Prefabricated T beam transferring trolley

A trolley and beam-moving technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large area of walkway, long processing cycle, T-beam overturning, etc., and achieves strong adaptability to site conditions, The foundation and foundation requirements are low, and the effect of avoiding tilting or overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

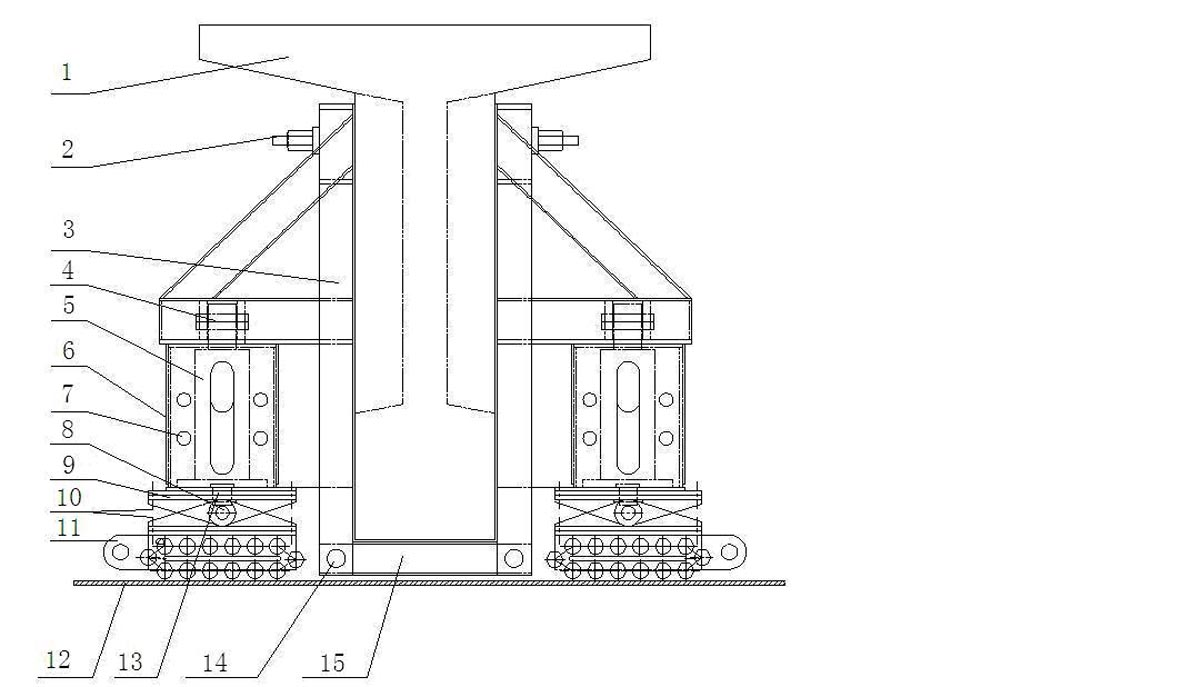

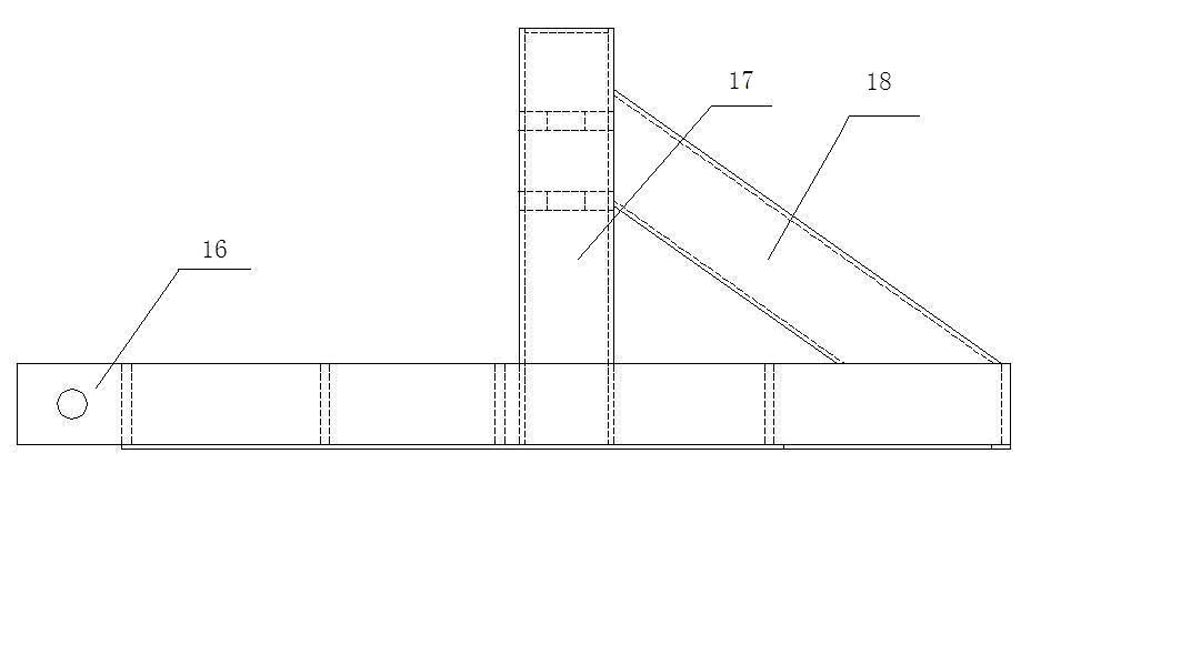

[0030] attached figure 1 Shown is a front view of a prefabricated T-beam beam-moving trolley of the present invention. It can be seen from the figure that in this embodiment, the