Distribution selector

A rack and lithium battery technology, applied in the field of matching machines, can solve the problems of high manufacturing cost, many pneumatic components, production and sales losses, etc., and achieve the effects of reducing the number of operators, high degree of automation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

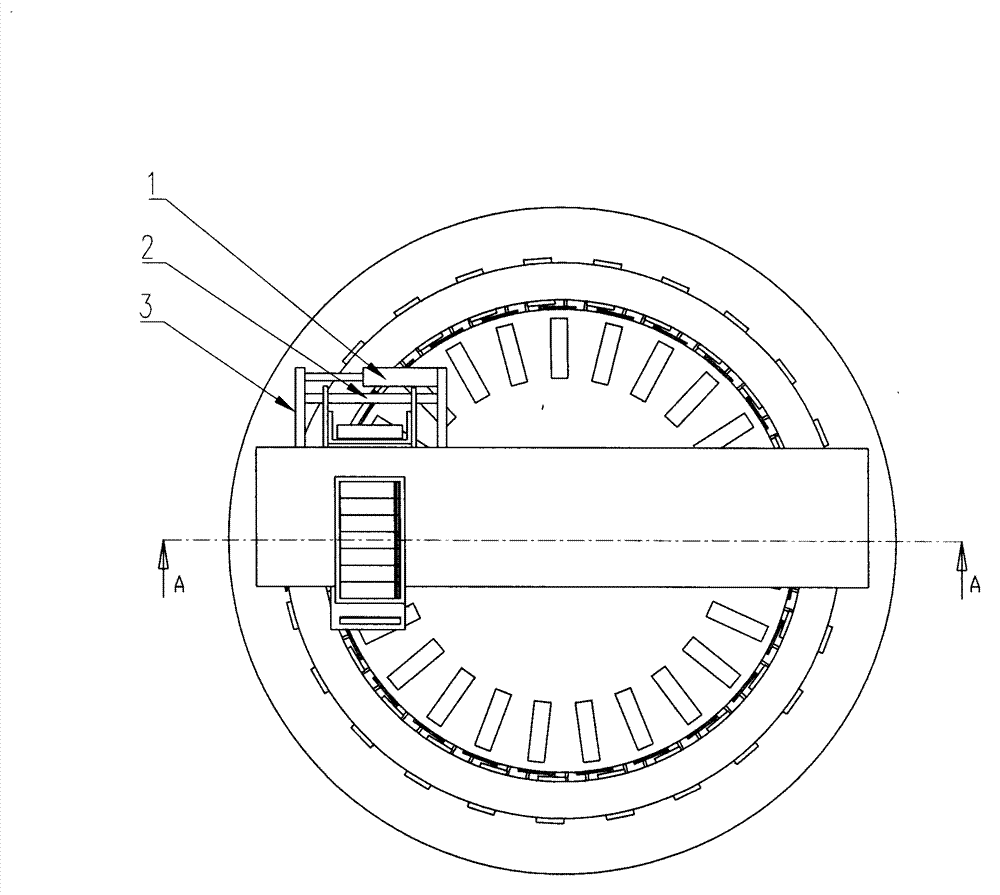

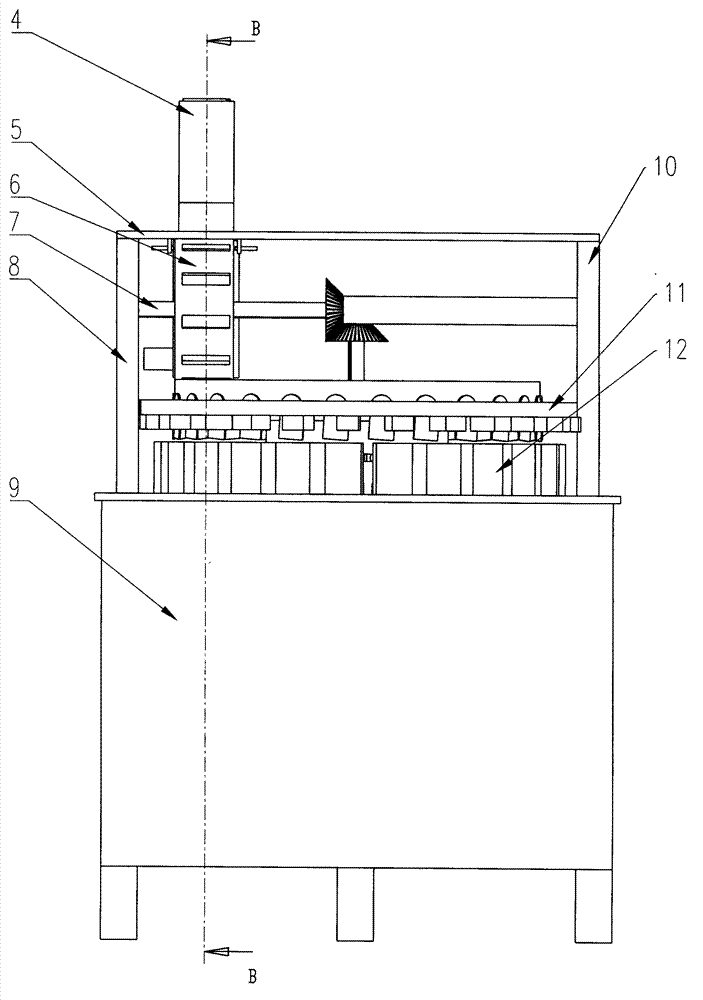

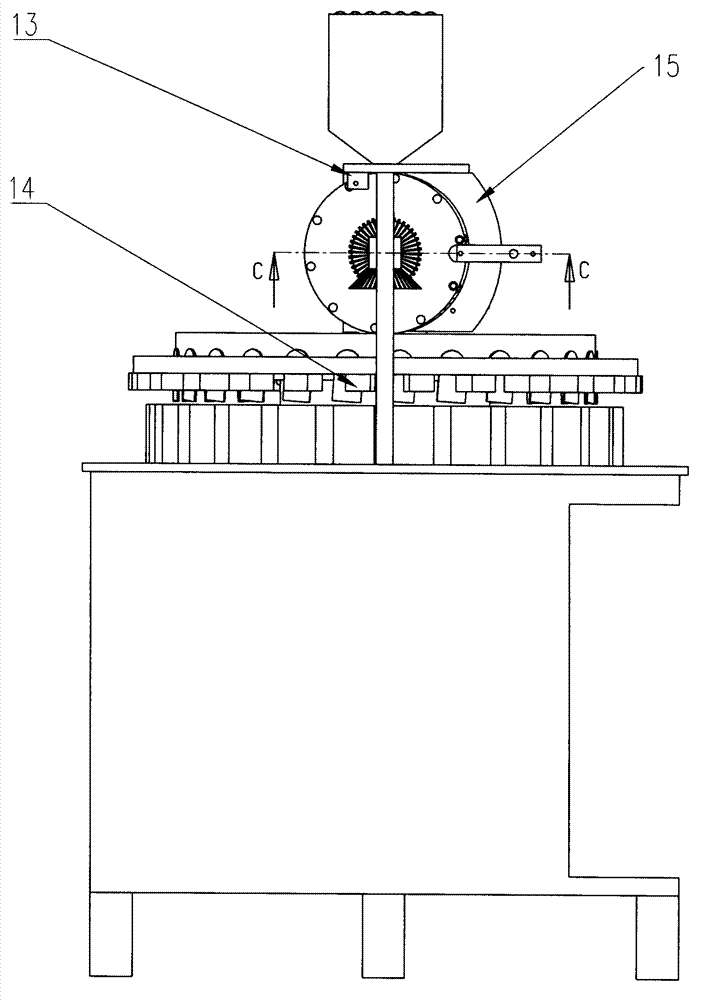

[0032] The present invention is a lithium battery matching machine, such as figure 1 , 2, 3, 4, 5, 10, and 11, a lithium battery matching machine includes a frame (9), the frame (9) is a plate at the top and a bearing seat is left in the center, and the circumferential array on the plate has A plurality of material receiving boxes (12) limit blocks, the lower part of the board is the chassis body, and the chassis body is fixedly equipped with air pressure gauge, power supply, solenoid valve, internal resistance and voltmeter, and control unit. It is characterized in that: on the bracket 1 (8) Bearing seats are left, and the corresponding two sides on the frame (9) plate are respectively fixedly connected with support 1 (8) and support 2 (10), and one end of support 3 (24) is respectively left with bearings on two surfaces perpendicular to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com