Drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device and using method thereof

A discharge device and coal seam technology, applied in the direction of safety devices, drainage, gas discharge, etc., can solve the problems of unable to discharge gas in time, manually clean up cinders, and poor working environment, so as to prevent pollution of the working surface environment, avoid damage to the working environment, Avoid the effects of blind work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

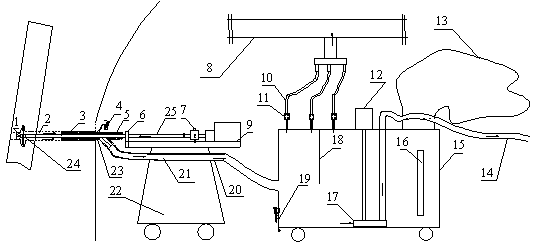

[0026] The present invention will be further described below by specific examples. The specific implementation process is as follows:

[0027] Connect and assemble the whole set of devices according to the following methods,

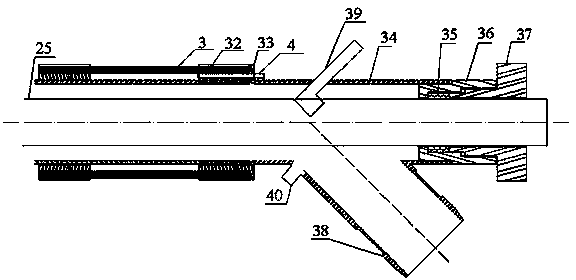

[0028] First, drill 1~2m normally, withdraw the drill bit 1 and the drill pipe (25), install the water jet high and low pressure switching device 24 between the drill bit 1 and the drill pipe 25, and then remove the drill pipe 25 with the drill bit 1 from the Insert the front end of the spray hole deflector 23, put the spray hole deflector 23 together with the drill pipe 25 with the drill bit 1 into the drill hole 2;

[0029] Then, all the capsules 3 on the anti-blowout hole guide device 23 are inserted into the borehole, water (air) is injected from the water (air) pipe 4, and the pressure stops when the pressure reaches 2MPa, and the expansion of the capsule 3 is in close contact with the wall of the borehole 2 , then adjust the drill pipe sealing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com