Assembly-type steel-wood combined beam column joint structure and construction method thereof

A technology of steel-wood combination and node structure, which is applied in the direction of building structure and construction, can solve the corresponding problems that have not been raised, and achieve the effects of improving construction efficiency, reducing the weight of the structure, and being easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

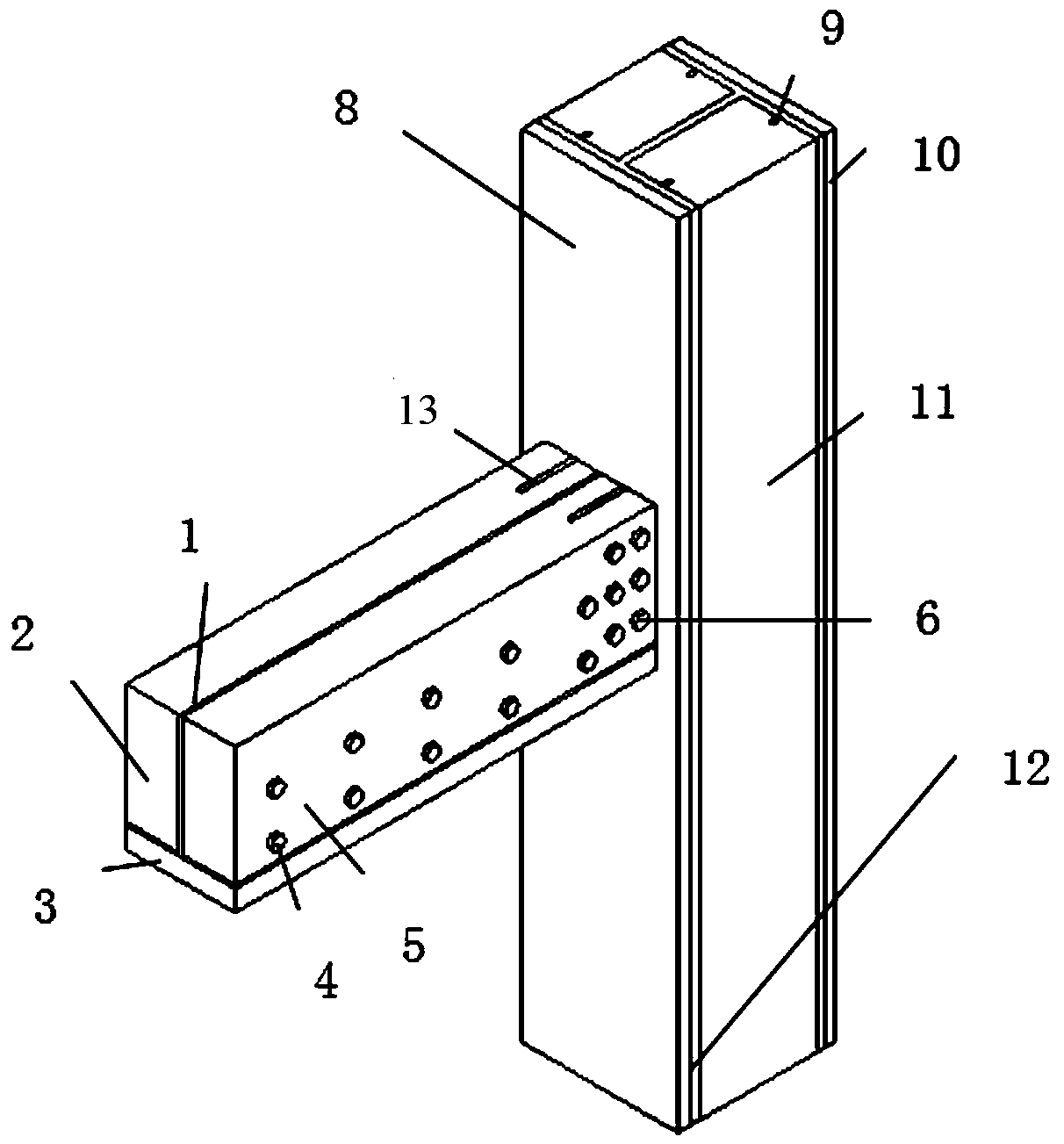

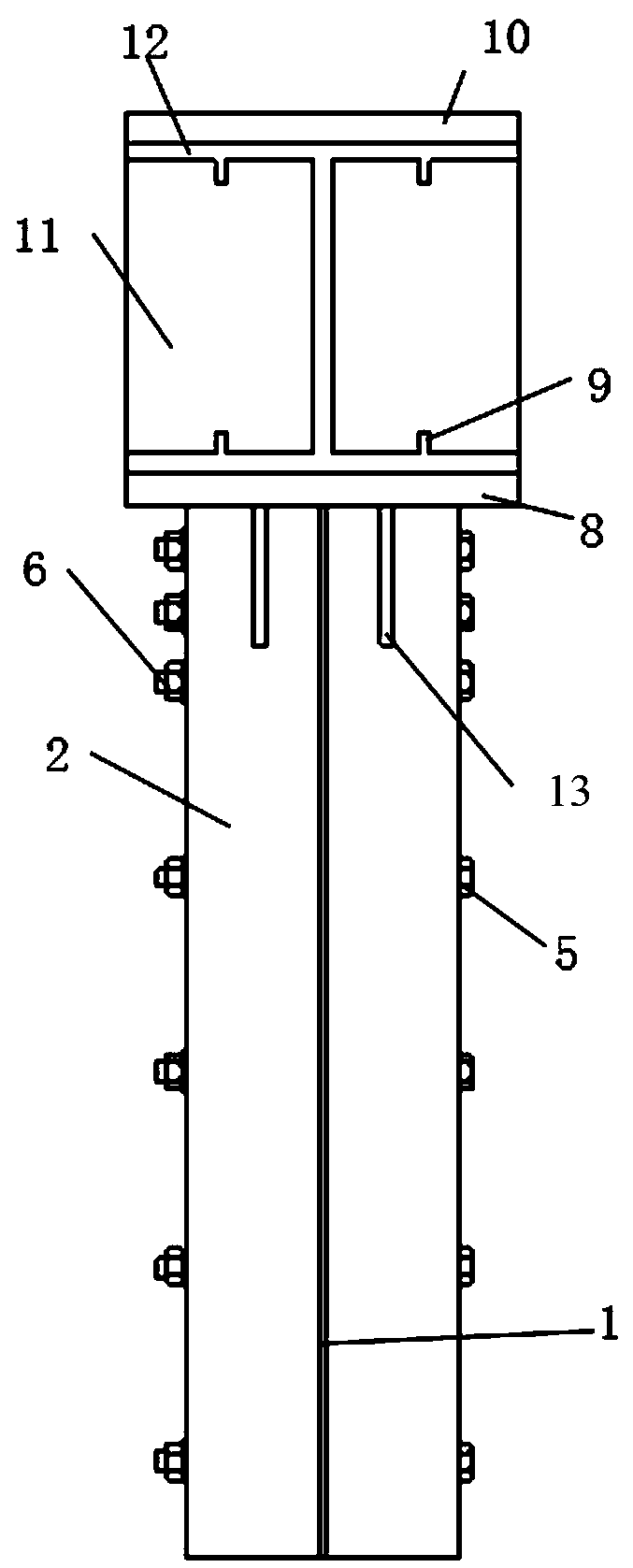

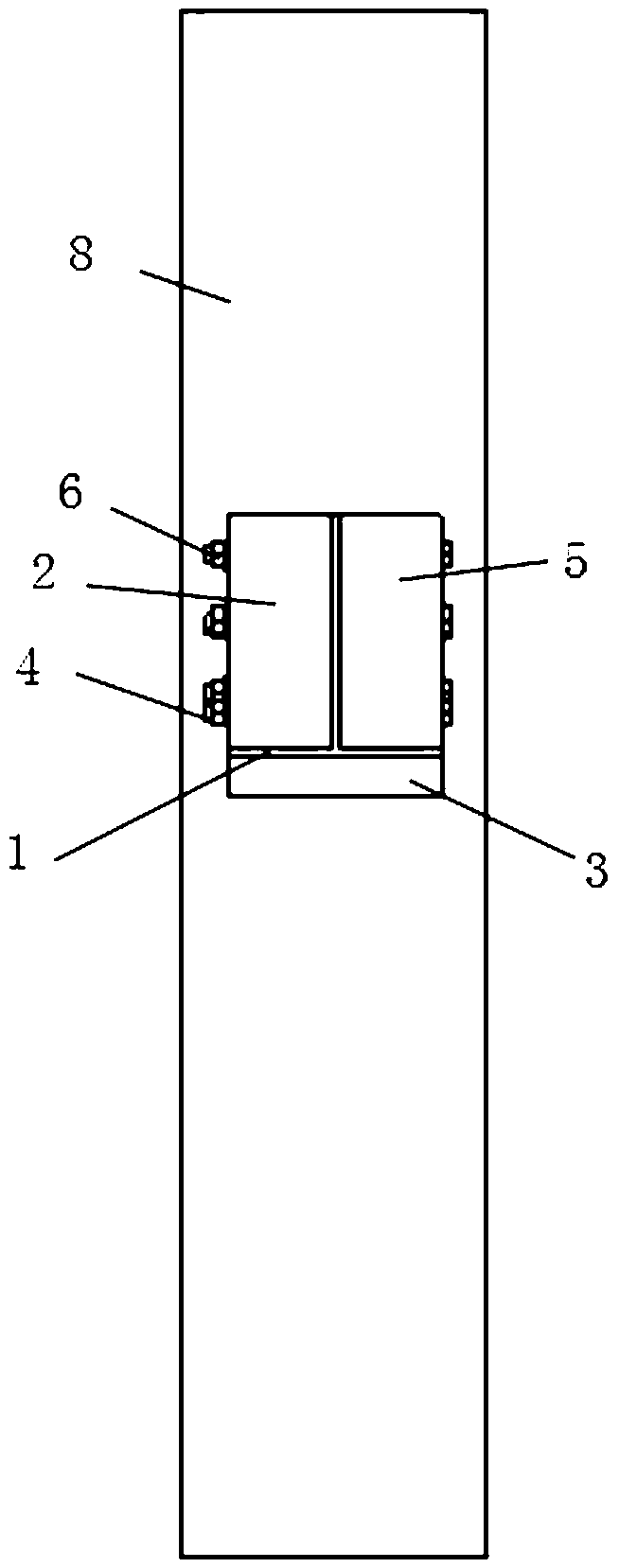

[0029] Such as Figure 1 to Figure 4 As shown, an assembled steel-wood composite beam-column node structure includes steel-wood composite beams and steel-wood composite columns perpendicular to each other, and the ends of the steel-wood composite beams are connected to the steel-wood composite columns through connectors; the steel-wood composite beams The composite beam comprises an inverted T-beam 1, a left plank 2 and a right plank 5 connected to both sides of the web of the inverted T-beam 1, and a lower plank 3 connected to the bottom surface of the flange of the inverted T-beam 1; the steel-wood composite column It includes an I-shaped column 12, an abdominal board 11 connected between the two flanges of the I-shaped column 12, and a front flange wooden board 8 and a rear flange wooden board 10 connected outside the two flanges of the I-shaped column 12. The connecting part includes a base plate 7 and two parallel boards 13 connected to the front of the base plate 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com