Assembly type utility tunnel for building envelop bearing strength and construction method thereof

A technology of enclosure structure and integrated pipe gallery, which is applied in infrastructure engineering, protection devices, underwater structures, etc. It has the advantages of convenient hoisting, improving economic efficiency and reducing the construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited thereto.

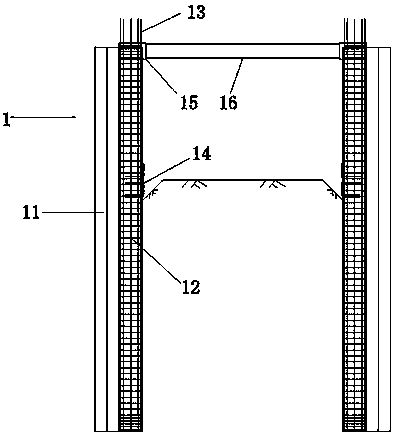

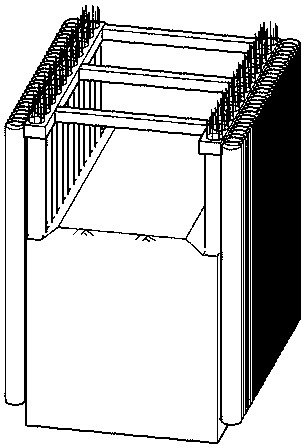

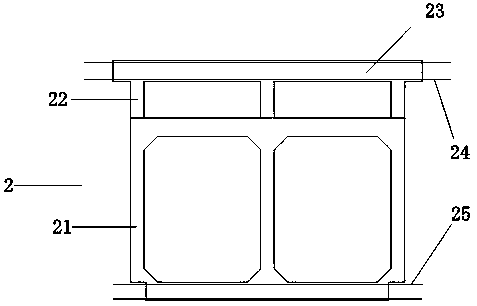

[0040] The prefabricated integrated pipe gallery provided by this example is bearing the load of the enclosure structure, such as Figure 1-8As shown, the prefabricated integrated pipe gallery of the present invention is composed of two parts of the envelope structure 1 and the prefabricated integrated pipe gallery 2. The envelope structure 1 includes a three-axis cement-soil mixing pile 11, a drill Cast-in-place pile 12, pile top reserved reinforcement 13, pre-embedded reinforcement 14, top pressure beam 15, internal support 16; prefabricated integrated pipe gallery 2 includes pipe gallery entity 21, structural beam 22, lap joint plate 23, and reserved rib for lap joint plate 24 ribs 25 are reserved for the bottom plate.

[0041] Such as figure 1 and figure 2 As shown, the en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com