Supporting structure of extra-large cross-section loess tunnel and construction method thereof

A technology for loess tunnels and extra-large cross-sections, applied in the field of tunnels, which can solve problems such as narrow construction space, numerous construction steps, and slow construction progress, and achieve the effects of simple construction procedures, convenient large-scale mechanical operations, and large excavation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

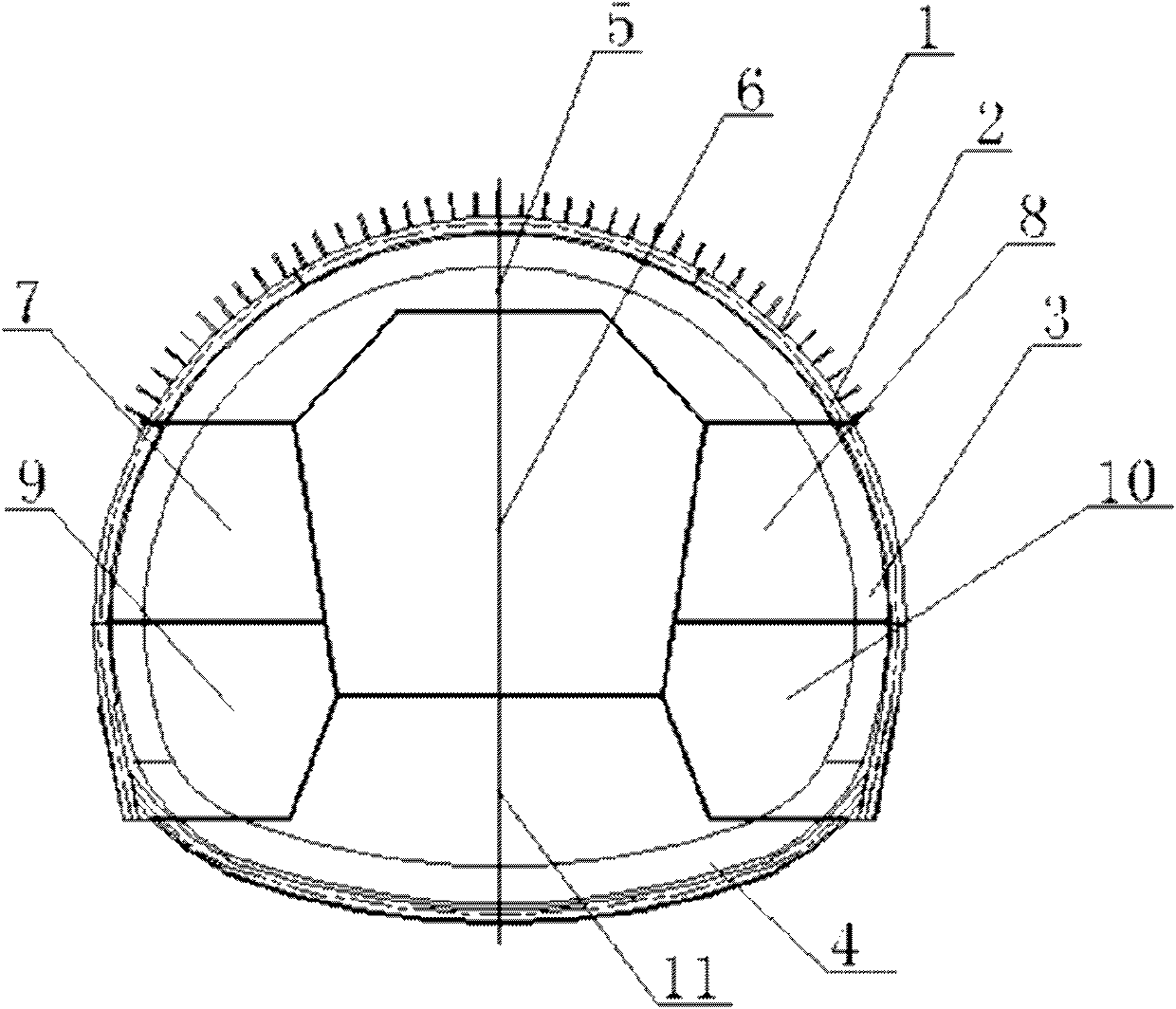

