Iron core matching method based on electromagnetic induction effect

A technology of electromagnetic induction and iron core, applied in the field of iron core matching based on electromagnetic induction effect, can solve the problems of labor-intensive, time-consuming, unclear judgment, etc., and achieve the advantages of simple matching method, fast matching speed and accurate matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

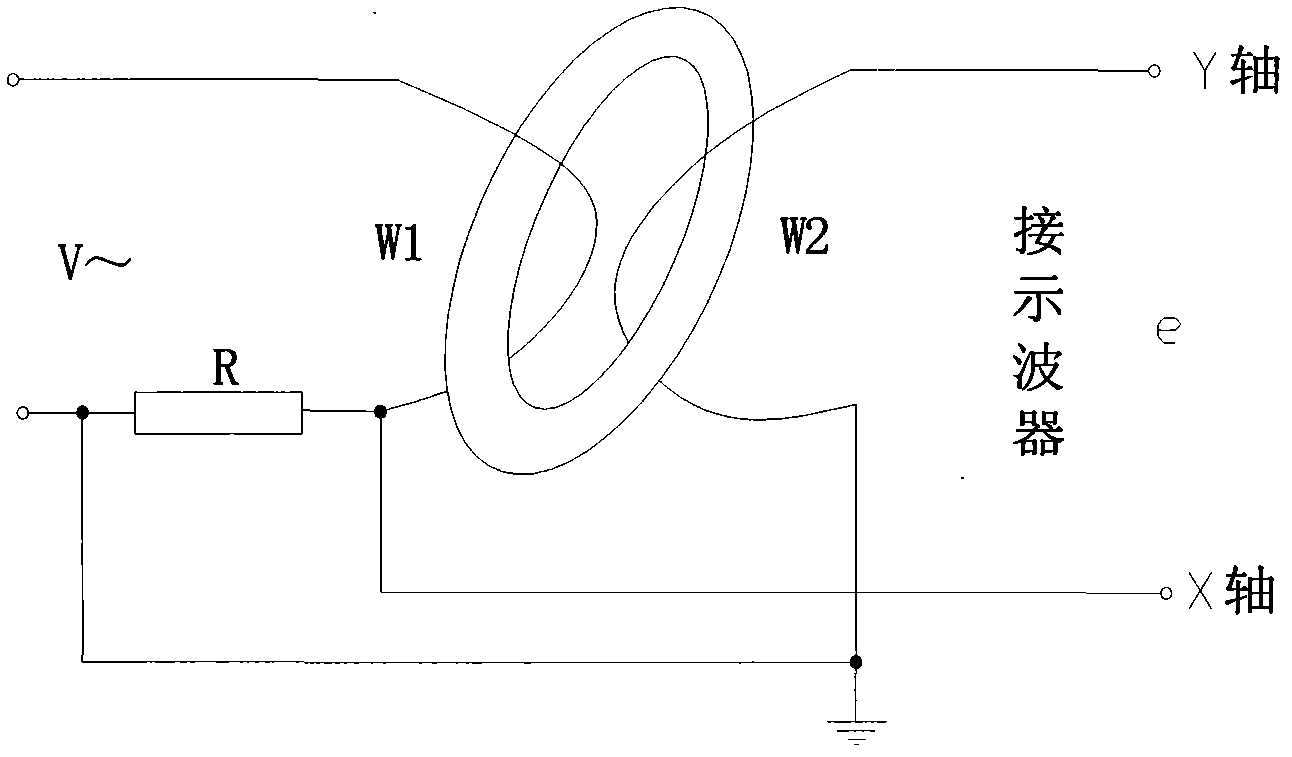

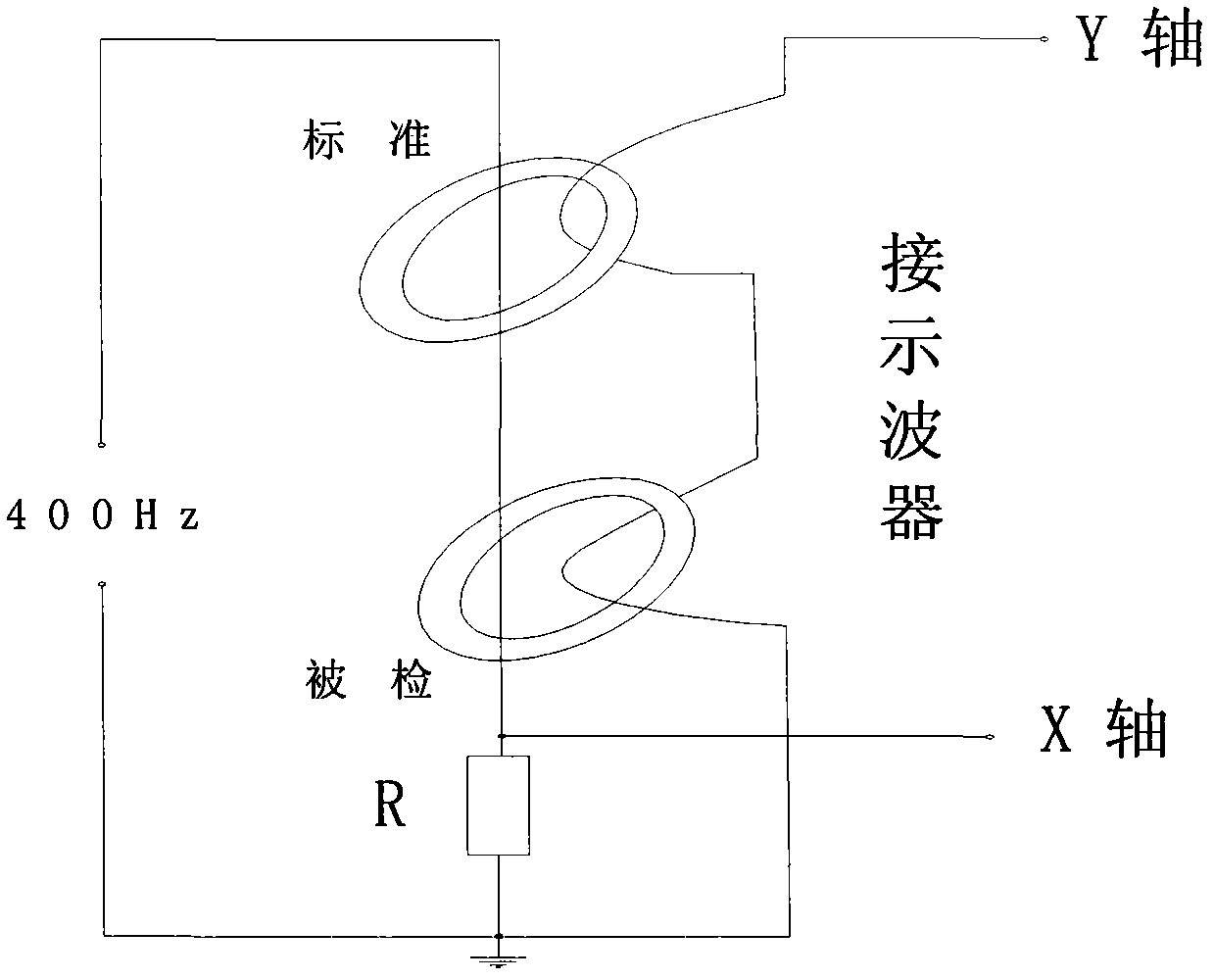

