Subgrade treatment structure of soft soil areas and construction technology thereof

A construction technology and subgrade technology, applied in roads, roads, buildings, etc., can solve problems such as the inability to meet the minimum thickness requirements of the lime soil adjustment layer, and achieve the effects of good overall stability, shortened construction period, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

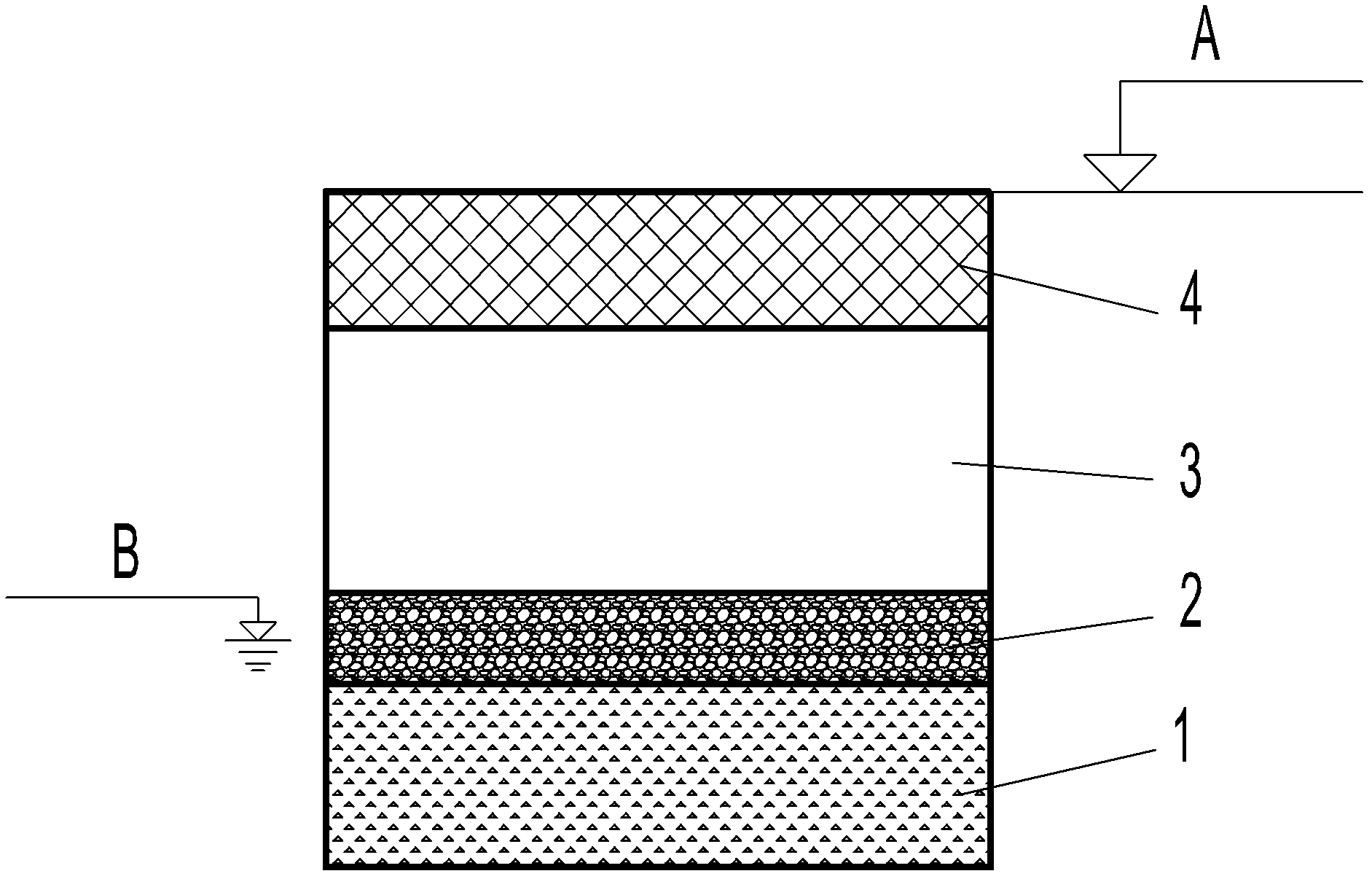

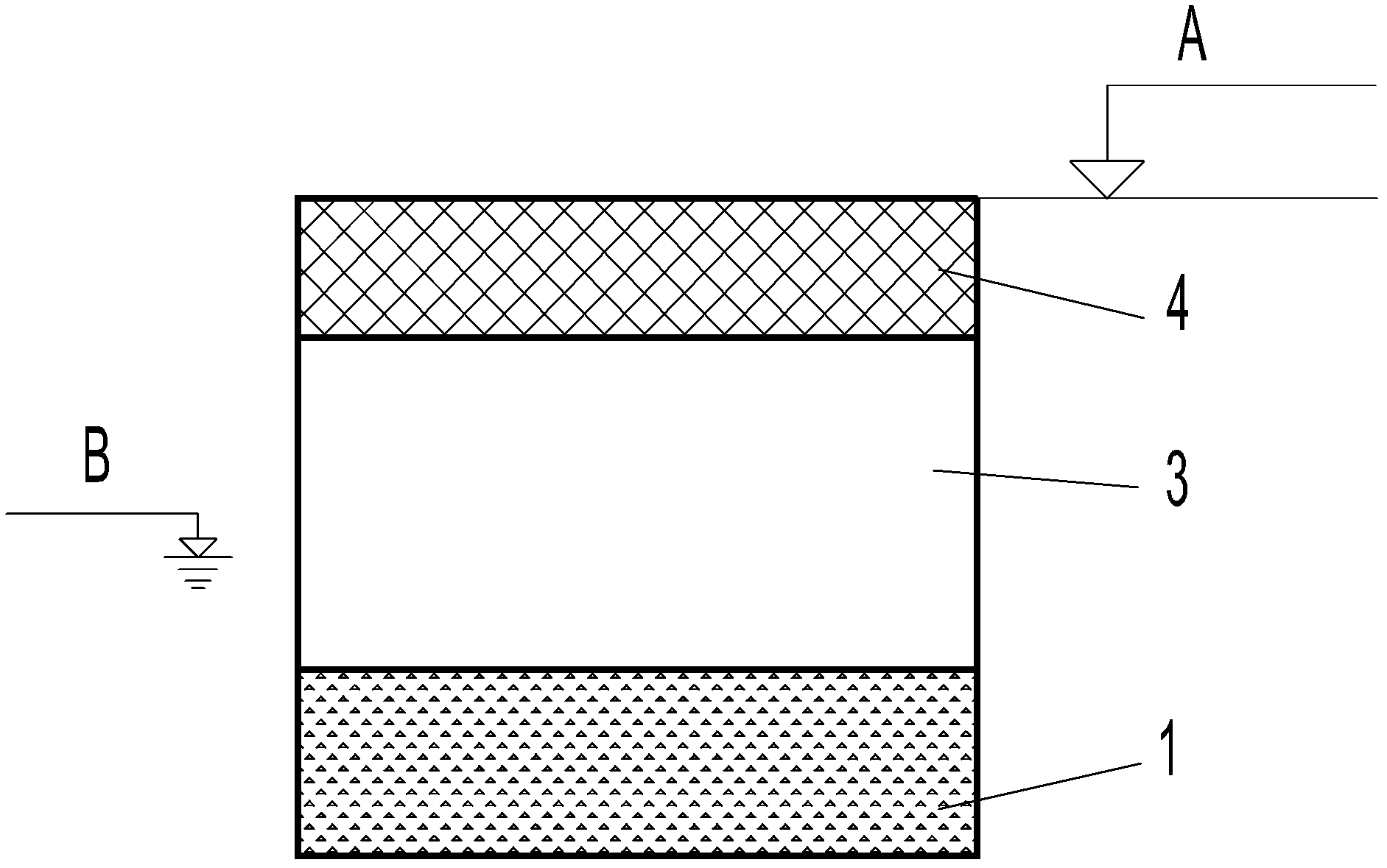

[0027] Such as figure 2 As shown, a specific embodiment of the subgrade treatment structure in the soft soil area of the present invention is arranged on the soil foundation, and a 60 cm to 80 cm mountain soil supporting layer 1 and a lime soil adjustment layer 3 are arranged