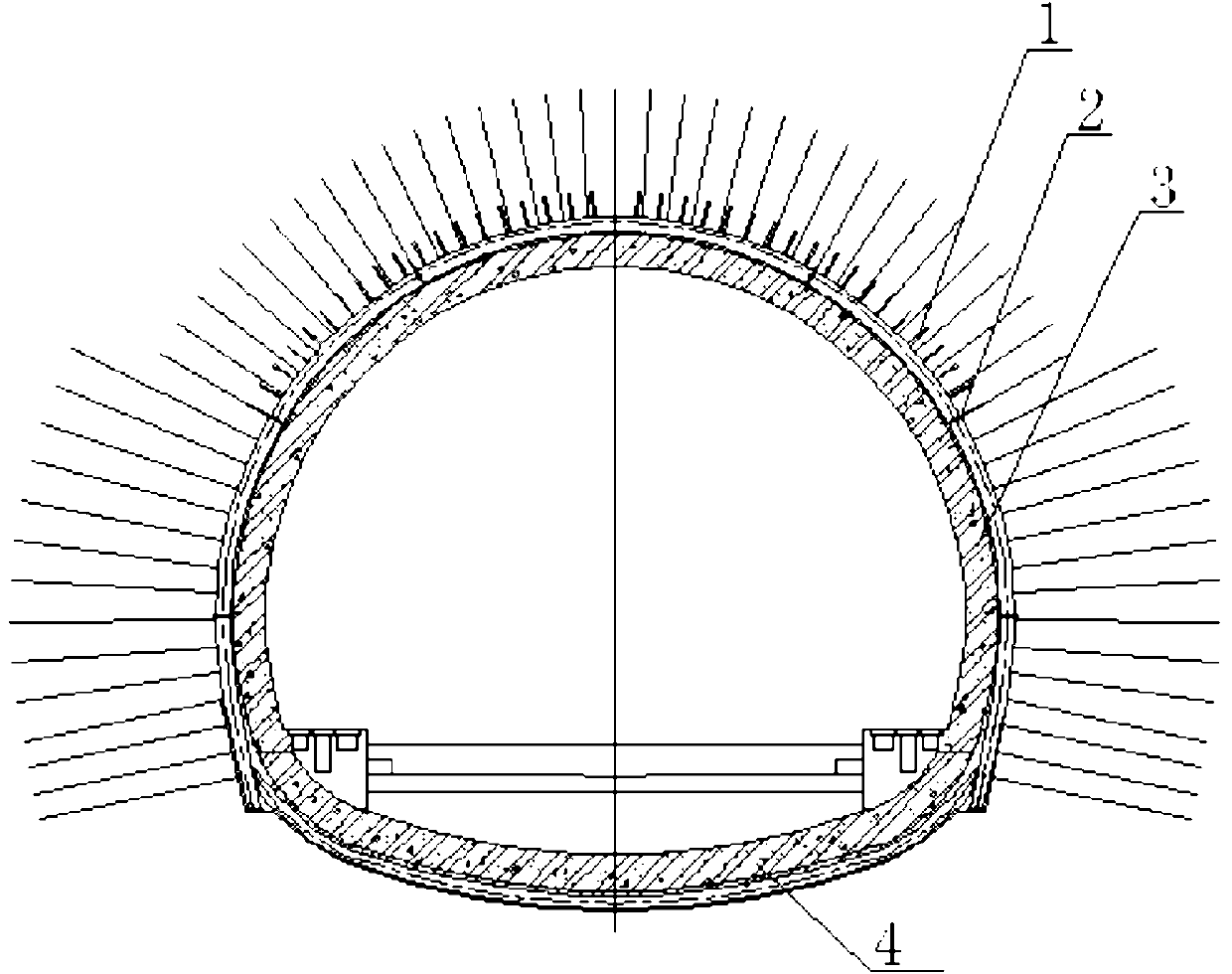

[0024] see figure 1 , the present invention includes initial support 2, secondary lining 3 of the arch wall, and inverted arch 4, and a small conduit advance support 1 is arranged along the contour line of the arch of the tunnel, and is arranged between the initial support 2 and the secondary lining 3 of the arch wall There is a waterproof layer.

[0025] The initial support 2 is composed of shotcrete, erected steel frame, installed anchor rods and hung steel mesh.

