Wall liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

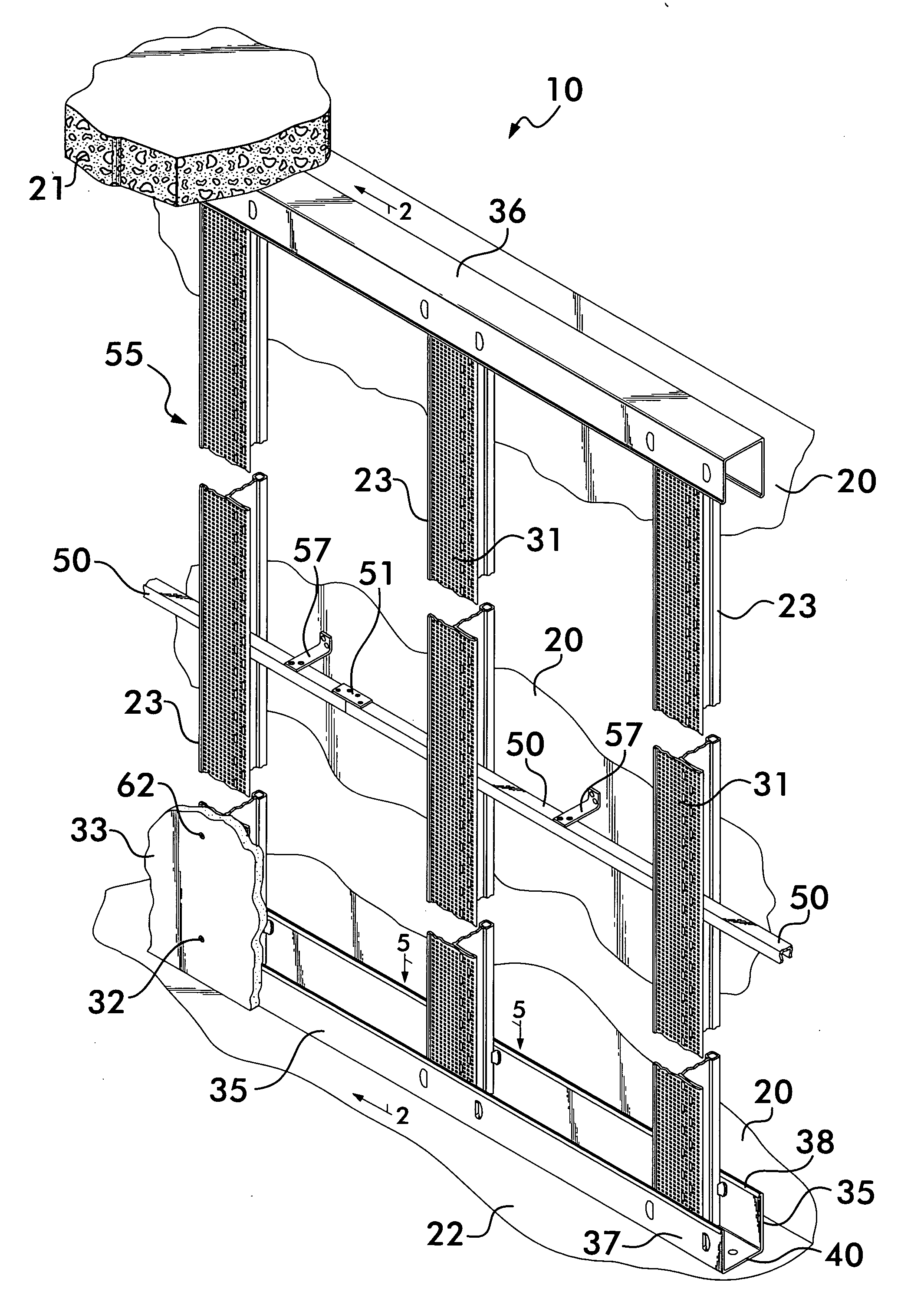

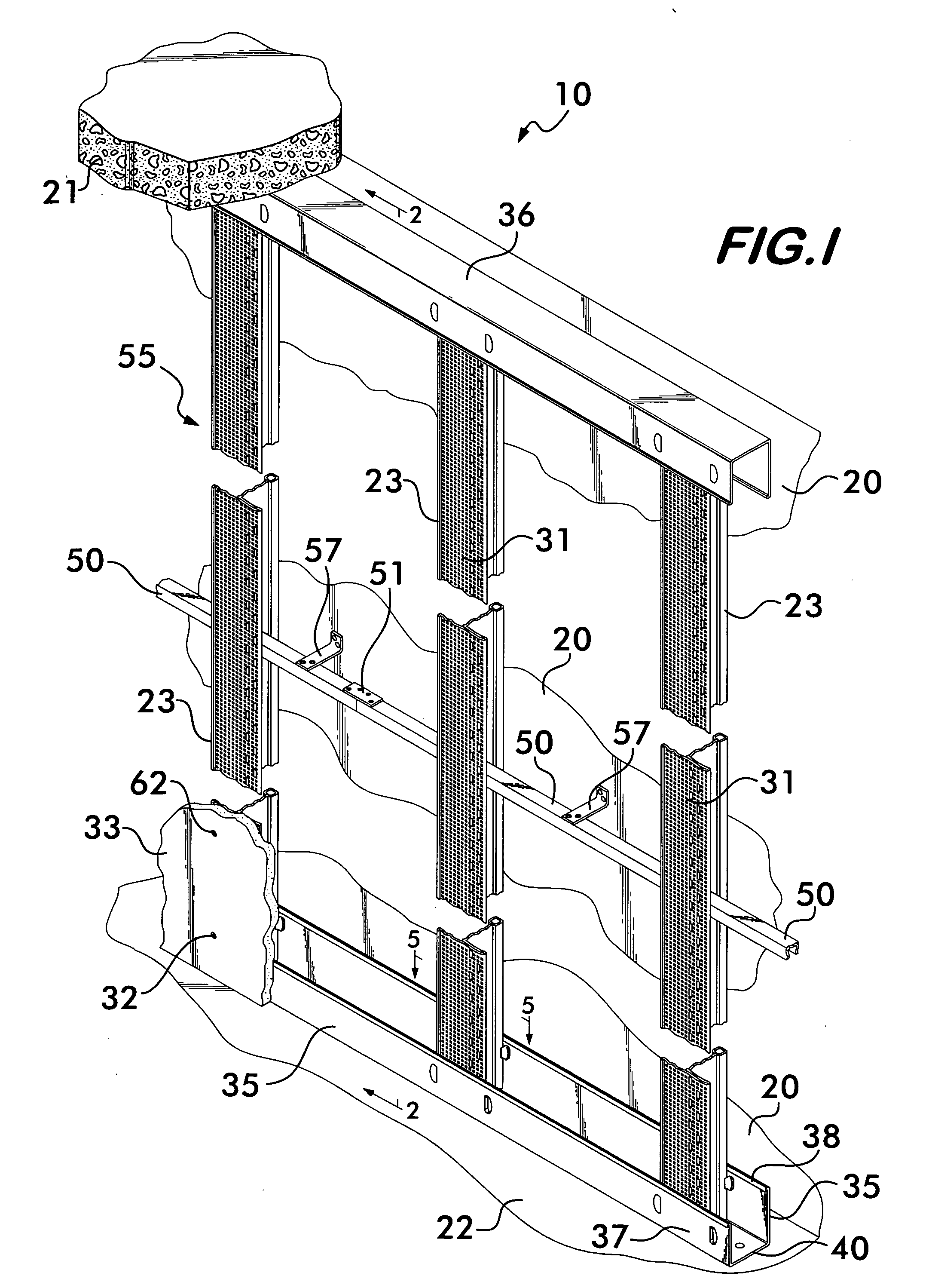

[0050]In the invention disclosed herein, the T-beam vertical stiffeners 23 have openings 42 spaced vertically in the webs26. The openings 42 have a larger upper portion 45, which is roughly rectangular, and a smaller bottom portion 46, which is U-shaped.

[0051]A strut 50 having a U-shaped cross section corresponding to the shape of the lower portion 46 of opening 42, that has been maneuvered through the larger opening 45, engages the bottom portion 46 in a force fit, as shown particularly in FIGS. 2, 7 and 7A. The struts 50 may be spliced together longitudinally with a splice plate 51, using pre-tapped holes in the strut 50 and plate 51.

[0052]The strut 50, which in the embodiment shown, has a cross section of an inverted U, reinforces each of the T-beam vertical stiffeners 23, from back wall 20.

