Gasket measuring and matching check tool

A technology of checking fixtures and gaskets, which is applied in the field of gasket measurement and matching checking fixtures, can solve problems such as time-consuming and inaccurate, and achieve the effects of eliminating free gaps, easy operation, and accurate selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

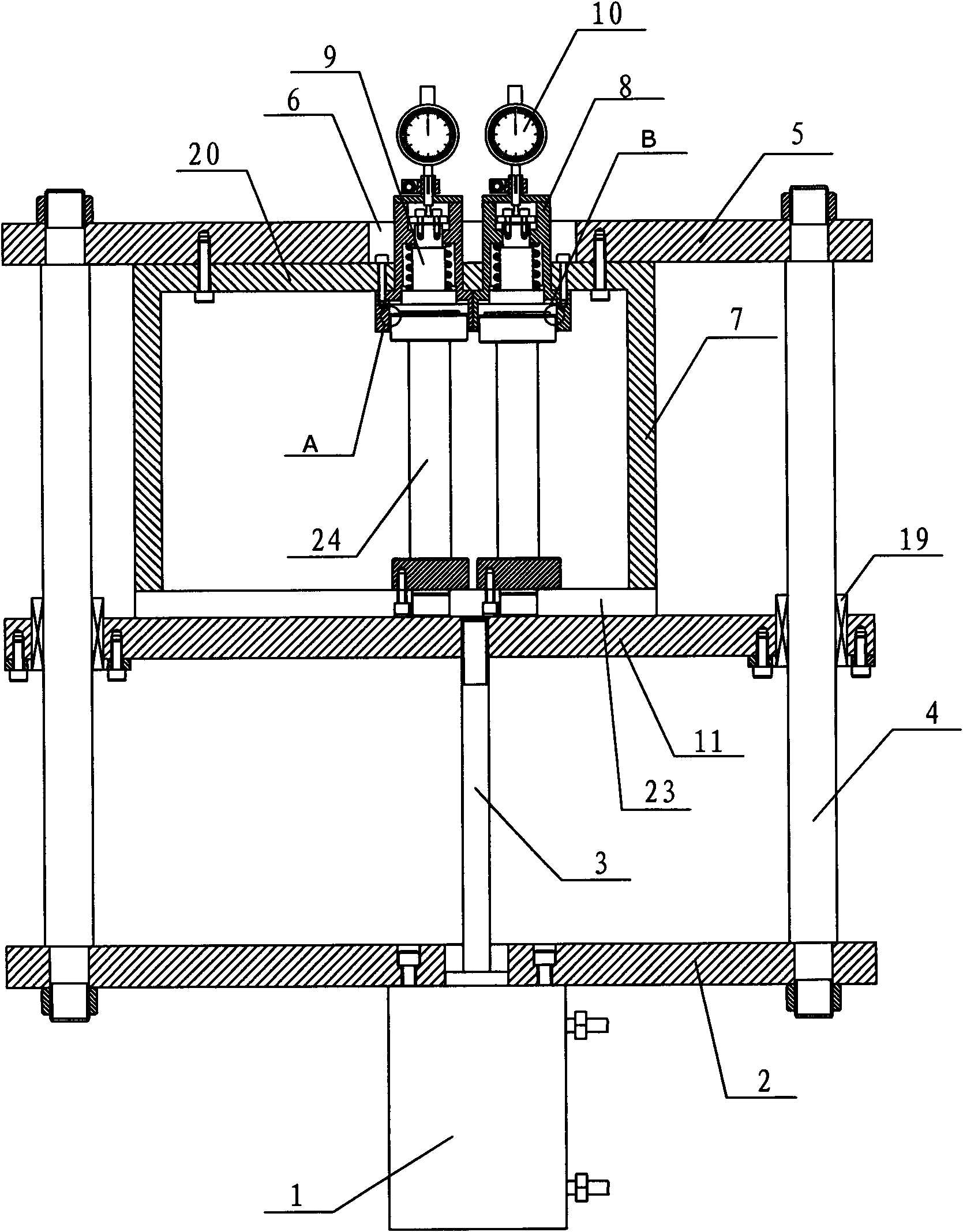

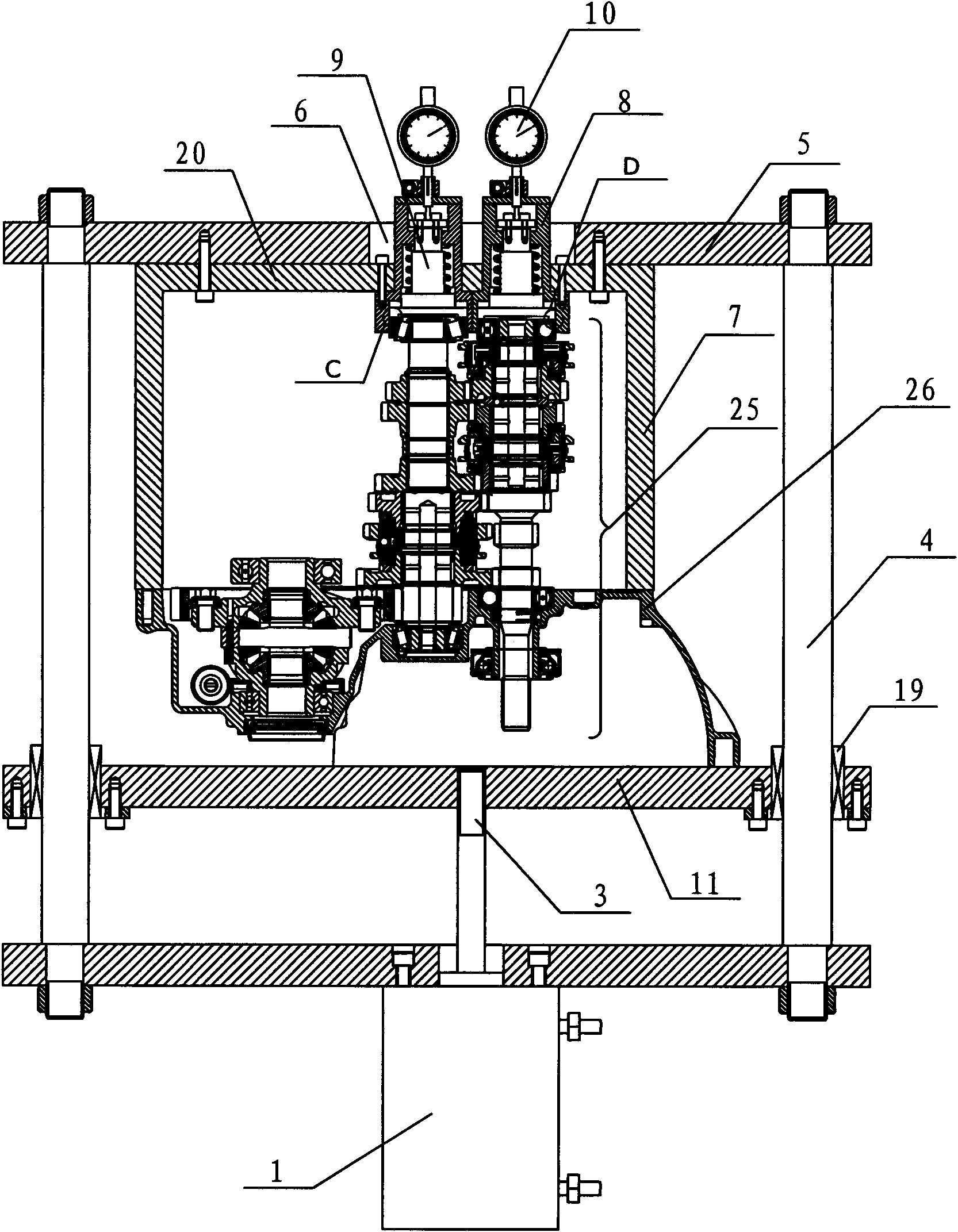

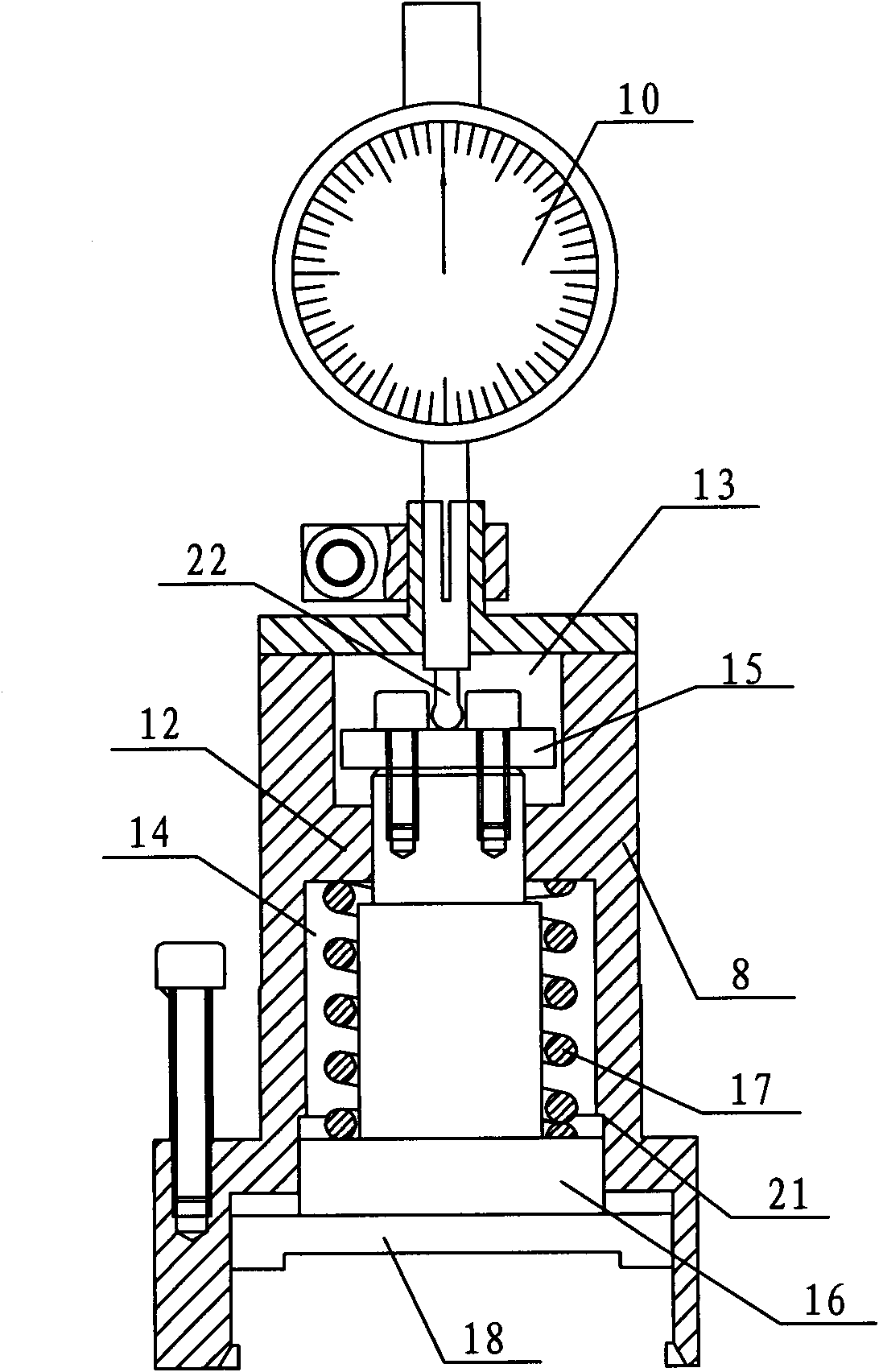

[0024] Such as Figure 1~3 As shown, an optional inspection tool for gasket measurement includes a cylinder 1 and a horizontally installed inspection tool bottom plate 2 fixed on the upper end of the cylinder 1. The push rod 3 of the cylinder 1 passes through the inspection tool bottom plate 2 vertically. Two vertically upward inspection tool guide posts 4 are arranged on the side; the upper end of the inspection tool guide post 4 is fixed with a horizontally installed inspection tool top plate 5, and a through hole 6 is provided on the inspection tool top plate 5; the lower side of the inspection tool top plate 5 An inverted U-shaped gauge measuring block is fixed on the top; two gauge positioning sleeves 8 that pass through the inverted U-shaped gauge measuring block and the through hole 6 on the gauge top plate 5 are fixed on the upper side of the inverted U-shaped gauge measuring block ; The inspection tool positioning sleeve 8 is respectively provided with the inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com