Simple measuring device capable of accurately measuring slab thickness of floor slab

A technology of precise measurement and measuring instruments, which is applied in the field of measuring instruments, can solve the problems of low accuracy, increase the length and weight of vertical rods, and the inaccurate measurement of scale rods, so as to achieve the effect of high practicality and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

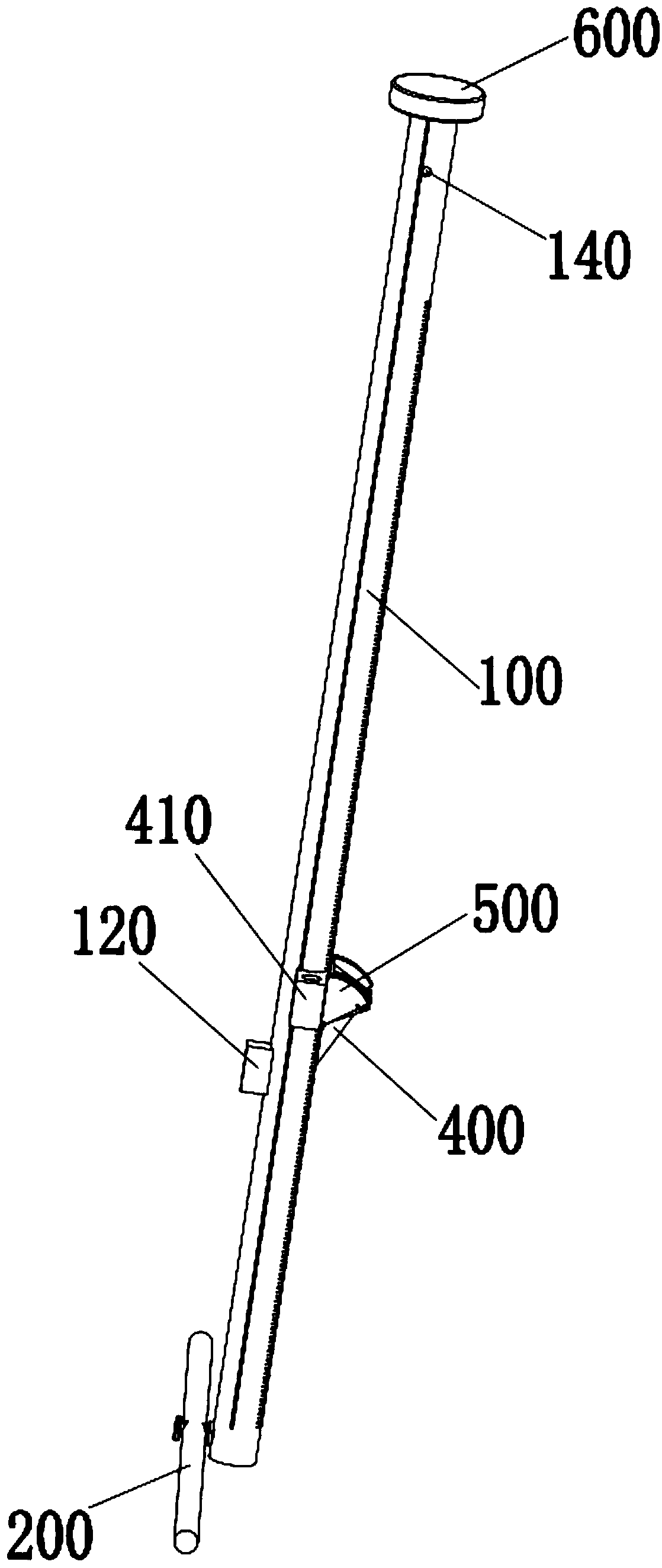

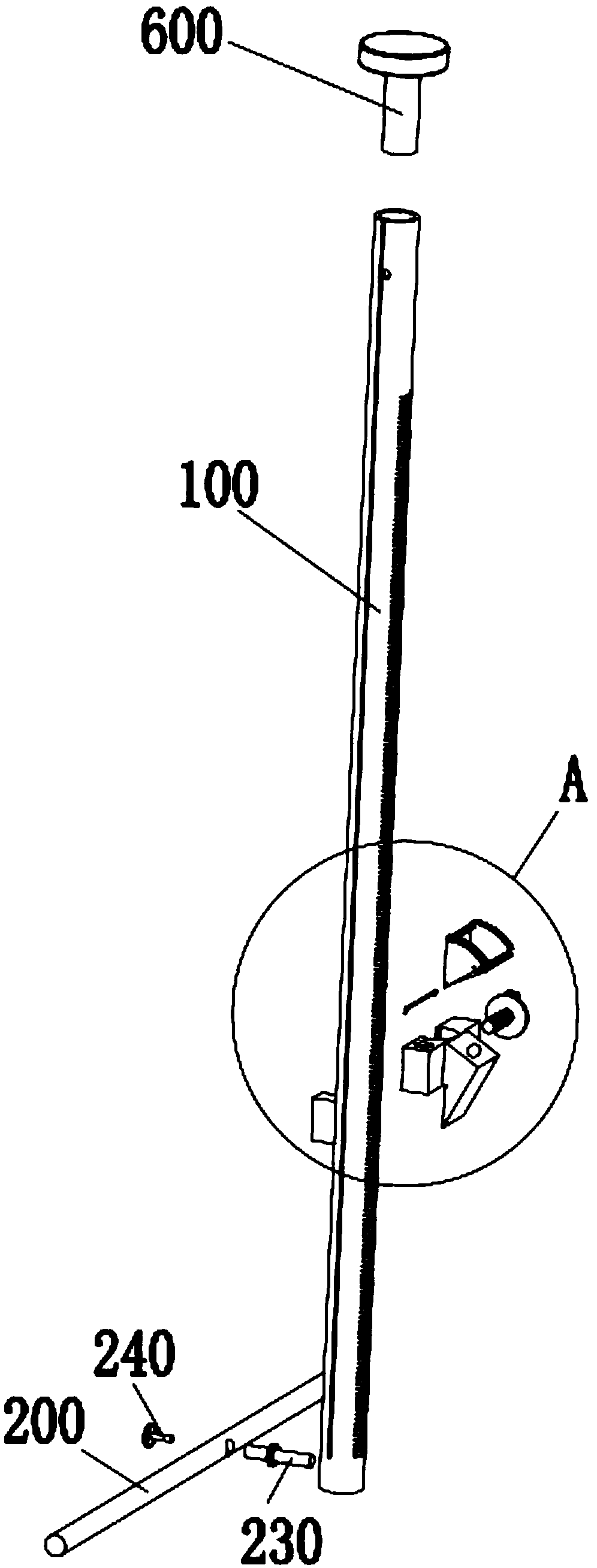

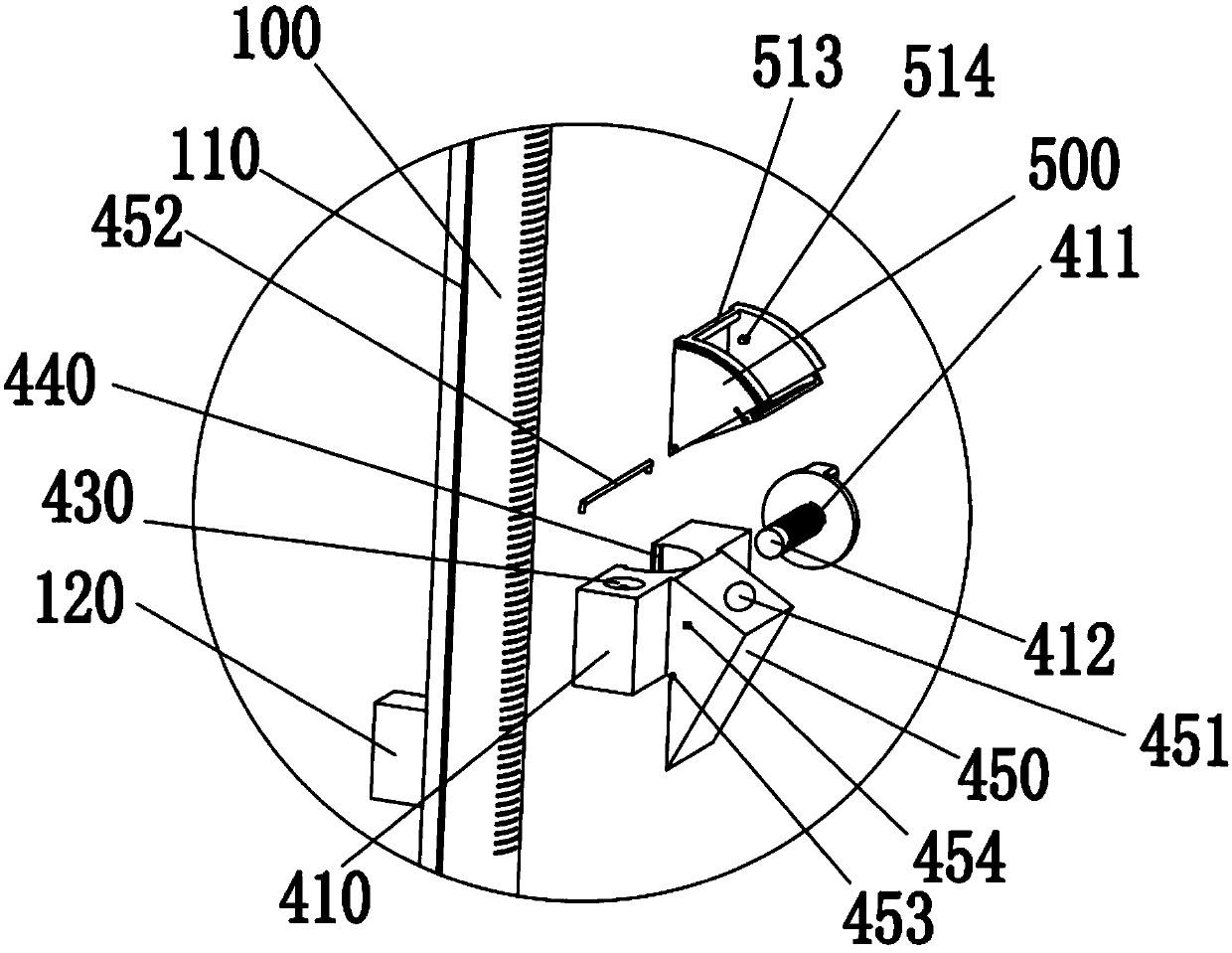

[0045] Such as Figure 1-Figure 14 As shown, a simple measuring device for accurately measuring the thickness of floor slabs includes a vertical rod 100 with a scale mark and a rotating rod 200 for blocking the bottom of the floor 300. The rotating rod 200 is hinged at the bottom end of the vertical rod 100. When When the rotating rod 200 is connected to the bottom of the floor 300, the horizontal plane of the connection is aligned with the zero scale on the vertical rod 100, including the sliding rule 400, which is socketed outside the vertical rod 100 and can reciprocate along the vertical rod 100 Movement, the two sides of the sliding rule 400 have a blocking part 410 that blocks the surface of the floor 300, and the sliding rule 400 has a viewing window 420 for viewing the scale reading of the vertical rod 100, and the top surface of the blocking part 410 is perpendicular to the vertical rod 100 Moreover, a first universal spirit level 430 for measuring the horizontal dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com