[0053]Angle shaped brackets 57, spaced along strut 50, are anchored into back wall 20 with suitable fasteners, such as hardened nails 61, and are secured to strut 50 by screws 62. The brackets...

second embodiment

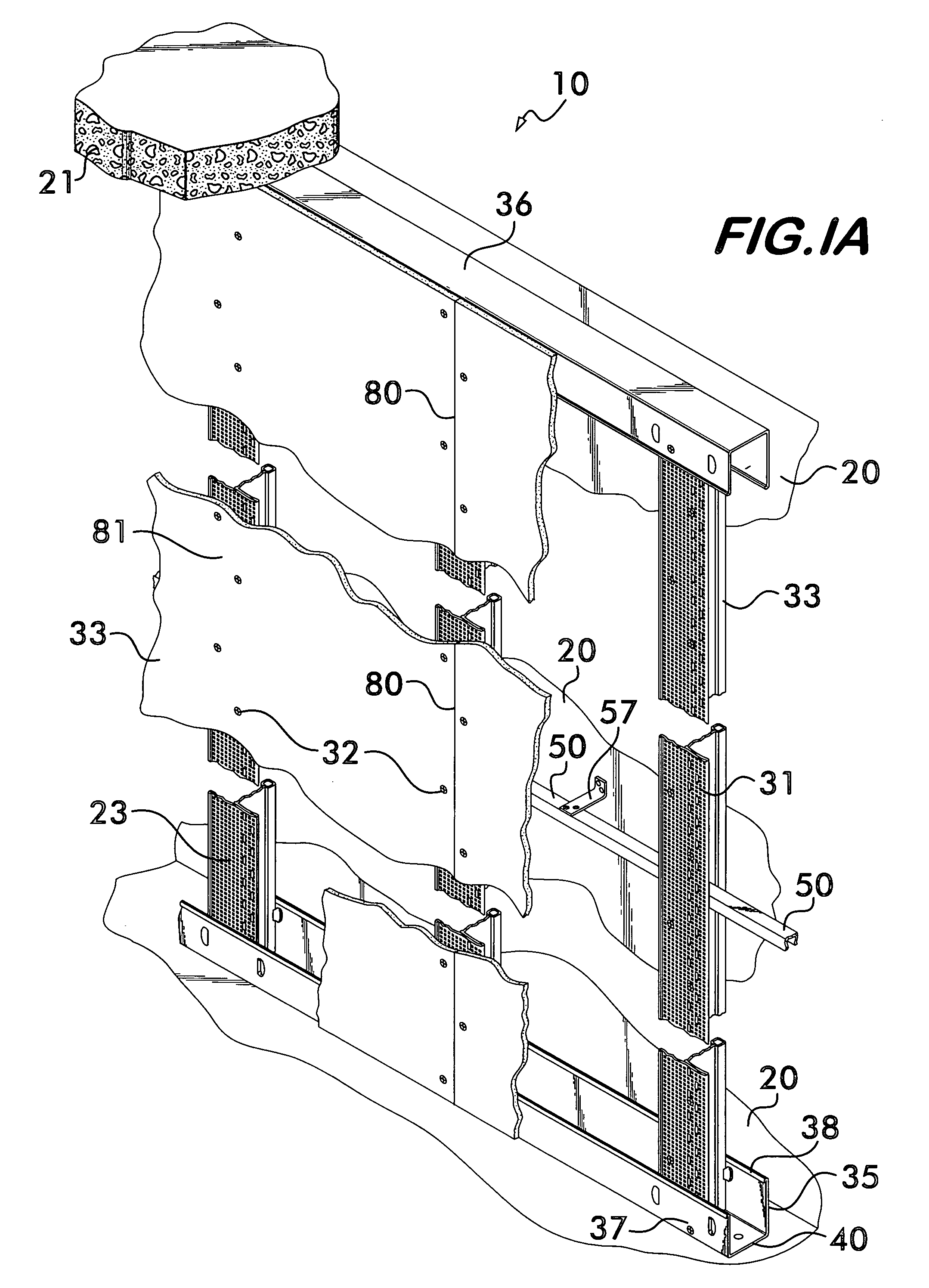

[0054]In the invention disclosed herein, struts 50 are not used, so that the T-beam vertical stiffeners 23 are not tied together, except at the top track 36 and bottom track 35, where they engage the tracks. Brackets 70 tie an individual T-beam vertical stiffener 23 to the structural wall 20 in back of the wall liner 10, at any desired vertical location on the T-beam vertical stiffener 23. The bracket 70 is L-shaped and has a first longer leg 71 and a second shorter leg 72.

[0055]An example of leg length may be 4% inches for the longer leg 71, and 1½ inches for the shorter leg 72. The legs 71 and 72 have holes 75 spaced in the legs at desired locations which provide for adjustability of the bracket 70. Where a structural back wall 20 varies in contour, a bracket 70 is adjusted to provide a solid connection between the structural back wall 20, and the T-beam vertical stiffener 23.

[0056]Examples of such adjustability are shown in FIG. 8, where in views (a) and (b), the shorter leg 72 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com