Tools and method for measuring thickness of drill pile hole bottom grain stillage

A technology of slag thickness and hole bottom, applied in mechanical thickness measurement, mechanical depth measurement and other directions, which can solve the problems of inability to make objective measurement judgment and misjudgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

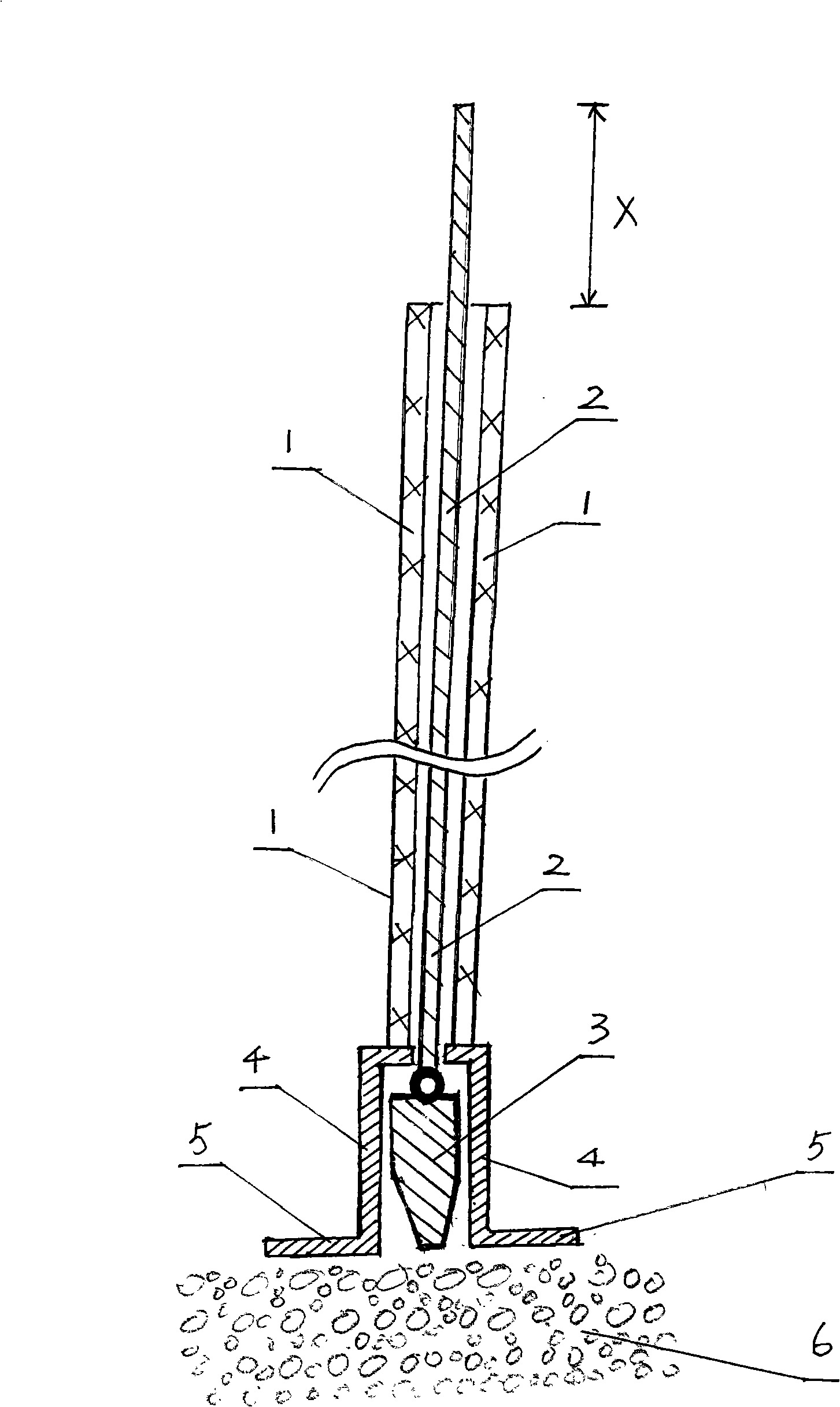

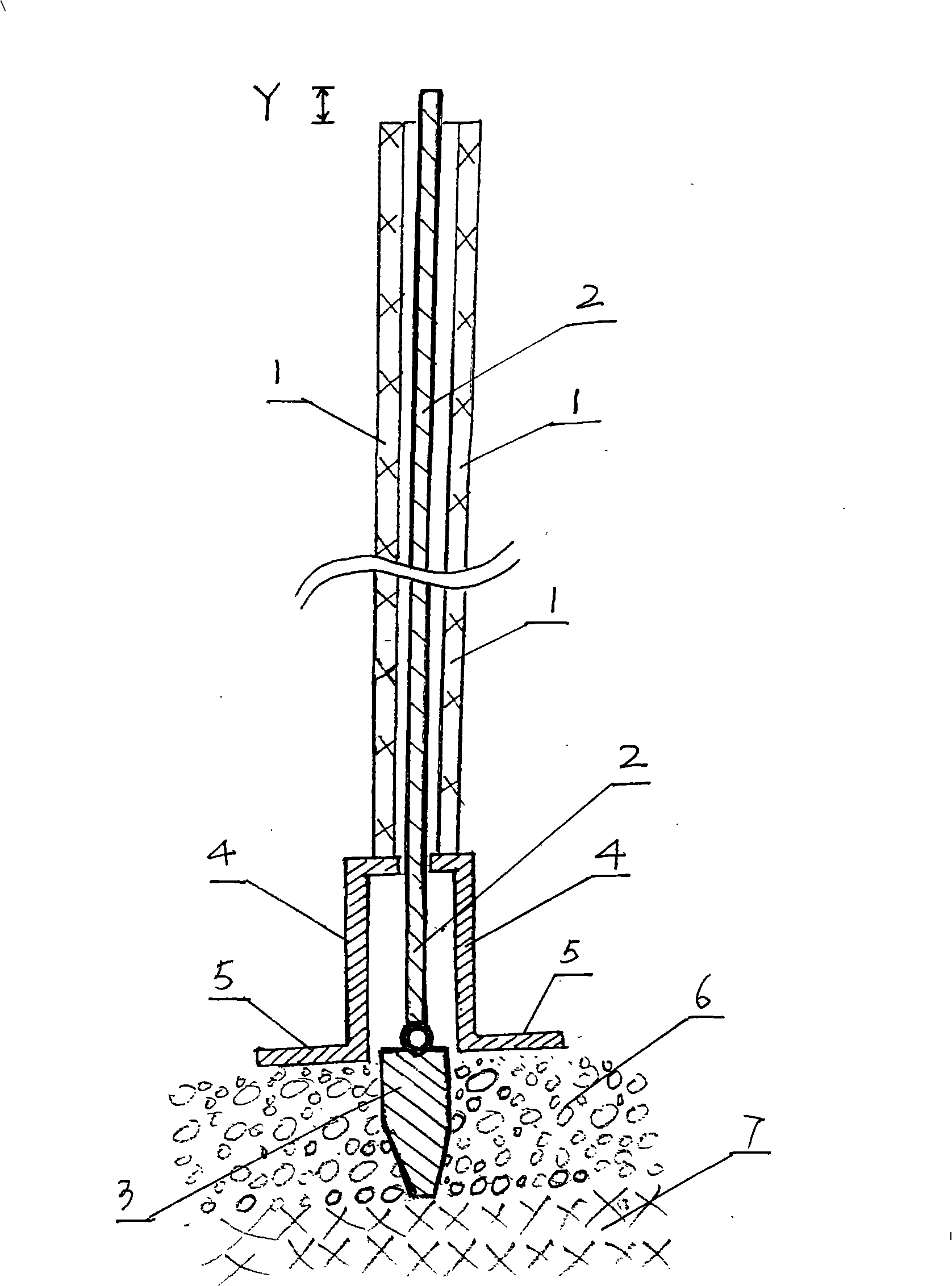

[0011] Such as figure 1 As shown, the tool for measuring the thickness of sediment at the bottom of the bored pile hole includes a measuring rope. The measuring rope is composed of an outer layer 1 and a core layer 2. The outer layer 1 is loosely sleeved around the core layer 2, and is tied at the bottom end of the measuring rope. There is a metal measuring hammer 3, which is tied to the lower end of the measuring rope core layer 2; the lower end of the measuring rope outer layer 1 is connected with a vertical sleeve 4, and the lower end of the vertical sleeve 4 is provided with a horizontal film 5, The directional sleeve 4 and the horizontal bottom plate 5 are fixedly connected as a whole; the metal measuring hammer 3 is loosely sleeved in the vertical sleeve 4; the upper end of the core layer 2 is exposed outside the outer layer 1; the upper end of the measuring rope core layer 2 is provided with a scale .

Embodiment 2

[0013] Such as figure 1 , figure 2 As shown, the method for measuring the thickness of sediment at the bottom of a bored pile hole adopts the measuring tool of embodiment 1, and includes the following steps: a. Before placing the metal measuring hammer 3 to the bottom of the pile hole, adjust the metal measuring hammer 3 and the vertical sleeve 4 Make the bottom end of the metal test hammer 3 and the horizontal film 5 flush, and record the length X of the upper end of the test rope core layer 2 exposed outside the outer cover layer 1; b. Hold the upper end of the test rope 1 and face the bottom of the pile hole Put down the metal stylus 3 until the bottom of the metal stylus 3 and the horizontal plate contact the bottom sediment 6 of the hole; c. Continue to make the metal stylus penetrate the sediment layer 6, and the lower end of the metal stylus touches the bearing layer (rock layer) 7 , And the horizontal film 5 is blocked on the sediment layer 6, so that the core layer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com