Massive construction system using rock masonry

a construction system and rock masonry technology, applied in the direction of parkings, building types, constructions, etc., can solve the problems of affecting affecting the safety of workers, so as to improve the social environment of workers, improve the effect of speed and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] To facilitate the understanding of the drawings and / or written descriptions, a key number is listed below:

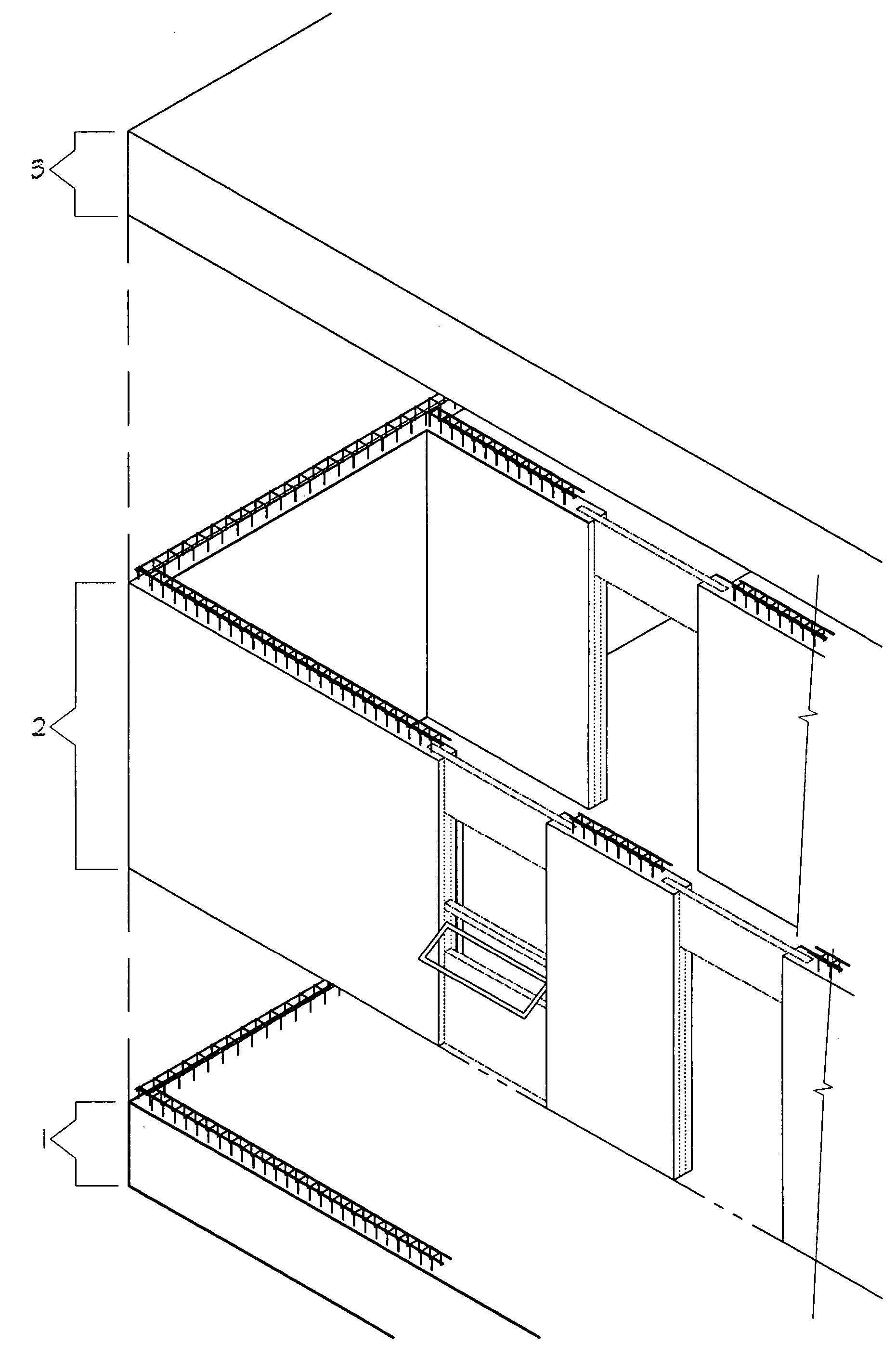

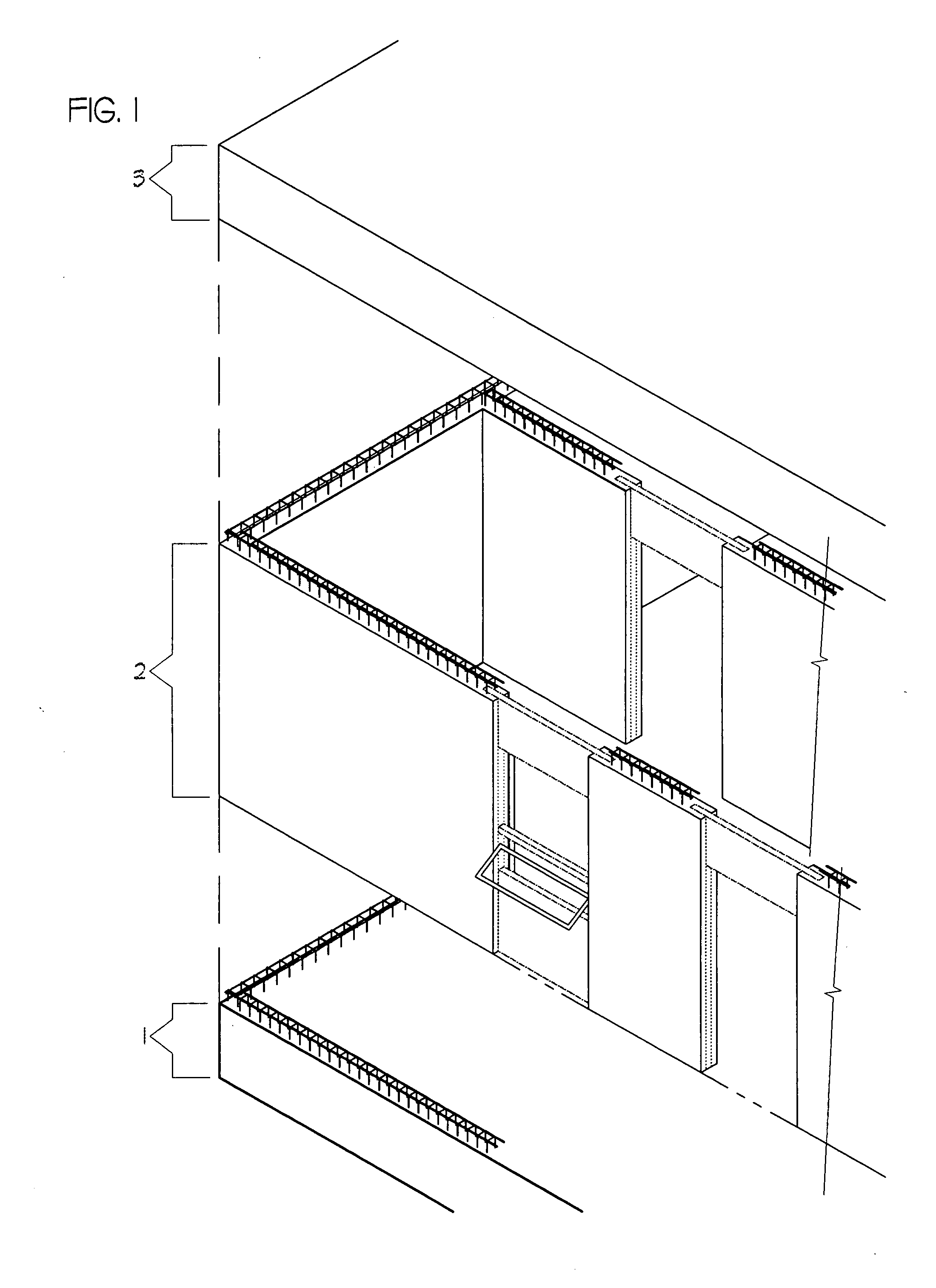

[0060] 1. Foundation [0061] This includes: footings with a shape, where the base is big enough to distribute the imposed loads of walls and roofs to the ground. A floor slab shall be of concrete 18 for floor finishes. An anchor structure 6 a device half embedded where concrete masonry walls shall be set, of the present invention, to connect said footings with the walls.

