Lever type dynamic pachymeter

A lever type, thickness gauge technology, applied in the field of thickness gauges, can solve the problems of high labor intensity, error, and accuracy decline of inspectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

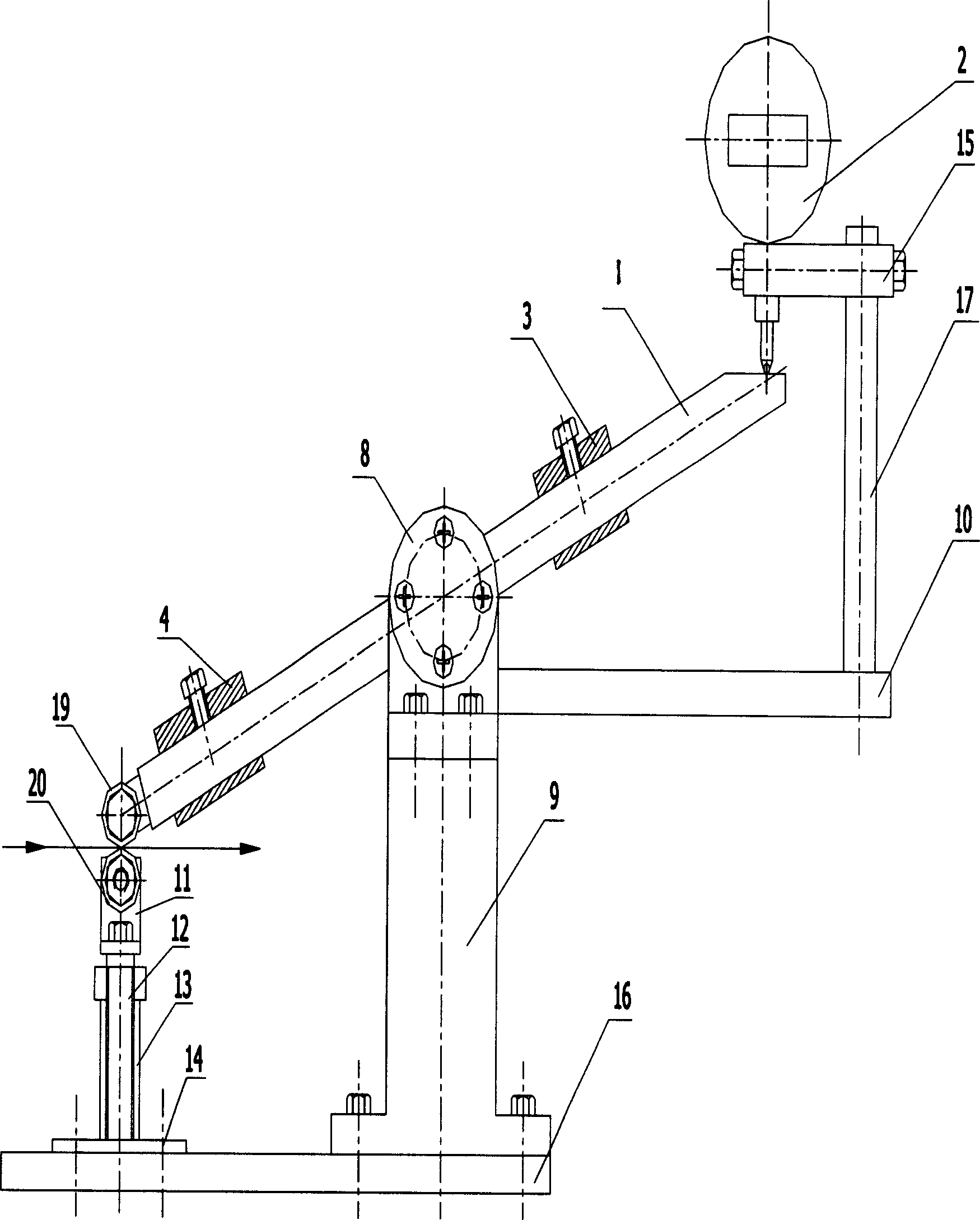

Method used

Image

Examples

Embodiment 1

[0028] A batch of coated negative pole pieces is measured with the lever type dynamic thickness gauge of the present invention.

