Method for building railway bridge and simple support T beam bridge

A railway bridge and simply supported technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as unsatisfactory, cumbersome horizontal connection process, and restricted beam erection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

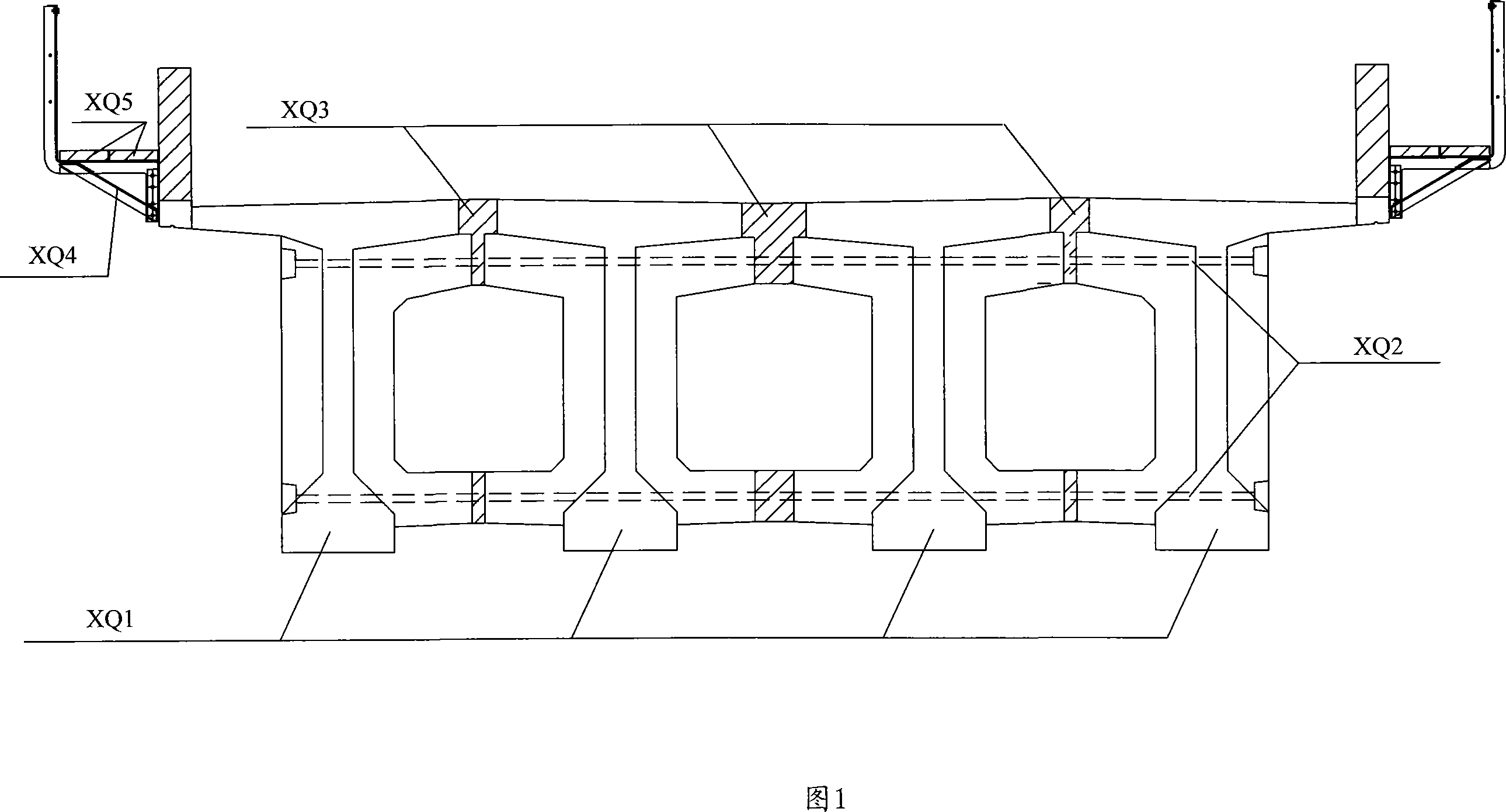

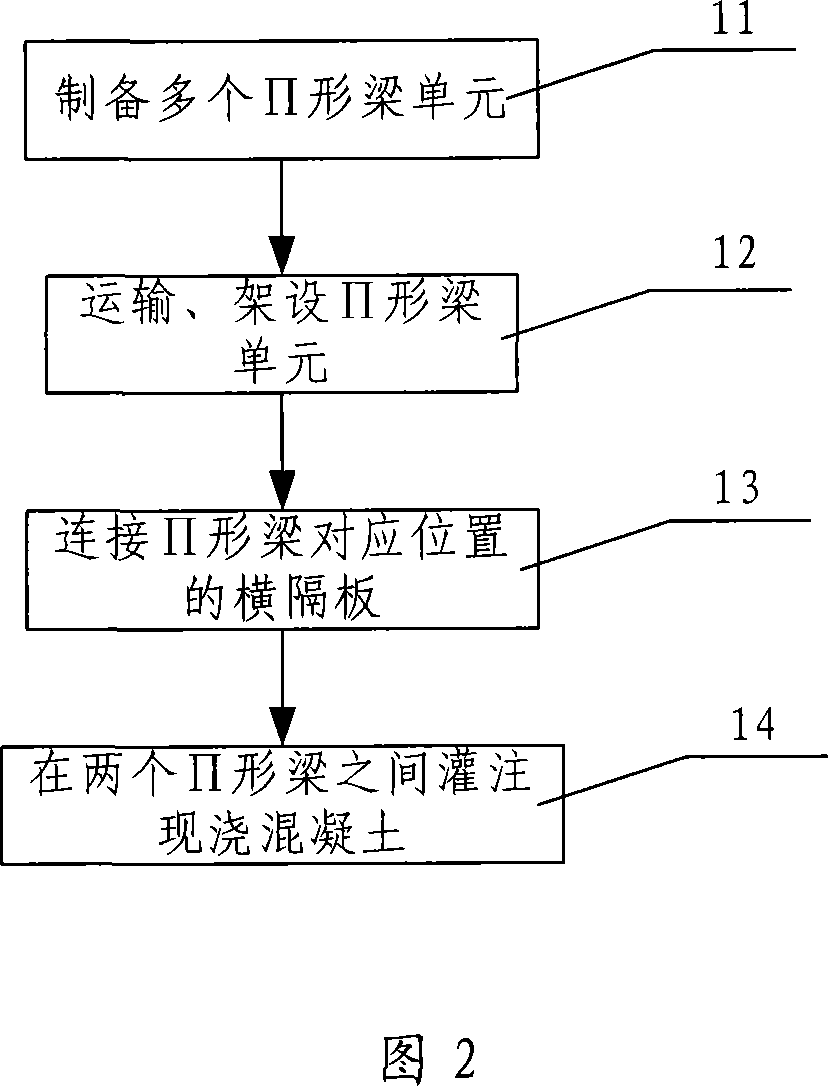

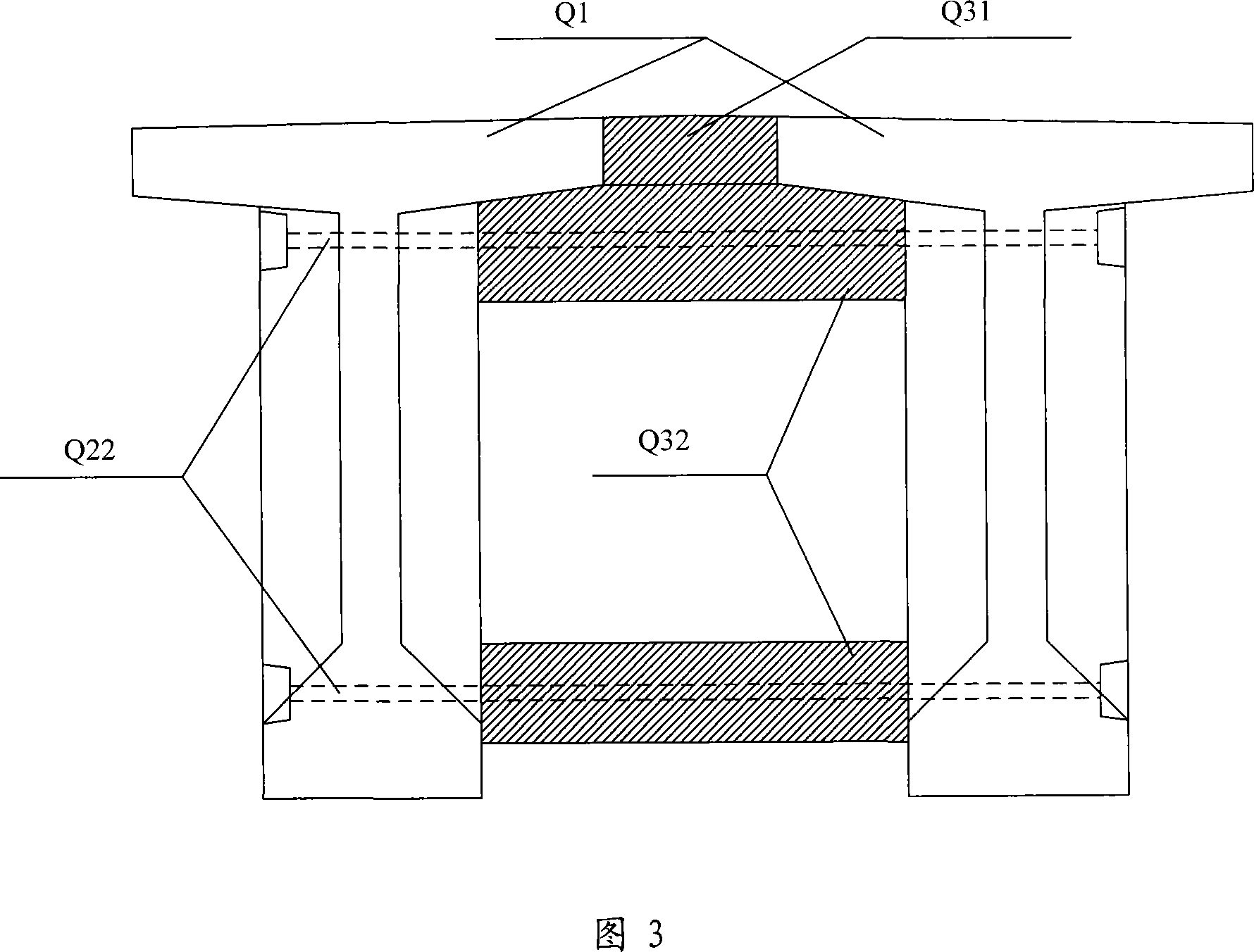

[0029] Fig. 2 is the flow chart of the embodiment of the method for erecting simply supported T-beam bridge of the present invention, and present embodiment is used for erecting double-track railway bridge, specifically comprises the following steps:

[0030] Step 11, preparing multiple ∏-shaped beam units. Assuming that the double-track railway bridge is a bridge with 10-hole beams, 20 ∏-shaped beam units need to be prepared. Firstly, connect two simply-supported T-beam decks and diaphragms horizontally under the bridge, and stretch the prestressed tendons of the diaphragms to form a ∏-shaped beam unit; the specific steps are as follows:

[0031] Under the bridge, place the two simply supported T-beams in accurate alignment according to the size set at the relative position during erection;

[0032] Bind the connecting steel bars of the diaphragm at the corresponding positions of the two simply supported T-beams and the connecting steel bars of the bridge deck, and connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com