Split mounting type bridge wet joint construction method

A construction method and wet joint technology are applied in the construction field of wet joint construction of high pier assembled bridges, which can solve the problems of small operation space, unfavorable construction, cumbersome transportation of formwork installation or disassembly, etc. The effect of easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A construction method for wet joints of assembled bridges, comprising the following steps:

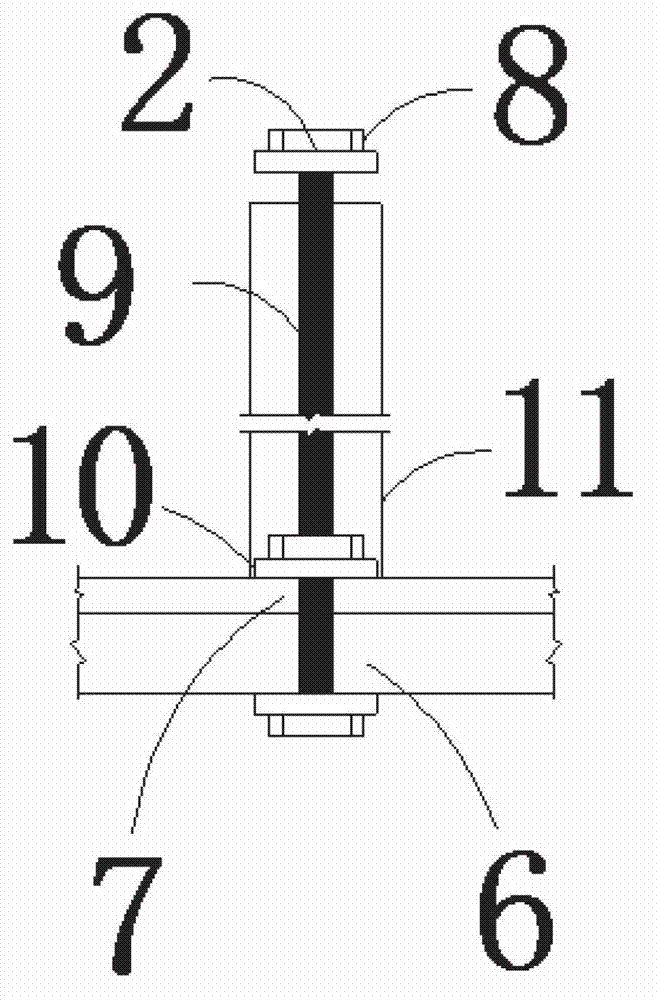

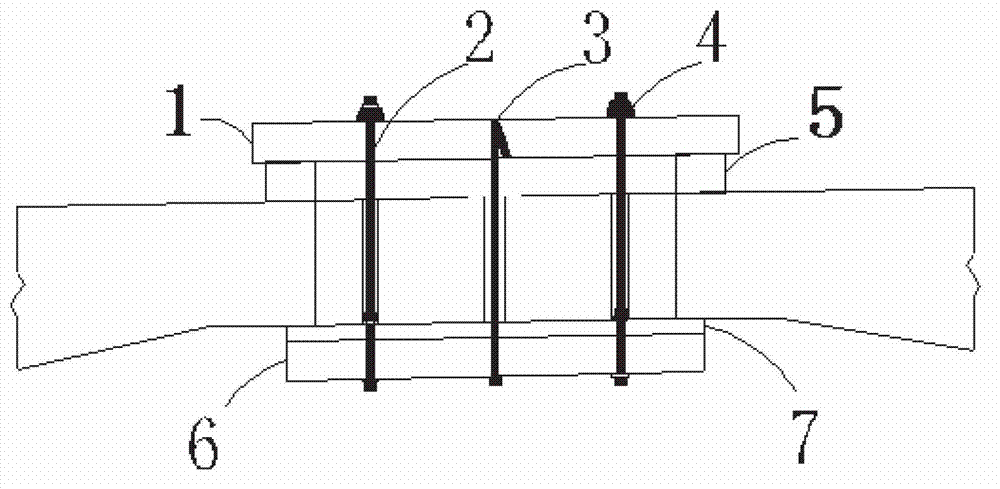

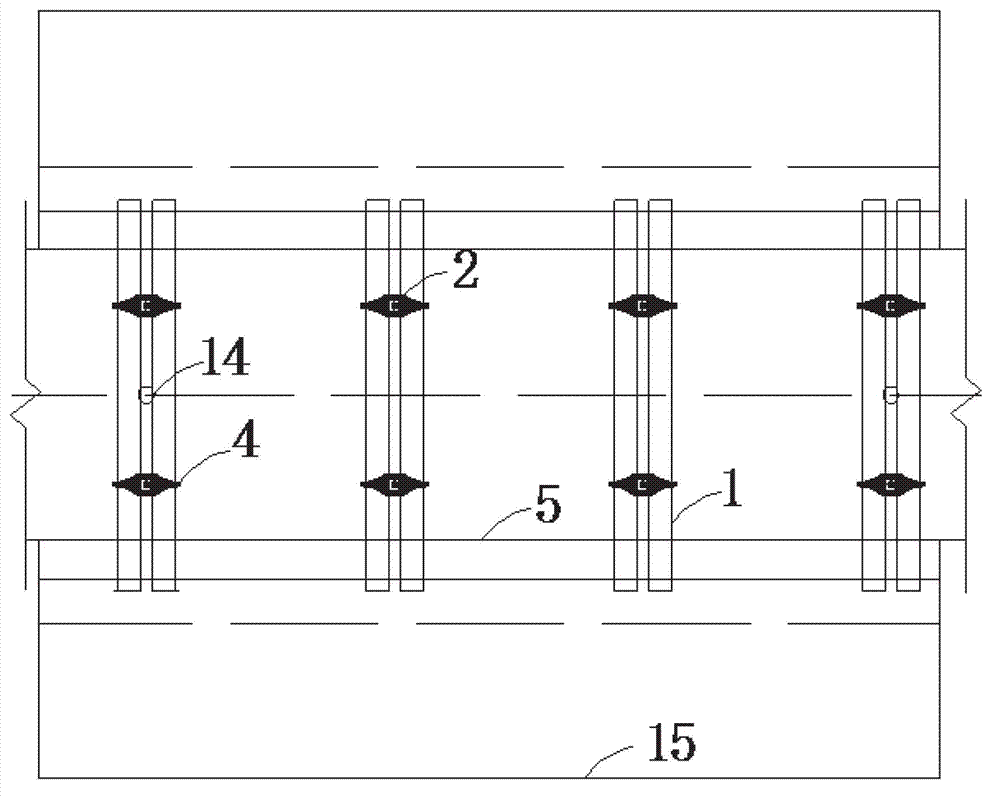

[0024] a. The template 7 and the tie rod 2 are fixed, and the small hoist is used to lift and lower, and the template installation and hanging holes are reserved to realize the smooth lifting and installation of the template, and the removal and hanging of the template. First, drill the template and the square timber under the template , and then fix the formwork and tie rods firmly; finally, tie the slings to the formwork and the steel wires through which the square timber drill holes pass, and then lift the formwork system for installation;

[0025] b. Lift the formwork system into place, then use the steel pipe as a "bridge", use the butterfly buckle together, and use the nut 8 and the gasket 10 to tighten the tie rod 2 and the steel pipe to form a stable system with the square wood on the T beam;

[0026] c. When pouring concrete, pay attention to the pre-embedded PVC pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com