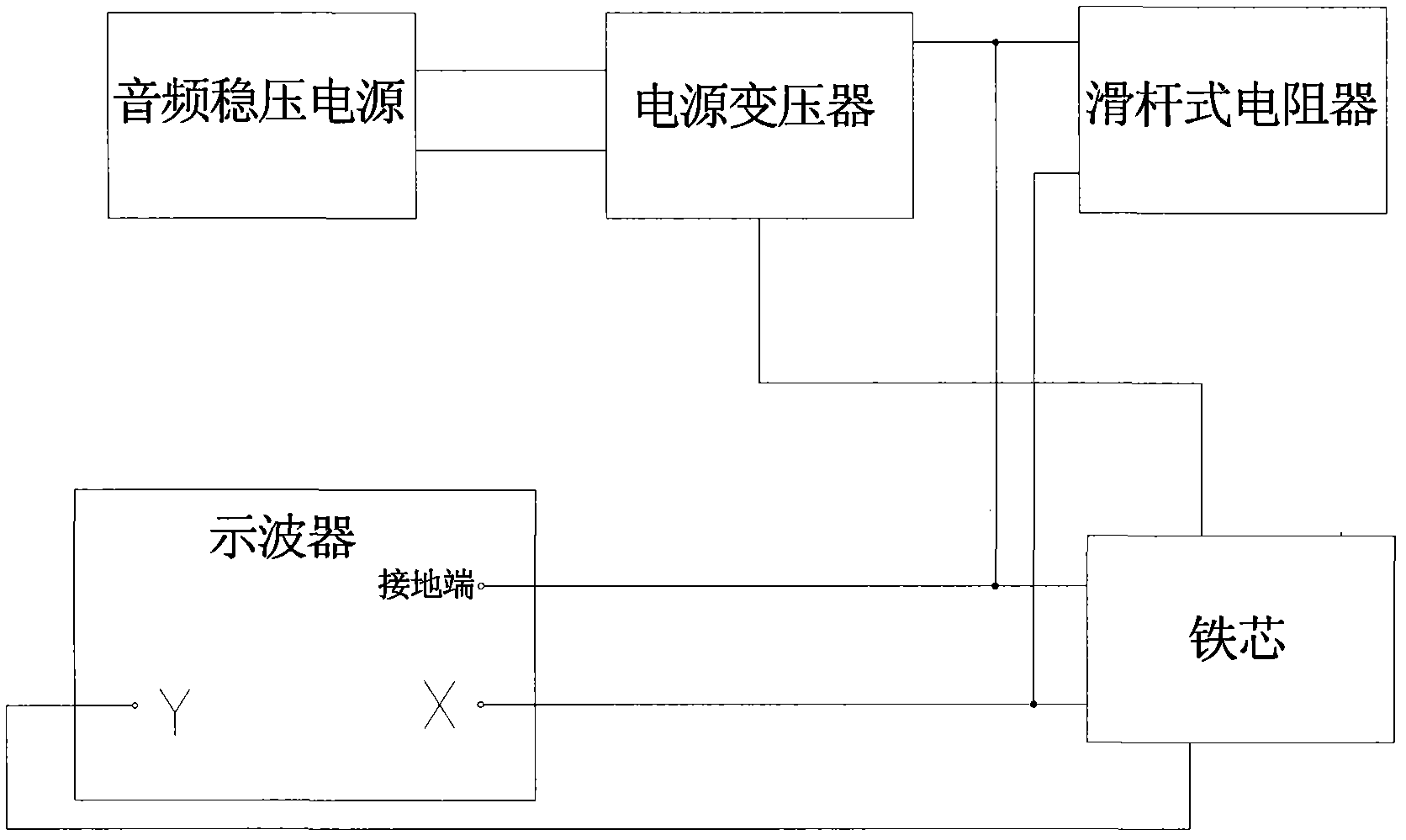

[0012] In the invention, the wires are directly penetrated into the iron cores to select and match the iron cores, and two groups of wires are sequentially passed through a group of iron cores to be selected. Connect test equipment:

[0013] Connect the two output terminals of the audio power supply to the two input terminals of the power transformer, and then connect one output terminal of the power transformer to a group of wires passing through the iron core to be selected, and the other end of the group of wires is connected to the slide Connect the middle end of the rod resistor to the X end of the oscilloscope; connect the other output end of the power transformer to one end of the sliding rod resistor, and at the same time connect this end of the sliding rod resistor to one end of another set of wires, The ground terminal of the oscilloscope is connected, and the other end of the other set of wires is connected to the Y terminal of the oscilloscope.

[0014] Test the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com