Pre-tensioning prestressed concrete short rib T-beam bridge and construction method thereof

A concrete and prestressed technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of disease, difficult construction quality and durability control of post-tensioning method, and height of prefabricated T-beam bridges, so as to achieve construction quality assurance , The effect of convenient factory prefabrication and saving arable land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

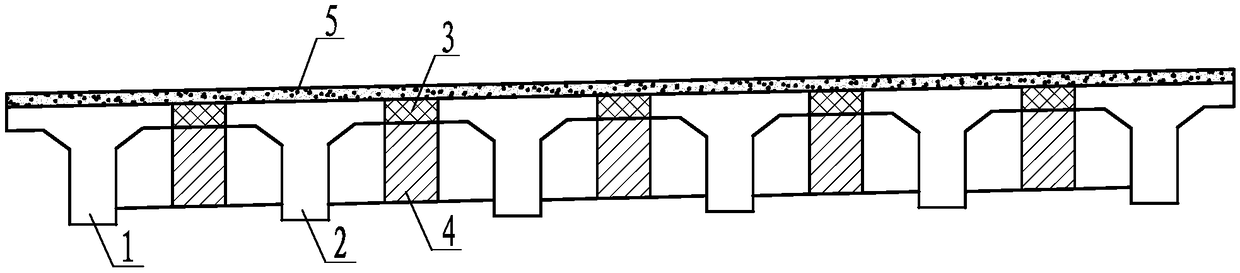

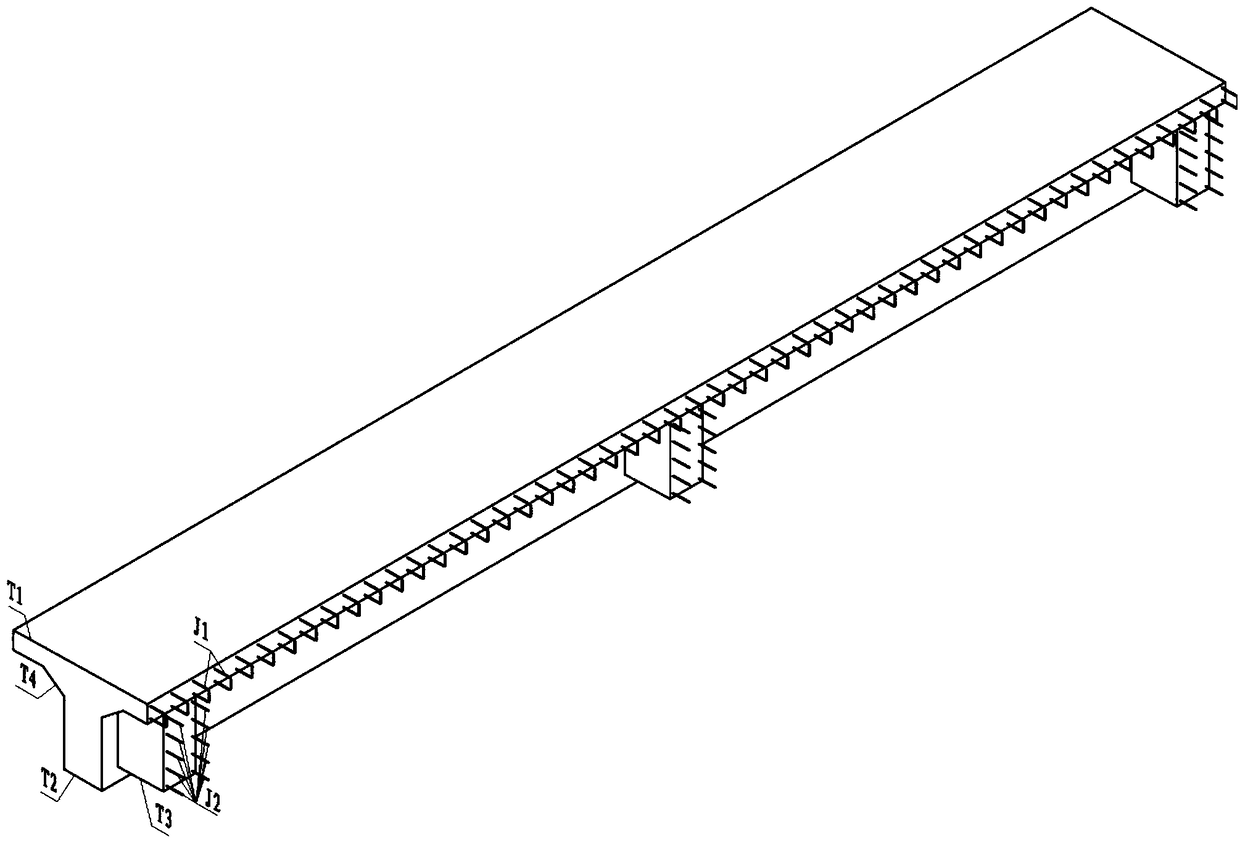

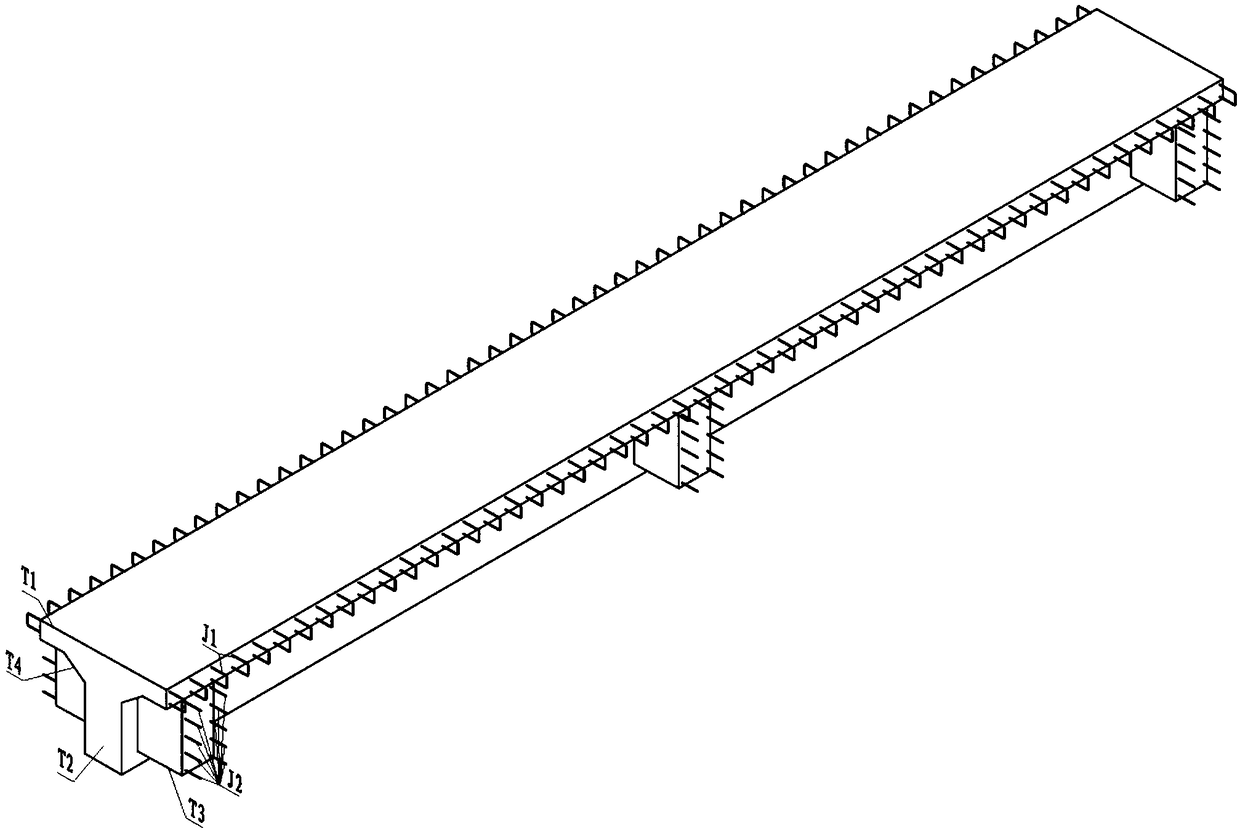

[0046] Such as figure 1 As shown, the pretensioned prestressed concrete low-rib T-beam bridge of the present invention includes several pieces of low-rib T-beams, the two pieces of low-rib T-beams on the outside are side beams 1, and the low-rib T-beams between the two side beams 1 are middle beams 2. The flange slab concrete cast-in-place joints 3 and diaphragm concrete cast-in-place joints 4 are set between each low-rib T-beam; the reinforced concrete bridge deck cast-in-place layer 5 is set on the top of each low-rib T-beam; The ribbed T-beams are horizontally connected as a whole through the concrete cast-in-place joints 3 of the flange slab, the concrete cast-in-place joints 4 of the transverse diaphragm, and the cast-in-place layer of the bridge dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com