Spacer thickness measuring instrument

A technology of thickness measurement and gasket, which is applied in the field of thickness measurement devices, can solve the problems of large measurement errors, etc., and achieve the effects of simple and practical structure, high repeatability and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

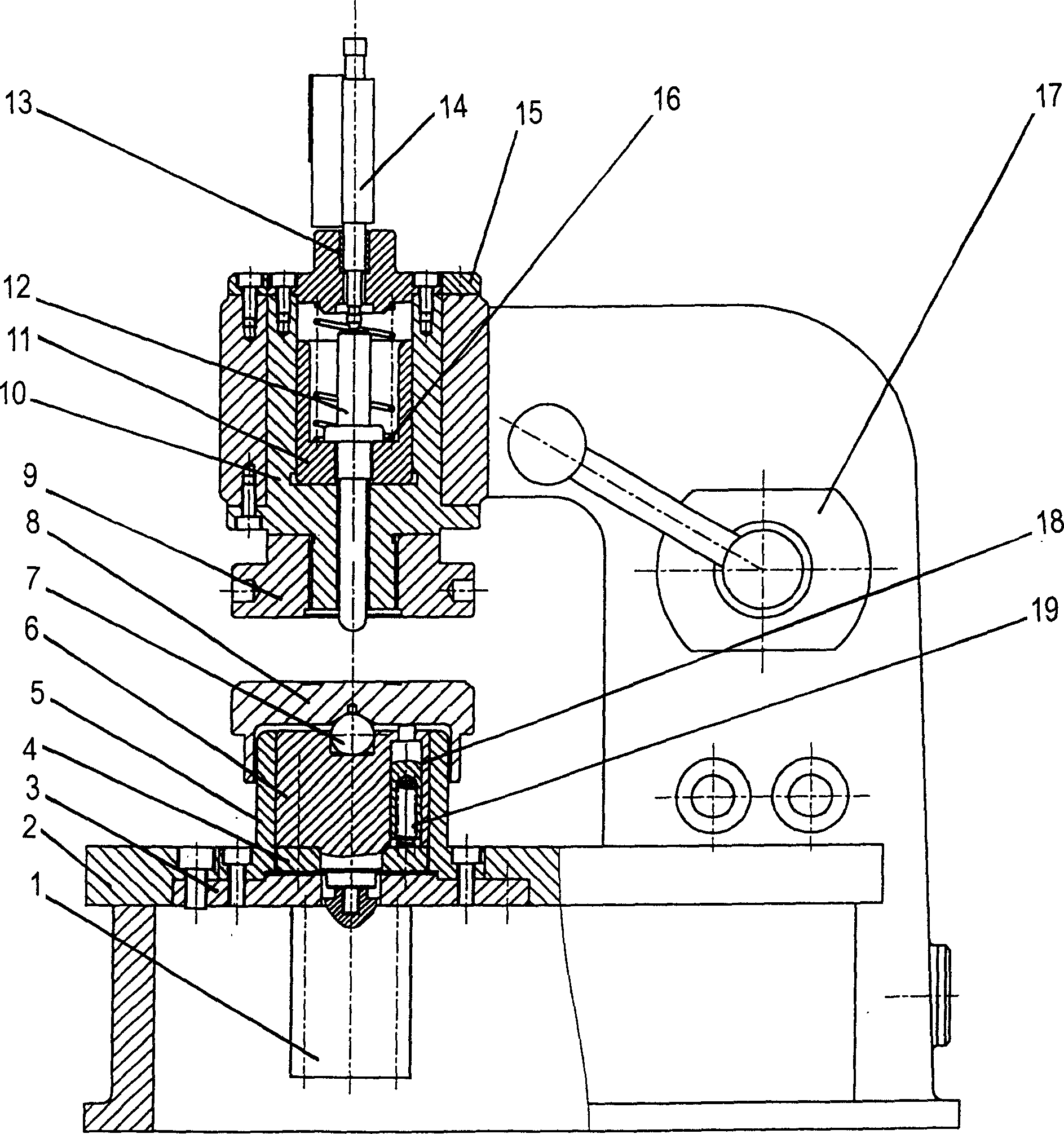

[0015] Referring to the accompanying drawings, the present embodiment is provided with a splint-shaped measuring head. The splint-shaped measuring head is composed of a bottom measuring platform 8 and a measuring platen 9 above the measuring platform 8. The gasket is placed between the measuring platform 8 and the measuring platen 9. The measuring platform 8 is an axially moving member, and the shaft-shift measuring rod 12 is arranged along the axial direction of the measuring platen 9. The measuring head of the dial indicator 14 is against the top end face of the shaft-shift measuring rod 12, and the bottom end face of the shaft-shift measuring rod 12 extends toward the measurement The platform 8 is accessible to the measurement platform 8, and the axis displacement measuring rod 12 uses the measurement platform 8 as a sensing surface.

[0016] As shown in the figure, in this embodiment, the axial movement of the measurement platform 8 adopts a pneumatic control method, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com