Continuous enveloping fluidized bed for slow/control-release fertilizers

A technology of coated fluidized bed and controlled-release fertilizers, which is applied in the direction of chemical instruments and methods, chemical/physical processes, powder suspension method granulation, etc. Problems such as poor slow-release effect of urea and low nutrient content, to achieve the effects of improving labor production efficiency and economic benefits, reducing energy consumption, and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

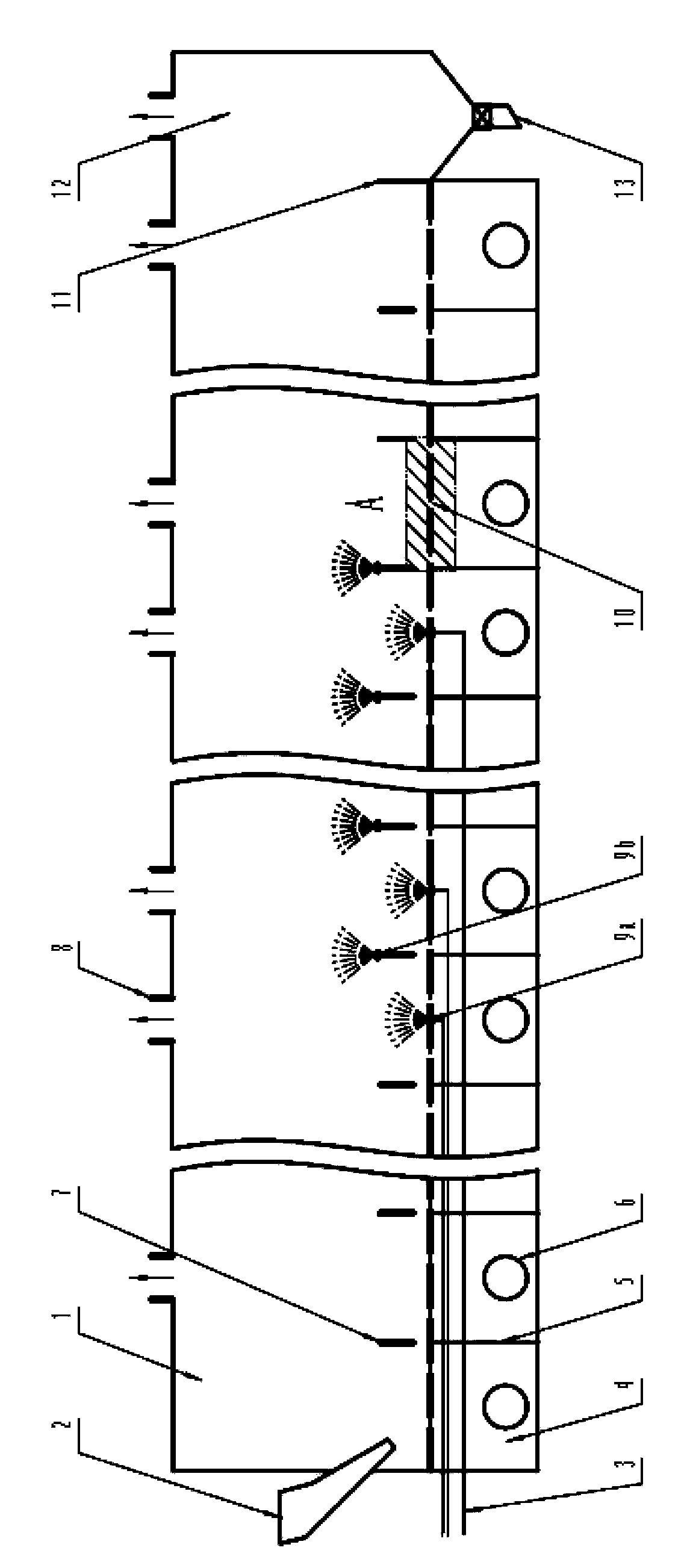

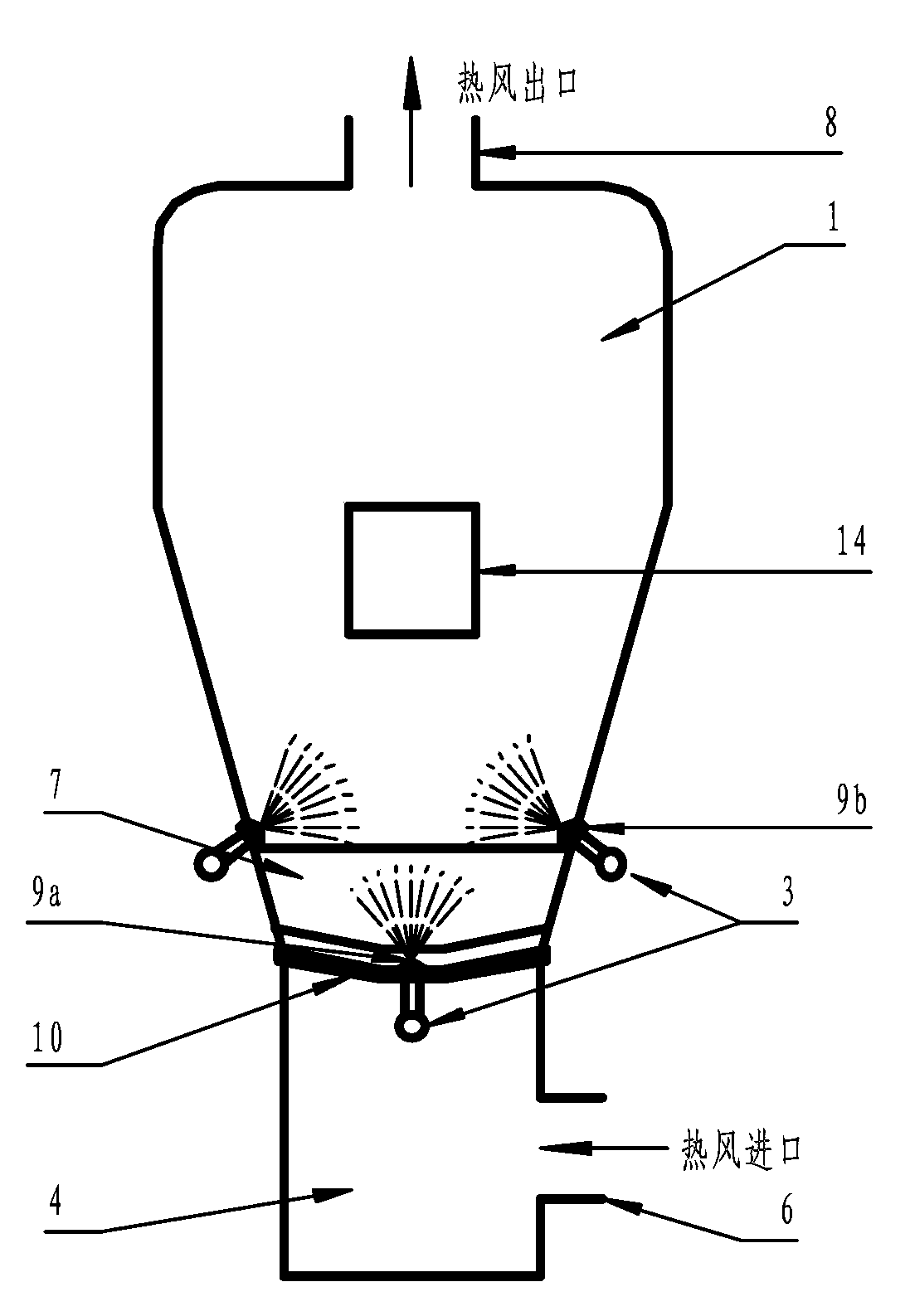

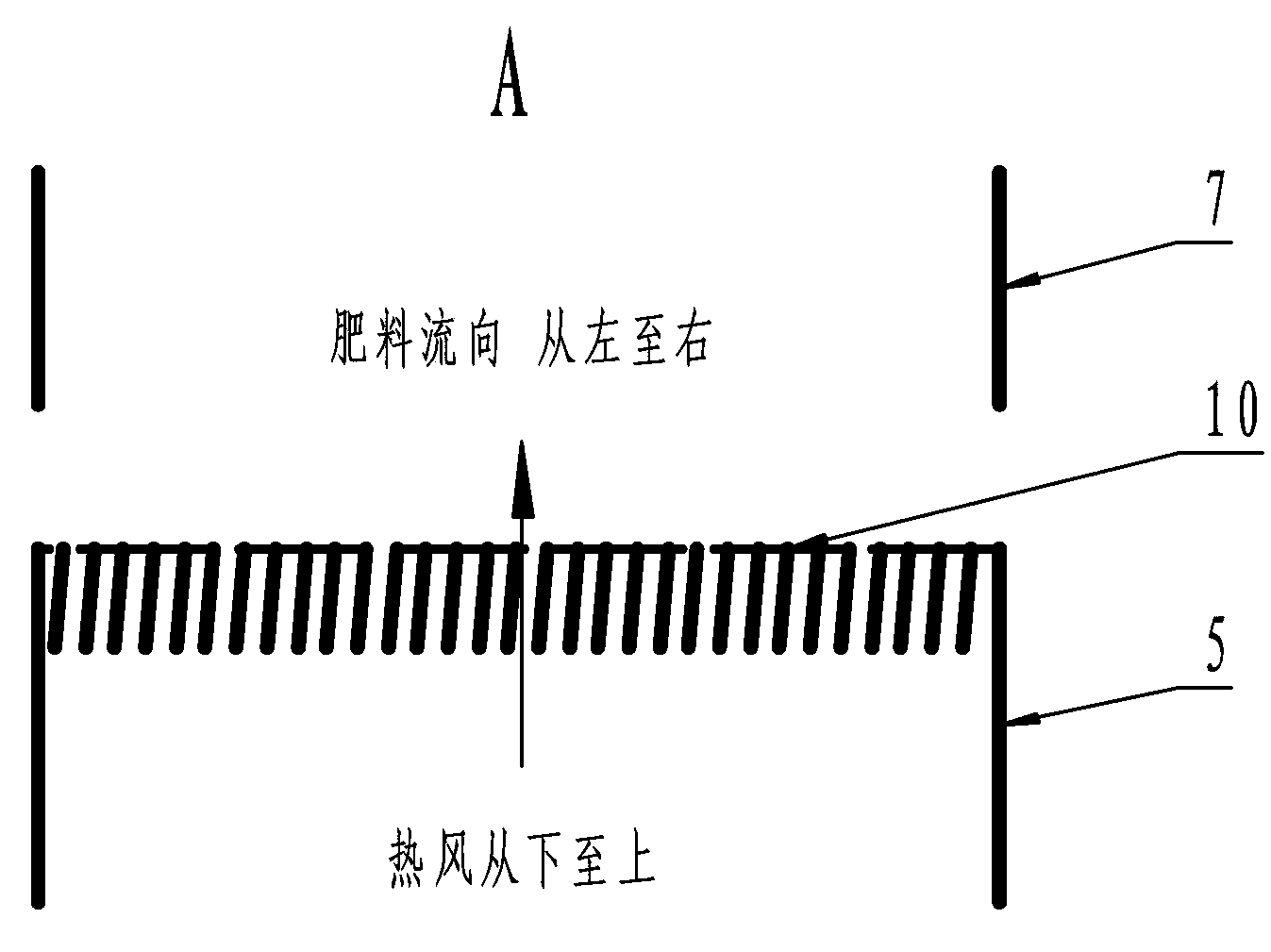

[0019] Such as figure 1 , figure 2 and image 3 As shown, a continuous coated fluidized bed for slow / controlled release fertilizers includes a bed body 1, an air distribution screen 10, an air inlet pipe 6 and an air outlet pipe 7, a feed pipe 3, a bottom spray gun 9a and a side Spray gun 9b, bed body 1 is designed to be horizontal, composed of multiple parallel fluidization chambers and a discharge bin 12, and the parallel fluidization chambers are divided into preheating section, coating section and drying section sequentially from feeding port 2 , each fluidization chamber is separated from each other by an air chamber partition 5 and a suspension partition 7, the first fluidization chamber is provided with a feeding port 2, the discharge bin 12 is arranged at the tail of the bed body, and a discharge port is provided below 13. The airflow distribution screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com