Fabricated integral-type revetment structure on soft soil foundation and construction method thereof

A soft soil foundation and integrated technology, applied in the direction of pier, quay wall, embankment, etc., can solve the problems of large site operations, waste of building materials, and a large number of formwork, etc., to achieve less waste of resources, safe and stable structures, and tight construction schedules Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

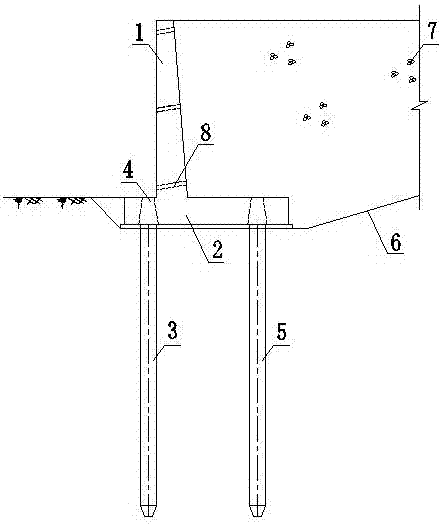

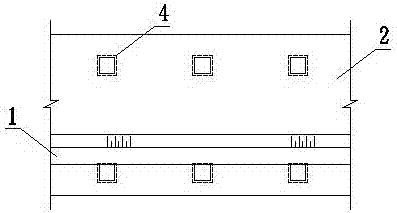

[0027] Such as figure 1 and figure 2 As shown, an assembled integrated revetment structure on a soft soil foundation includes a prefabricated vertical plate 1, a prefabricated bottom plate 2 and a prefabricated pile foundation 3; the top of the prefabricated bottom plate 2 is provided with a prefabricated vertical plate 1, and the bottom The end is provided with a prefabricated pile foundation 3; the prefabricated vertical plate 1 and the prefabricated bottom plate 2 are combined into an integrated prefabricated L-shaped retaining wall, and the prefabricated vertical plate 1 and the prefabricated bottom plate 2 are poured in one piece; the prefabricated pile foundation 3 includes several root prefabricated piles 5; the top of each prefabricated pile 5 extends into the prefabricated bottom plate 2; the prefabricated bottom plate 2 is uniformly provided with several prefabricated pile pile holes 4, and each prefabricated pile pile hole 4 corresponds to the prefabricated pile 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com