Simple composite material grid workpiece forming method

A composite material and molding method technology, applied in the direction of nets, other household appliances, household appliances, etc., can solve the problems of large investment in the molding process, high cost of raw materials, and high design difficulty, and achieve low requirements for winding equipment, low cost, and winding equipment. ask for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

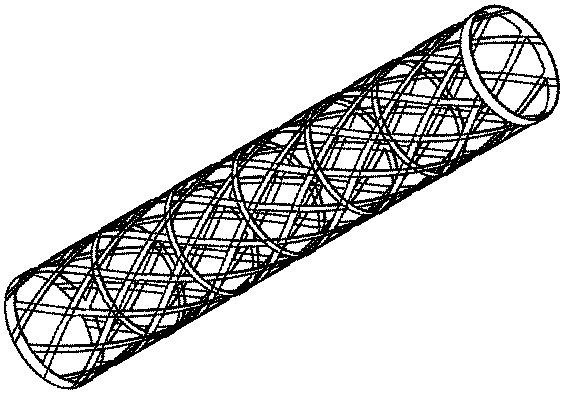

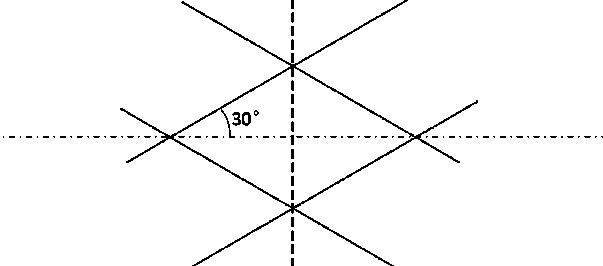

[0024] to attach figure 1 Take the grid structure unit as an example, assuming that the inner diameter of the formed grid structure product is 138mm, the length is 600mm, and the thickness of the rib is 2mm. The grid structure unit is as follows figure 2 As shown, the wrapping angle is 30°.

[0025] The mold is 1m long, 138mm in diameter, with heads at both ends, which can realize 30° geodesic winding. There is no slot in the mold barrel, and there is a circumferential cutting groove about 2mm wide and 2mm deep at the junction of the head and the barrel. The specific molding method includes the following steps:

[0026] (1) Mold preparation: Wipe the mold surface with a rag dipped in acetone to remove oil and impurities on the mold surface. After the acetone has evaporated, apply a mold release agent evenly on the mold surface for 2 times. After the mold dries for 30 minutes, install the mold on the winding on board;

[0027] (2) Material preparation: place the fibers in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com