Wood formwork early-dismantling supporting device and construction application method

A supporting device and wooden formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of limiting formwork turnover rate, inability to dismantle in blocks, occupying formwork, etc., and achieve saving The effect of a large number of templates, improving labor productivity, and increasing the turnover rate of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

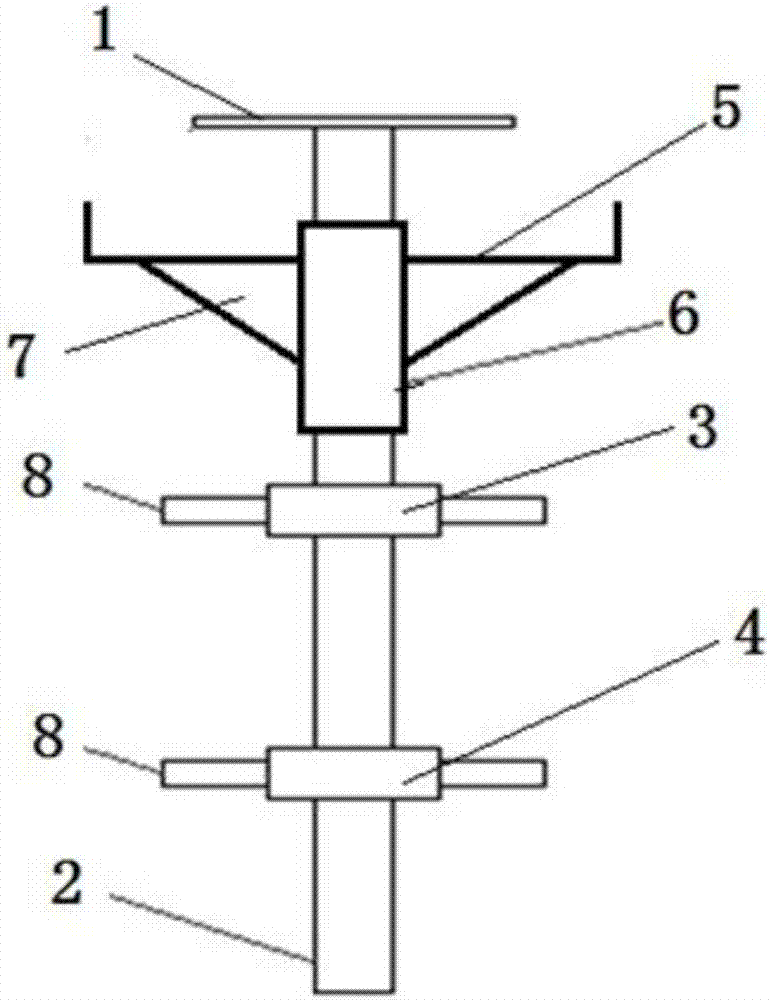

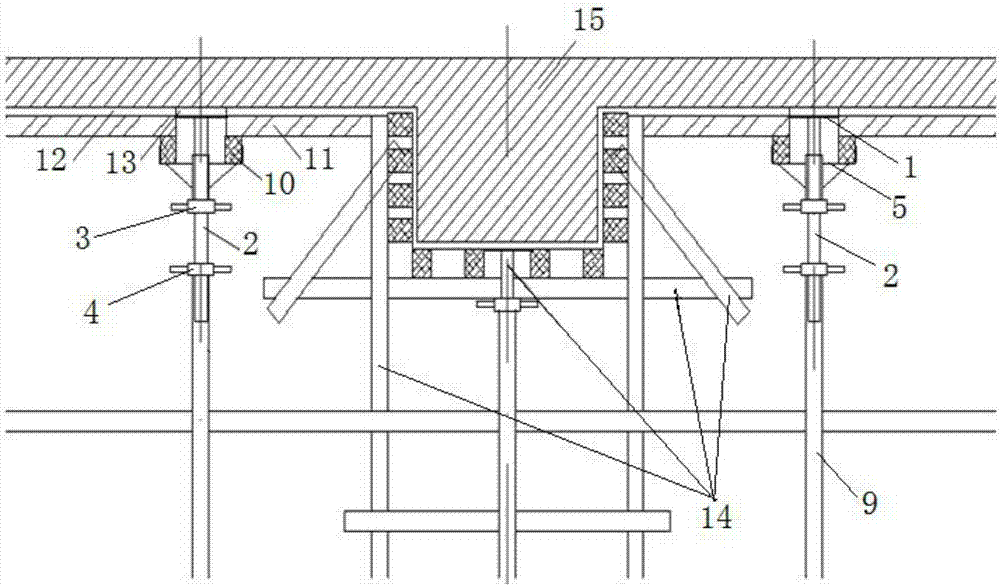

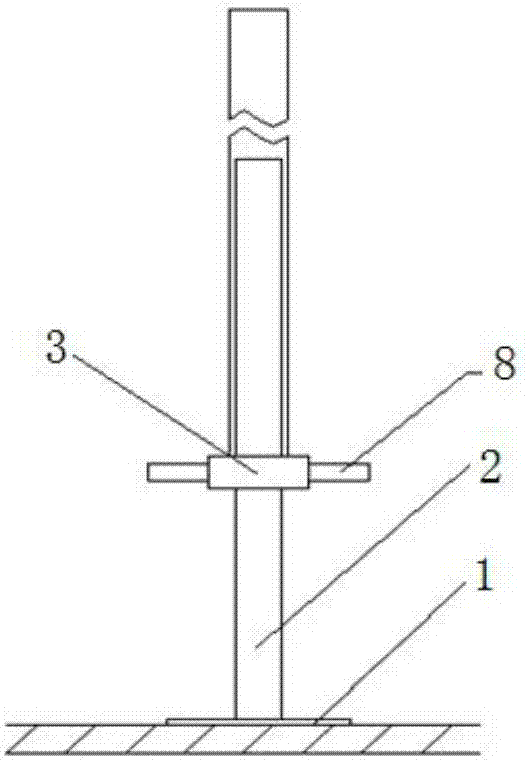

[0017] figure 1 As shown, the support device for early removal of wooden formwork of the present invention includes a jacking part and an adjustable supporting plate part; 3 and the lower adjusting nut 4 are formed, and handles 8 are respectively welded on both sides of the upper adjusting nut and the lower adjusting nut. The adjustable pallet part is composed of a pallet 5 and a steel sleeve 6 passing through the center of the pallet; A reinforcing rib plate 7 is welded between the bottom of the tray 5 and the outside of the steel casing 6 .

[0018] In this embodiment, the screw rod 2 is 500 mm long and 38 mm in diameter. The steel top plate 1 is a square of 150 mm×150 mm, and the top of the screw rod is welded to the center of the steel top plate. The tray 5 is a rectangular plate stamped from a steel plate of 330mm×150mm, and the edge of the plate is 40mm higher than the surface of the plate. The top of the steel casing is 20mm higher than the flange. The reinforcing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com