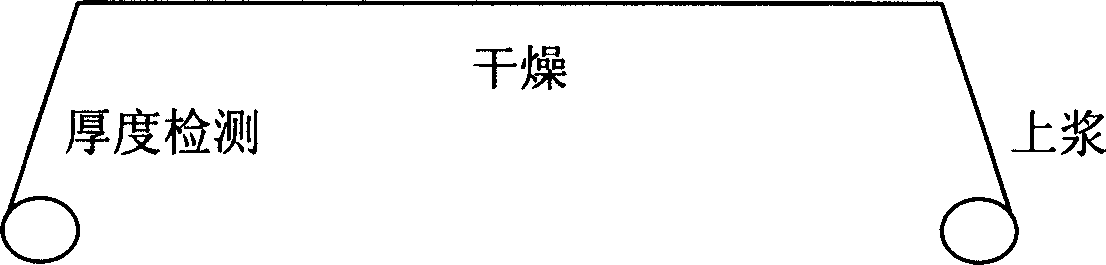

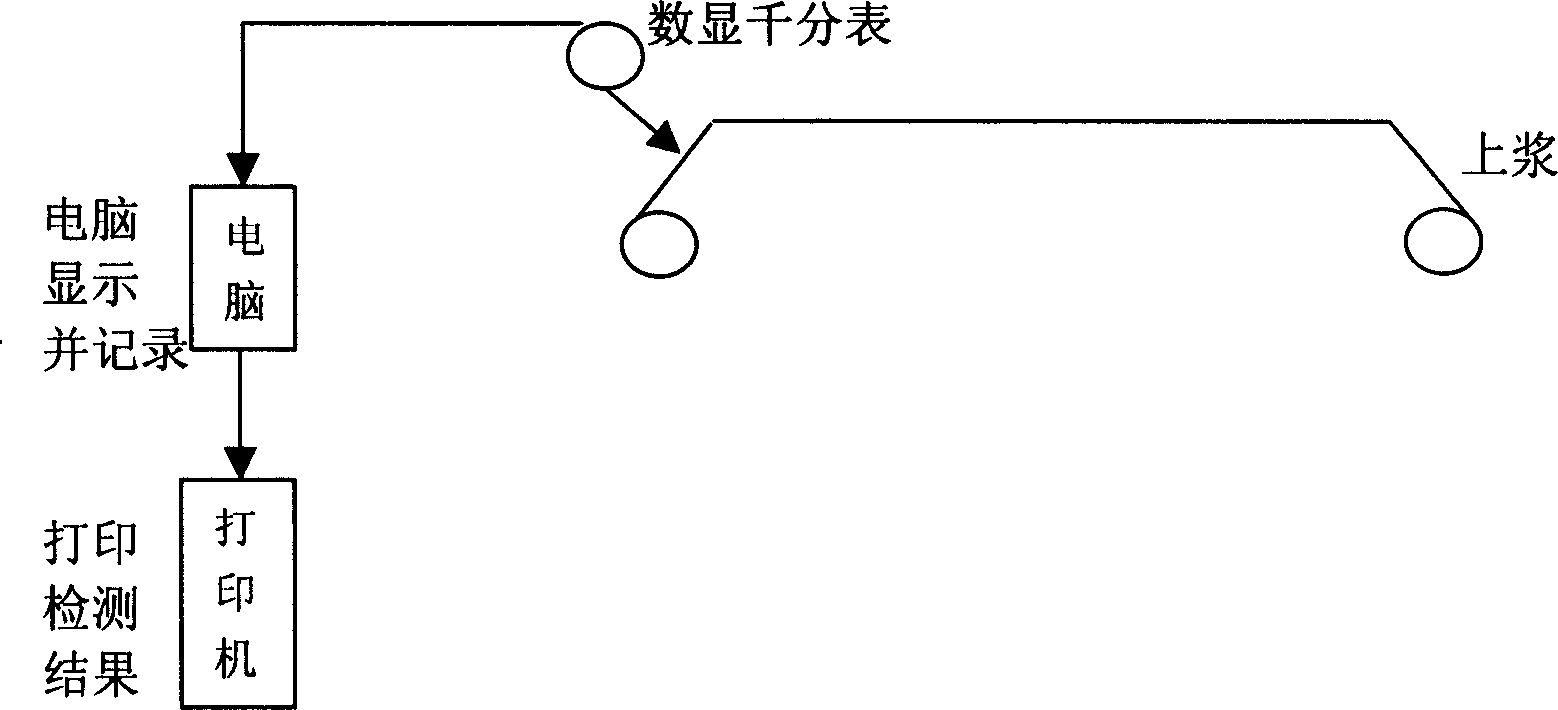

[0029] figure 2 It is a schematic diagram of the battery pole piece coating and thickness detection process of the present invention.

[0030] Copper sheet is used as the negative electrode material, and the thickness is measured after coating the slurry on the coating machine. The thickness requirements are: 110 μm ± 5 μm on one side and 210 μm ± 5 μm on both sides.

[0031] After the double-sided coating and drying process is completed, the pole piece continuously moves through the bearings 19 and 20 of the thickness gauge, and the coating thickness of several points is manually measured with a dial gauge within a certain length, and the digital display is observed at the same time. The reading shown on the meter, if the reading of the digital display dial gauge is inconsistent with the data measured manually, the position of the balance weight ...

Embodiment 2

[0036] Use the lever type dynamic thickness gauge of the present invention to measure the thickness of the double-sided coated positive electrode sheet.

[0037] The positive pole piece is aluminum foil, the coating slurry used is different from that in Example 1, and the hardness of the coated pole piece is smaller than that of the coated pole piece in Example 1. Coating thickness requirements are: 104μm±5μm on one side and 192μm±5μm on both sides.

[0038] The operation sequence is basically the same as in Embodiment 1. The pole piece continuously moves through the bearings 19 and 20 of the thickness gauge, and manually measures the coating thickness of several points with a dial gauge within a certain length, and at the same time observes the readings displayed by the digital display dial gauge. The reading of table is inconsistent with the data of manual measurement, then need to adjust the position of balance weight 4, at this moment, the hardness of the post-coating pol...

Embodiment 3

[0043] Use the lever type dynamic thickness gauge of the present invention to measure the thickness of the negative electrode after the rollers are aligned. The thickness is required to be 140 μm-145 μm, and the operation steps and sequence are the same as those in Examples 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com