Excessive concrete pouring detector for underwater cast-in-place piles and method for using excessive concrete pouring detector

An underwater pouring and detector technology, which is applied in the direction of mechanical thickness measurement, construction, and infrastructure engineering, can solve the problems of increasing the amount of pile head removal, inaccurate results, and high concrete overfilling height, so as to reduce potential safety hazards The effect of generating, reducing waste, and preventing dirty cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The underwater cast-in-situ pile concrete overfilling detector and its use method of the present invention will be described in detail below in conjunction with the accompanying drawings.

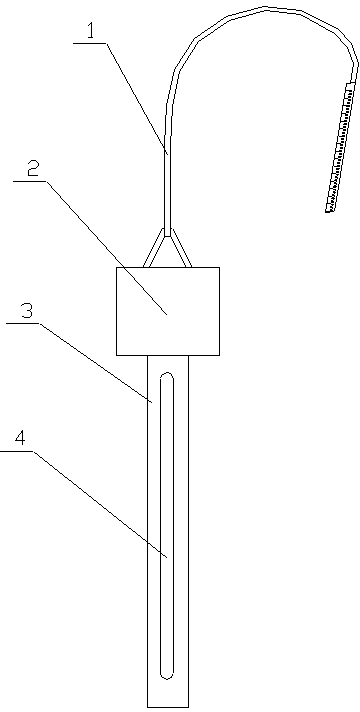

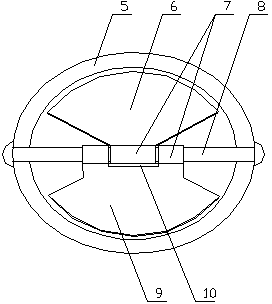

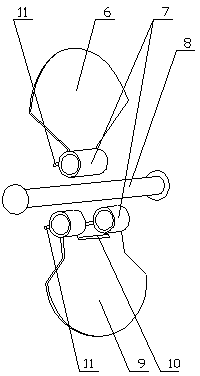

[0021] Such as Figure 1-3 As shown, the underwater pouring pile concrete overfilling detector of the present invention and its use method, the underwater pouring pile concrete overfilling detector is composed of a measuring rope 1, a counterweight ring 2, a coring cylinder 3 and a check valve. The lower end of the measuring rope 1 is fixedly connected with the counterweight ring 2, the other end of the measuring rope 1 is connected with a tape measure, the lower end of the counterweight ring 2 is fixedly connected with the coring cylinder 3, and the lower end of the coring cylinder 3 is set to be sharp The knife edge is convenient for the core cylinder 3 to sink into the detection object. The side wall of the core cylinder 3 is provided with a transparent observation window 4. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com