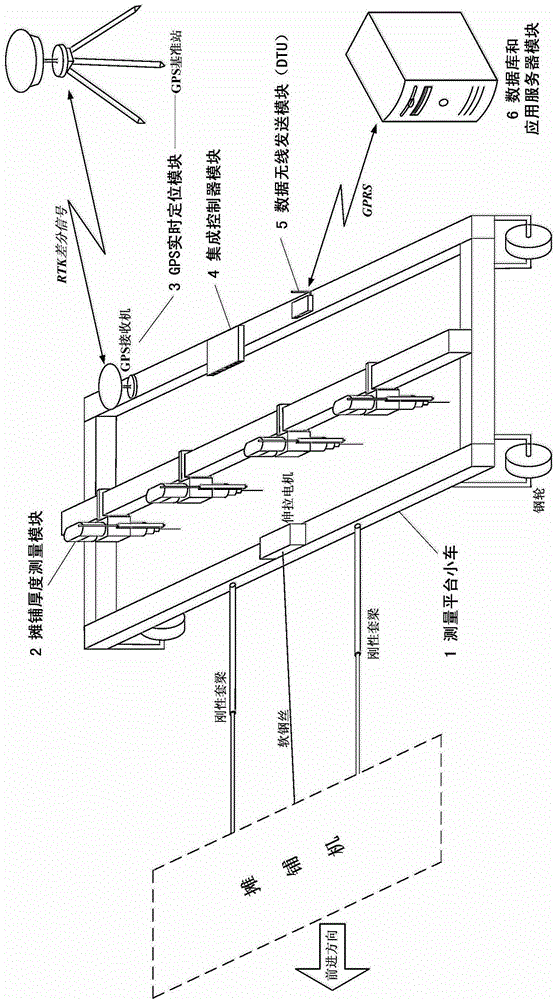

Highway pavement paving thickness plug-in automatic measuring device

An automatic measurement and thickness measurement technology, applied in the direction of mechanical thickness measurement, roads, roads, etc., can solve the problems of poor representativeness, error in detection results, inability to intuitively and accurately indicate the absolute position of the road surface, etc., to reduce one-sidedness, real-time collection, The effect of facilitating quality recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

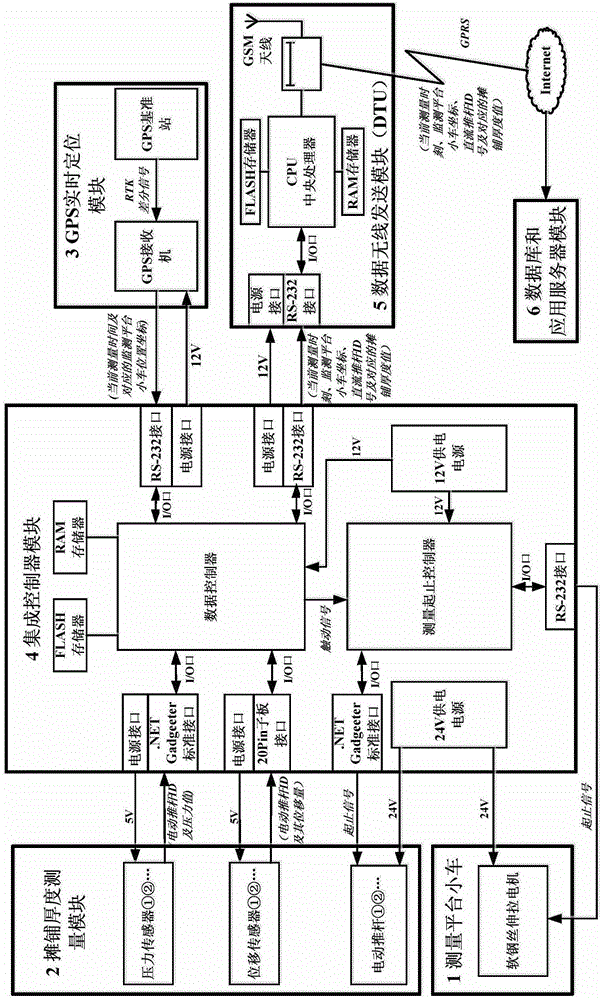

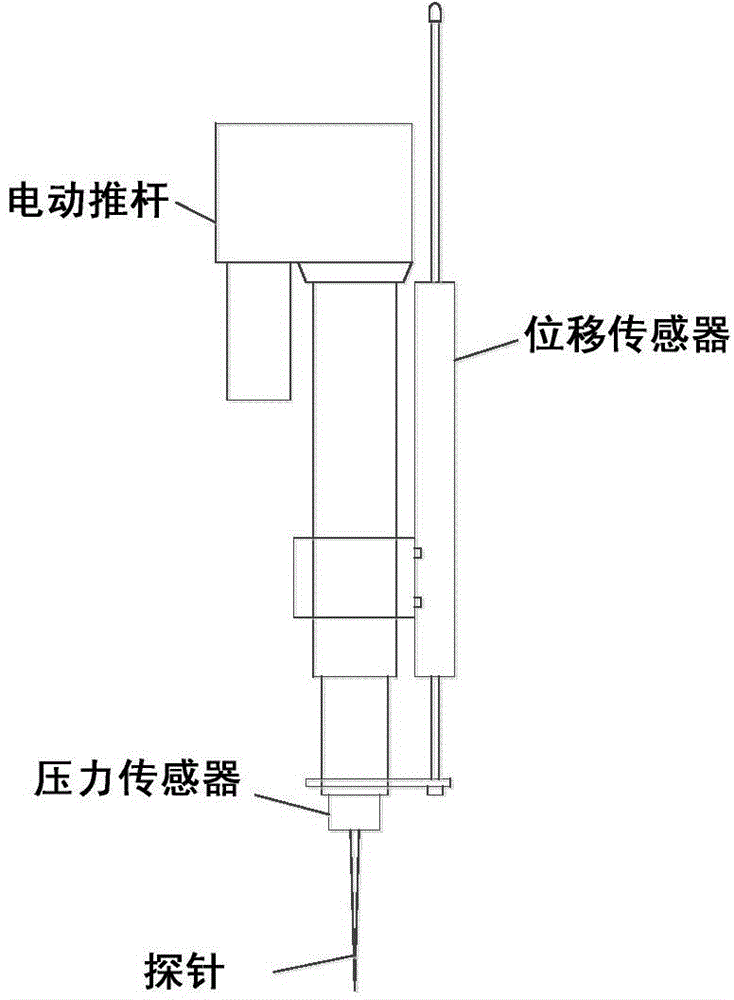

[0030]The present invention is further developed on the basis of the patent "a real-time monitoring system for pavement thickness of high-grade road pavement (application number 201410057420.3)" applied by the research group earlier, in which the data wireless transmission module (DTU) in the present invention is the same as that of the previous The applied patent (application number 201410057420.3) is similar; the difference is that the previously applied patent mainly uses the automatic tracking total station (measuring robot) to measure the pavement elevation model before and after the pavement structural layer is paved, and then obtains the paving after making a difference thickness, and the present invention uses the electric push rod to drive the displacement sensor to insert the road paving material, and the pressure sensor at the front end of the push rod measures the displacement extension corresponding to the pressure value of the paving surface and the base surface to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com