functional structure of the beam-moving trolley is mainly divided into the traveling mechanism, the jacking mechanism installed on the traveling mechanism, and the T beam connected to the jacking mechanism for clamping the prefabricated T beam Clamping device: including joist bottom plate, heavy object transfer device, pendulum shaft, hydraulic cylinder and casing, trolley bracket pull bolts and other components.

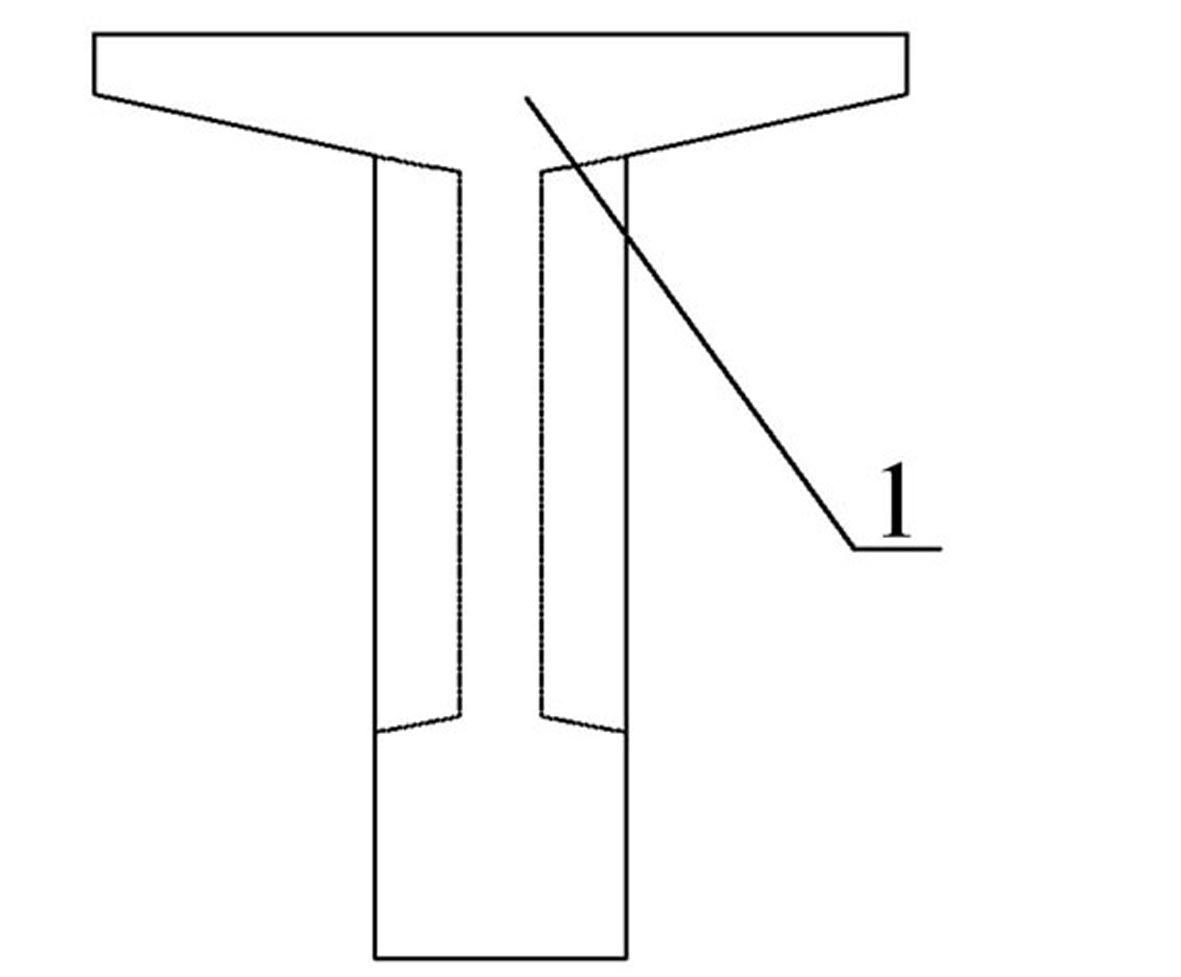

[0031] Depend on figure 1 It can be seen that the cross-section of the T-beam clamping device composed of two trolley brackets 3 and the jois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com