[0026] The inverted arch part of primary support 2 includes shotcrete and erected steel frame.

[0027] The waterproof layer is made of non-woven fabric and waterproof board.

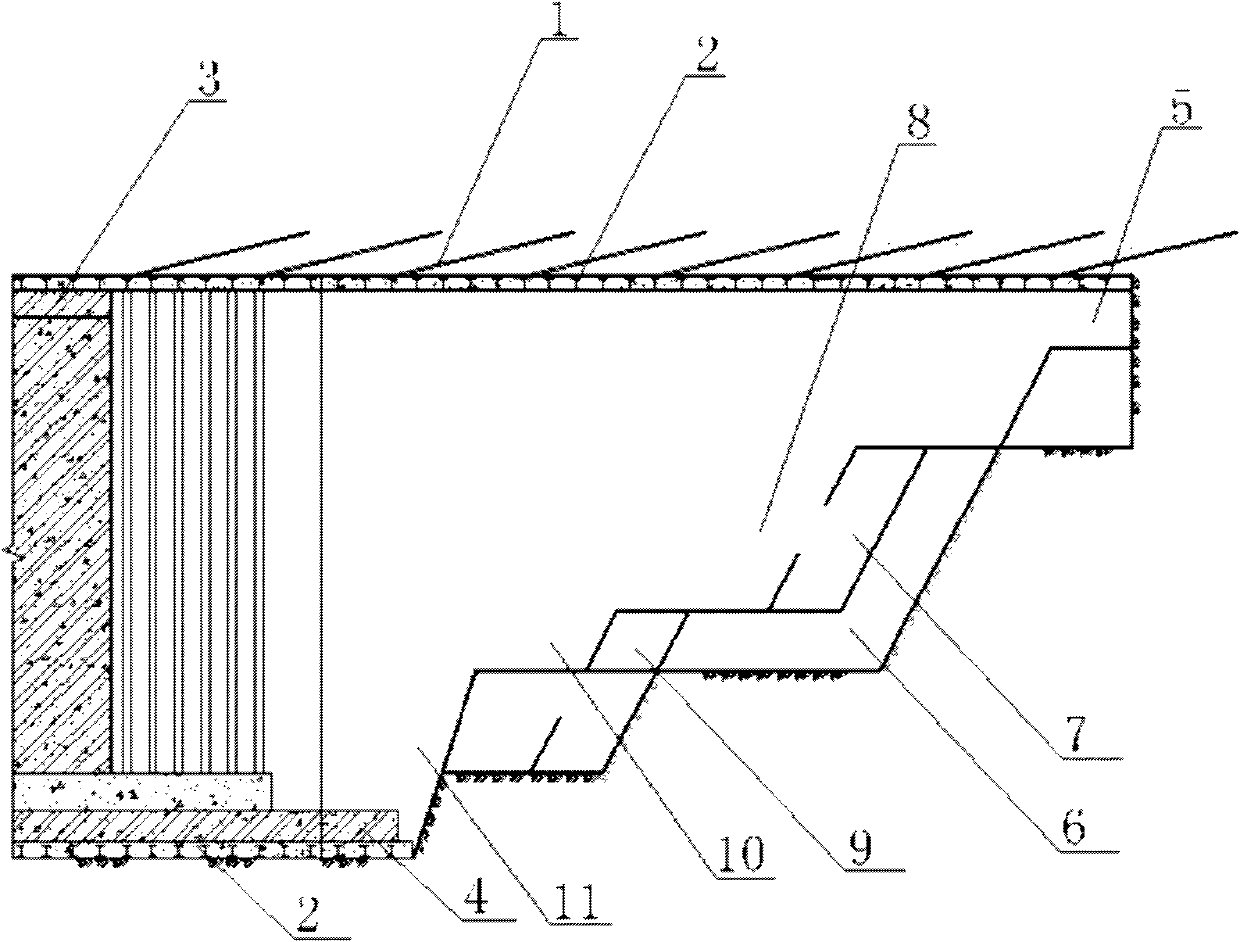

[0028] see figure 2 , 3 , the steps of implementing the construction method of the present invention are:

[0029] (1), along the excavation contour line of the tunnel arch, perform small conduit ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com