successively from bottom to top And pavement structure layer 4. Wherein, the ash content of the lime soil adjustment layer 3 is 8% to 10%.

[0028] In this embodiment, the design elevation A of the subgrade treatment structure is 3 meters (in other embodiments, according to the actual situation of the construction environment, the design elevation A can be adjusted, and may be 2.6 meters, 2.8 meters, 3.0 meters, 3.2 meters, 3.4 meters) Various possibilities such as meters), the groundwater level B is located in the lime soil adjustment layer 3.

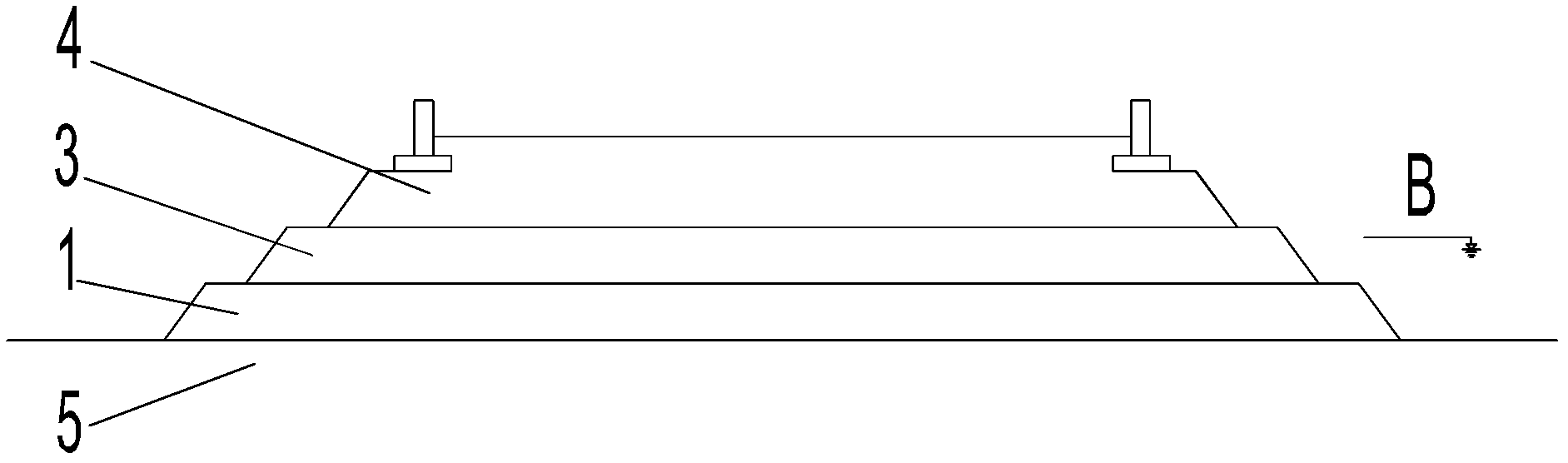

[0029] see Figure 4 As shown, the subgrade treatment structure also includes water seepage grooves 51 located on both sides of the soil foundation 5 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com