Clamping equipment for part machining

A clamping equipment and parts processing technology, which is applied in the field of parts clamping, can solve the problems of steel pipe deformation and damage, large pre-tightening force of steel pipe, loose steel pipe processing, etc., and achieve accurate measurement results, stable steel pipe processing, and reduce distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is further described in detail through specific implementation methods:

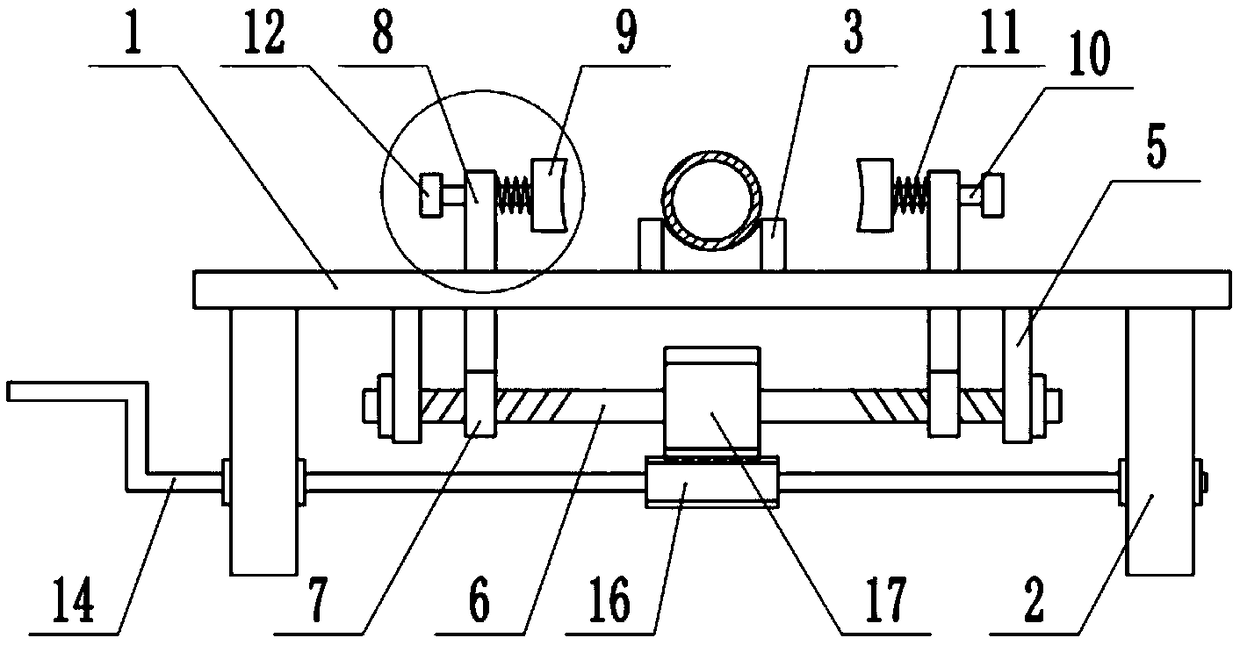

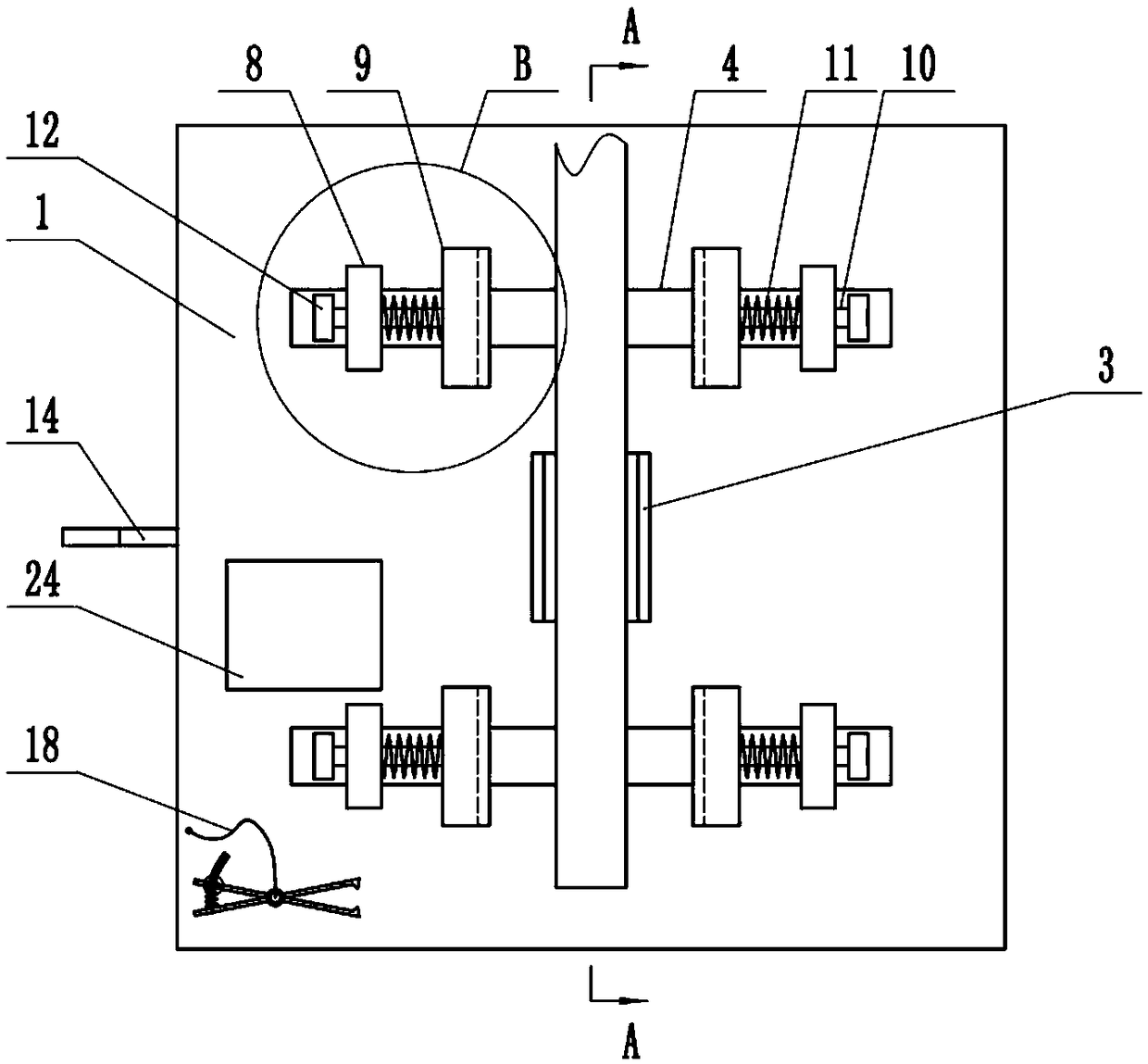

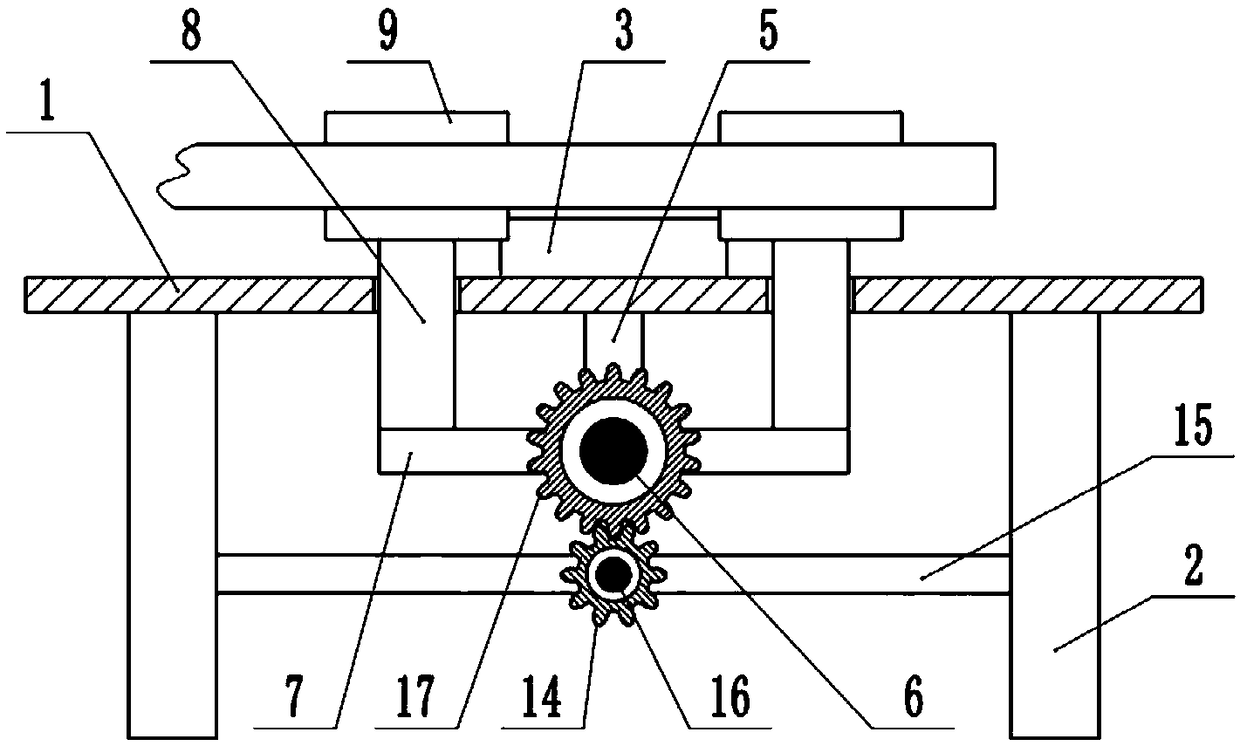

[0037]The reference signs in the drawings of the description include: fixed platform 1, outrigger 2, support seat 3, chute 4, fixed seat 5, two-way screw rod 6, slide plate 7, slider 8, fixed block 9, slide rod 10, Compression spring 11, limit block 12, milling plane 13, manual rocker 14, fixed plate 15, first spur gear 16, second spur gear 17, elastic rope 18, first measuring rod 19, second measuring rod 20, Back-moving spring 21, measuring ruler 22, observation slot 23, signboard 24.

[0038] The embodiment is basically as attached figure 1 Shown: clamping equipment for parts processing, including a fixed platform 1 set horizontally, four corners of the bottom of the fixed platform 1 are provided with outriggers 2, and the upper end of the fixed platform 1 is provided with a support seat 3 for initially placing steel pipes, and the support seat 3 There is an arc-shaped groove on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com