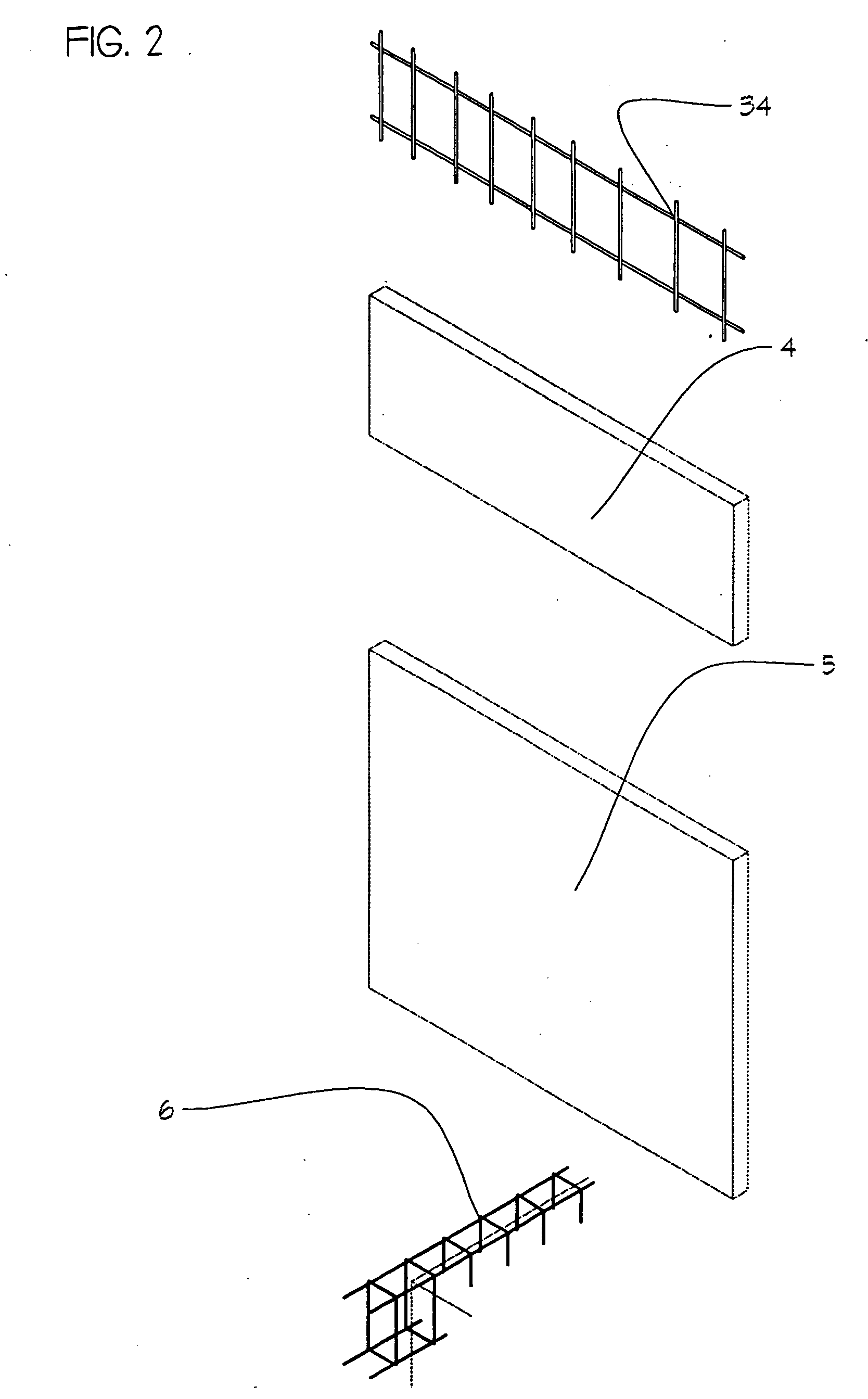

[0062] 2. Concrete Masonry Walls [0063] Walls are elements to enclose spaces from the weather, noise, etc. plus providing privacy. Walls definition includes openings: doors and windows. In the present invention solid walls are built with a concrete masonry 17+18, and the openings use precast headers 4 and precast sills 5, whilst windows frames, and doors frames, and leafs can be of any material, brand or manufactured in construction site. The present invention denotes the molds modifications to make use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com