Method for testing physical performances of film and film-substrate interface based on nanometer indentation continuous stiffness curve

A technology of physical properties and nano-indentation, applied in the direction of mechanical thickness measurement, testing material hardness, etc., to achieve a wide range of applications, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

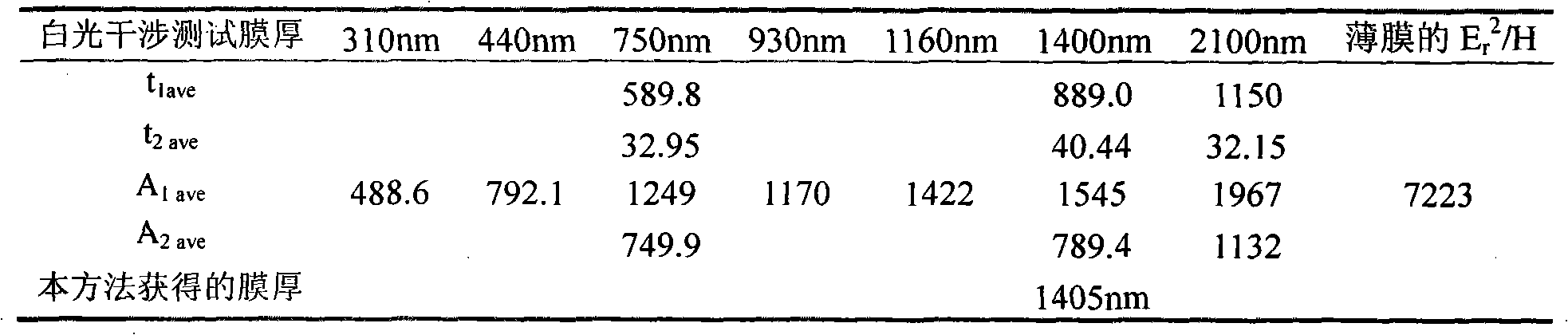

[0020] Embodiment 1: The tested sample is a glass-based titanium film, and the samples used for calibration are glass-based titanium films with a film thickness of 750nm and a film thickness of 2100nm, see Table (1). The sample used to test the thickness is a sample with a film thickness of 1400nm. It is assumed that the known thickness samples are glass-based titanium films with a film thickness of 750nm and a film thickness of 2100nm. These two film thicknesses are randomly selected. The titanium film with a film thickness of 1400nm is the sample to be tested, and the film thickness is assumed to be unknown. The glass is all commercial white float glass. Titanium films were prepared by magnetron sputtering. Use the following methods to analyze and test relevant physical properties:

[0021] (1) Do nanoindentation experiments on solid film samples, choose the continuous stiffness method, and repeat three times for each sample;

[0022] (2) Obtain the relationship curve of ...

Embodiment 2

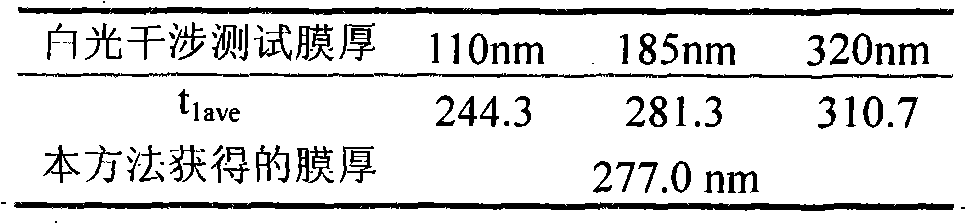

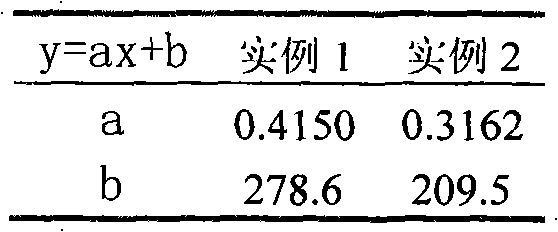

[0029] Embodiment 2: The sample to be tested is a glass-based titanium nitride film, and the samples used for calibration are glass-based titanium nitride with a film thickness of 110 nm and a film thickness of 320 nm. The sample used to test the thickness is a sample with a film thickness of 185nm. It is assumed that the known thickness samples are 110nm film thickness and 320nm film thickness, these two film thicknesses are randomly selected, and the 185nm sample is the tested sample, assuming that the film thickness is unknown. The glass is all commercial white float glass. Titanium nitride films were prepared by magnetron sputtering. The operation steps are the same as those in Example 1, see Table (3) for obtaining a and b, and see Table (2) for the film thickness obtained by testing.

Embodiment 3

[0030] Example 3: The tested samples are glass-based titanium films, and the film thicknesses are 310nm, 440nm, 750nm, 930nm, 1160nm, 1400nm, 2100nm, see Table (1). The glass is all commercial white float glass. Titanium films were prepared by magnetron sputtering. Use the following methods to analyze and test relevant physical properties:

[0031] (1) Do nanoindentation experiments on solid film samples, choose the continuous stiffness method, and repeat three times for each sample;

[0032] (2) Obtain the relationship curve of the hardness and elastic modulus of the material with the indentation depth through the loading curve;

[0033] (3) will E r 2 / H is used as the ordinate, and the indentation depth h is used as the abscissa, and the fitting is carried out by formula (1), and the fitting range is 20nm to 2400nm;

[0034] (4) Process the original data according to the iterative screening least squares method: after the first fitting, the trend line is used as the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com