Integrated device for slagging, cooling and crushing of titanium slag electric furnace

A technology of crushing device and electric furnace, applied in the field of integrated crushing device, slag removal and cooling of titanium slag electric furnace, can solve the problems of small working space, large number of crushing equipment, large workload, etc., and achieve the effect of ensuring smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

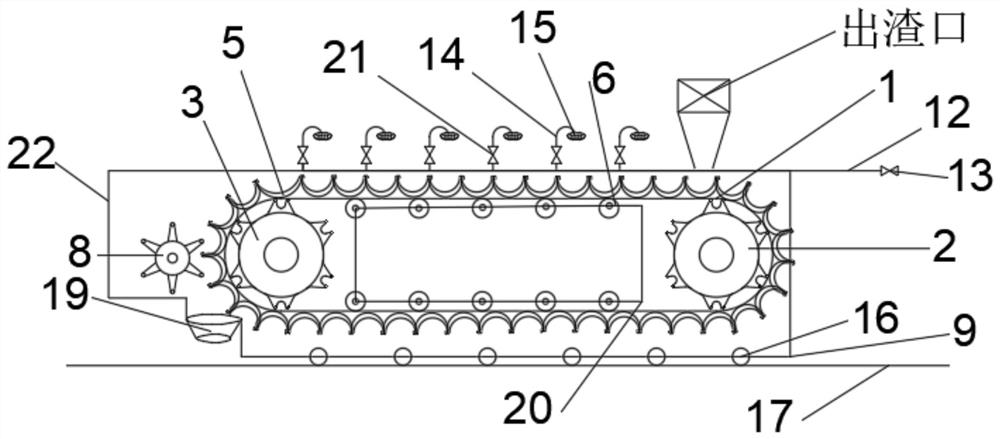

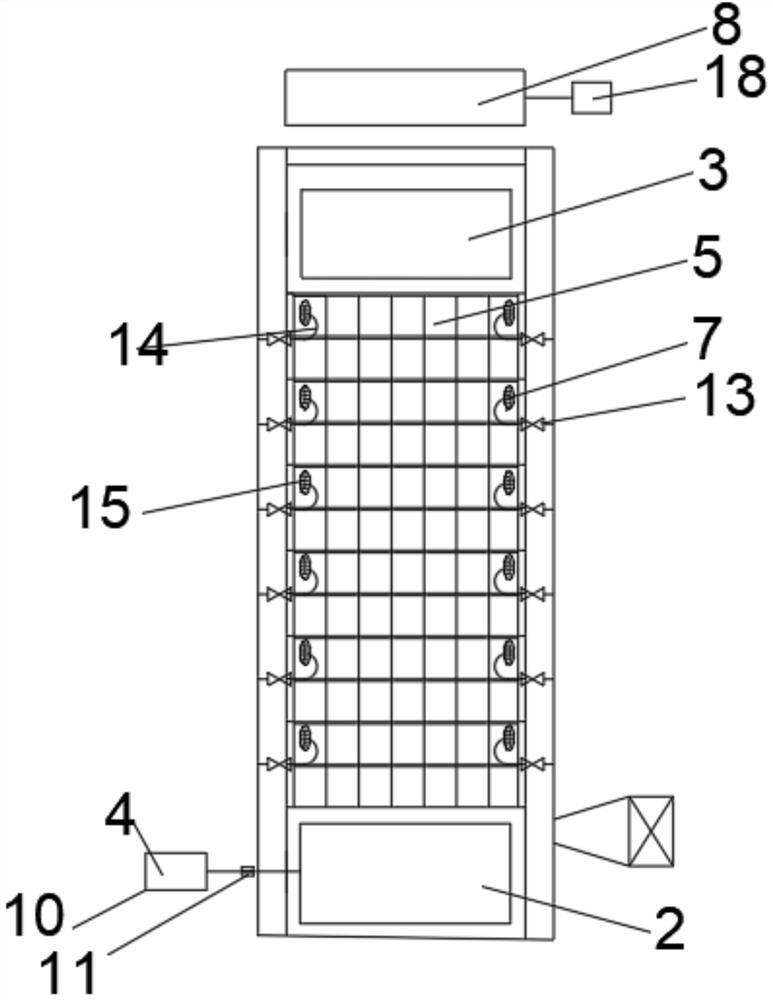

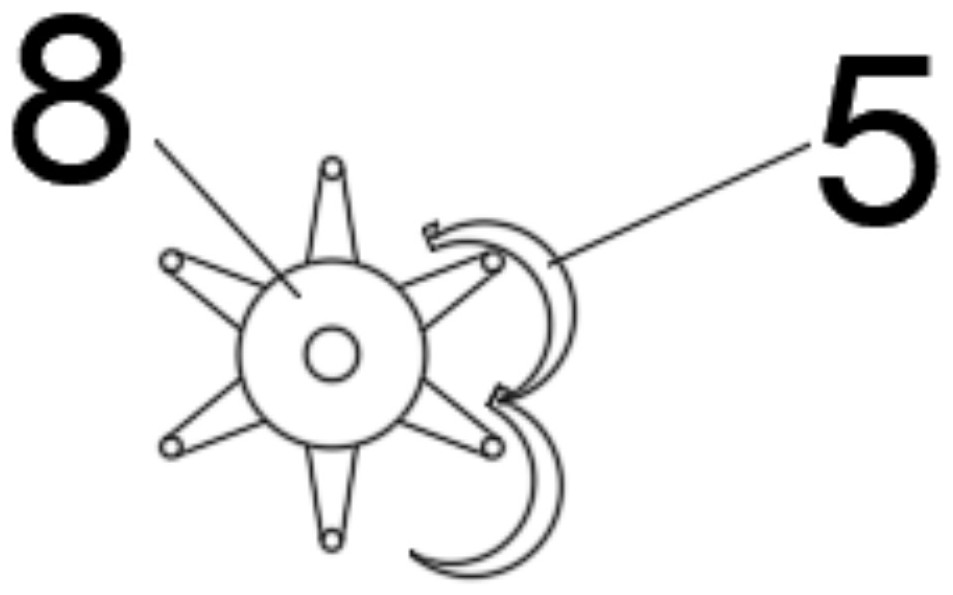

[0027] A device that integrates slag removal, cooling and crushing of titanium slag electric furnace, in order to solve the problem of narrow working space and potential safety hazards in the sand pit slag removal method in the current slag removal, which may cause harm to electric furnace equipment and staff and The way of slag truck slag discharge causes a lot of dust, and the workload is heavy. On the other hand, it needs a lot of crushing equipment, which increases the cost. As a preferred embodiment, such as figure 1 , 2 As shown in , 3, the slag-discharging, cooling and crushing integrated device of titanium slag electric furnace includes conveyor chain belt 1, driving wheel 2, tail wheel 3, power mechanism 4, slag mold 5, supporting roller 6, water spray cooling device 7, The slag removal device 8, the mobile device 9, and the device body 22.

[0028] In this example, the drive wheel 2 is connected to the motor 10 through a coupling 11, and the motor 10 is fixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com