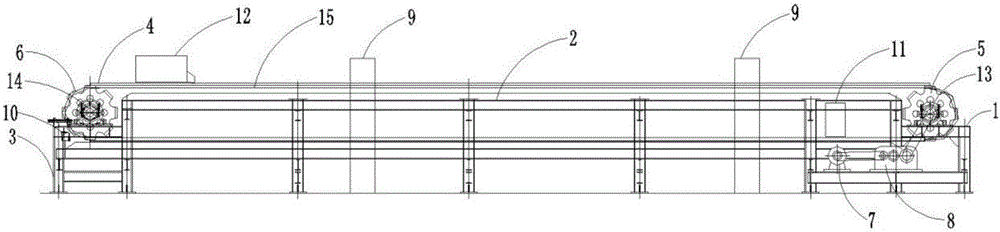

Continuous casting machine

A casting machine and machine head technology, applied in casting equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve problems such as water leakage, mold damage, motor burnout, etc., to protect the mold and transmission system, reduce Maintenance costs and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

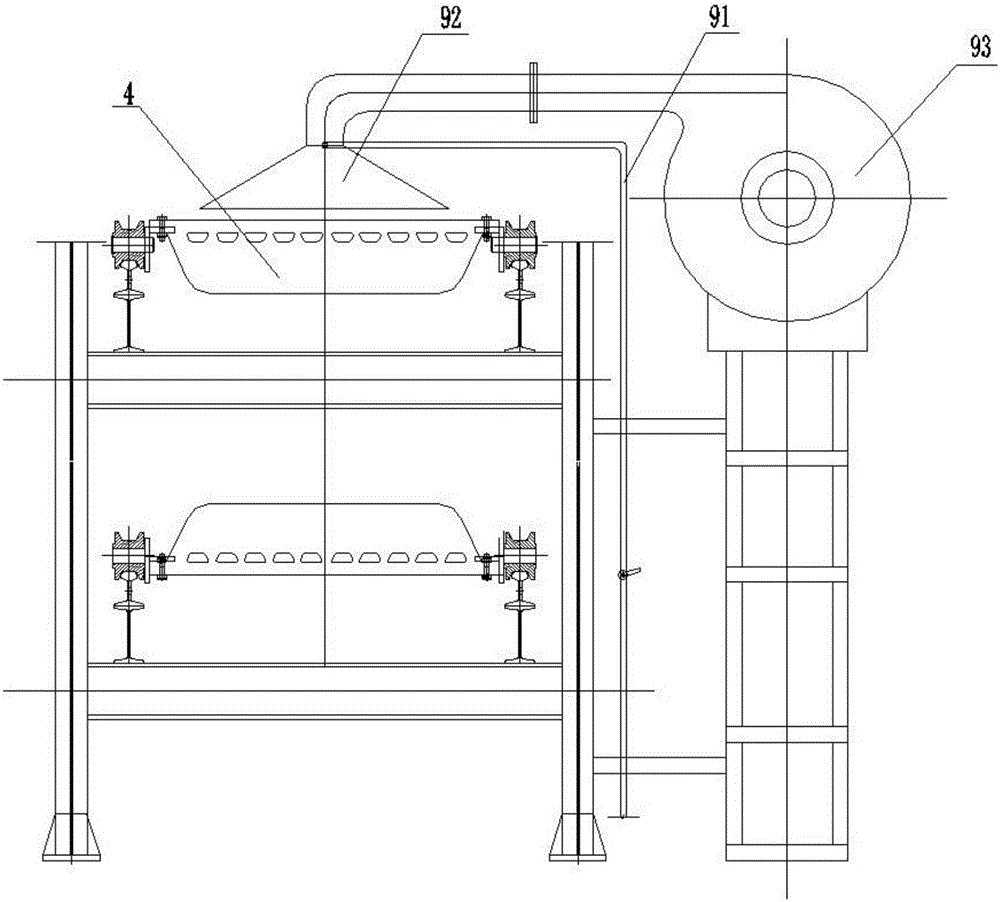

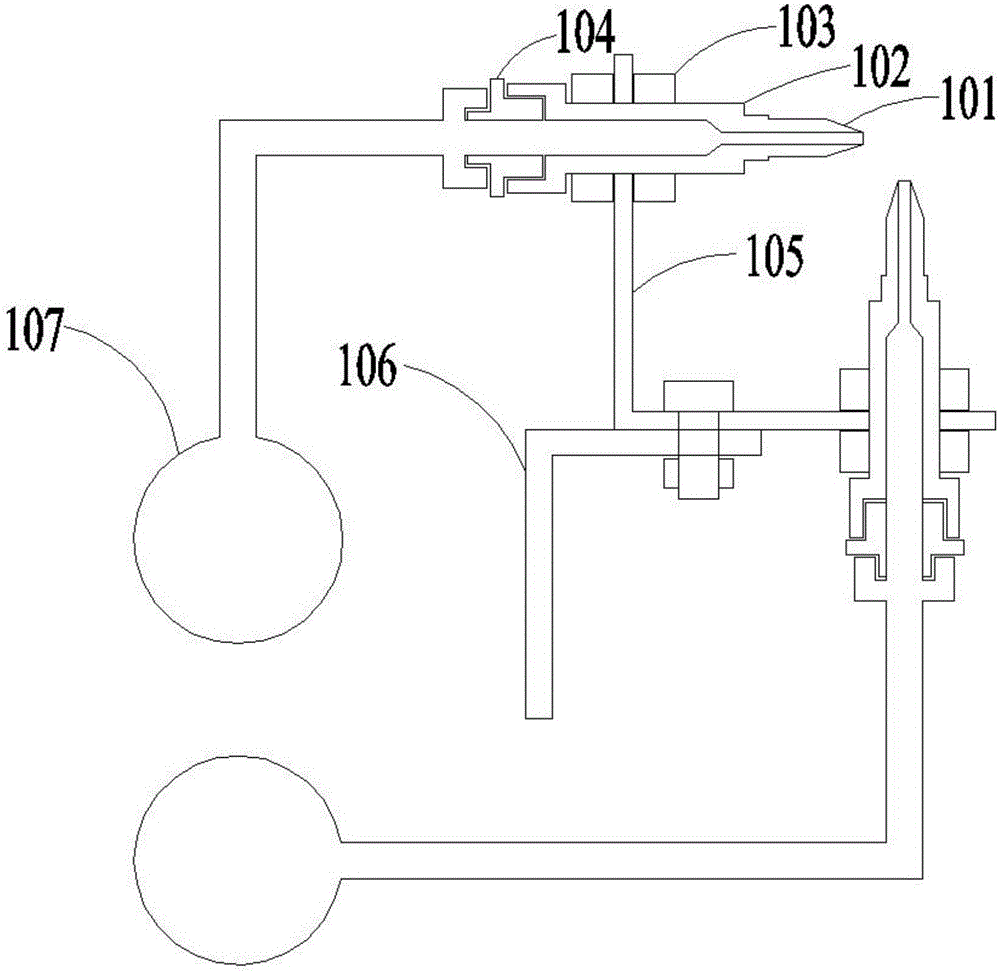

[0020] After starting up, the motor rotates and transmits to the reducer. The reducer drives the drive shaft of the machine head through the coupling. The drive shaft of the machine head drives the drive sprocket of the machine head. With the closed transmission structure, the mold fixedly installed on the transmission chain also runs accordingly. The mold first passes through the release agent spraying device at the rear of the tailstock, sprays a layer of release agent on the surface of the mold, and then transfers to the bottom of the casting port. The molten steel in the ladle is buffered by the casting port, flows evenly into the mold that has been sprayed with release agent, and then slowly runs towards the head frame, passing through two cooling devices during the process, and the cooling water in the cooling device passes through the axial flow fan The blown gas is evenly sprayed on the mold and the alloy ingot in the mold to realize the rapid cooling of the mold and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com