Prestress-steel-wire-rope-bending-shearing-reinforced concrete T beam and reinforcing method thereof

A concrete and steel wire rope technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of increasing the self-weight of original components, peeling damage of anchorage ends, and insufficient shear resistance, so as to improve the overall bearing capacity and reduce the influence of structural self-weight , to avoid the effect of stress hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

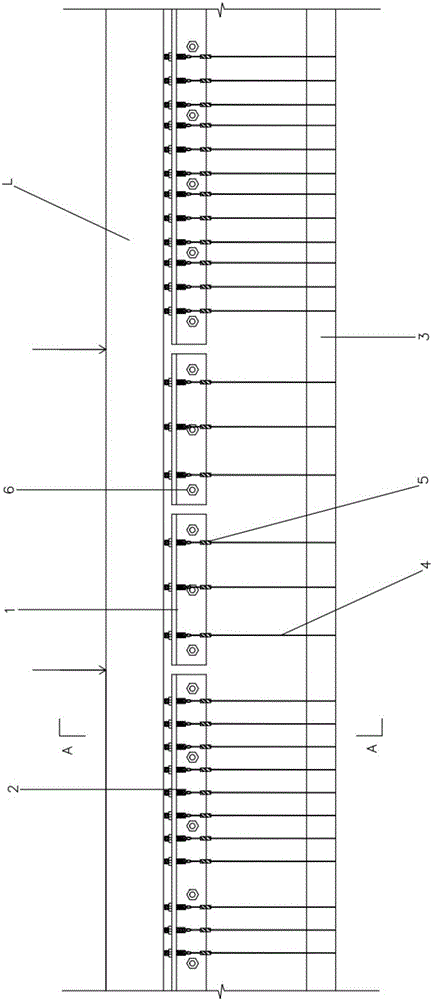

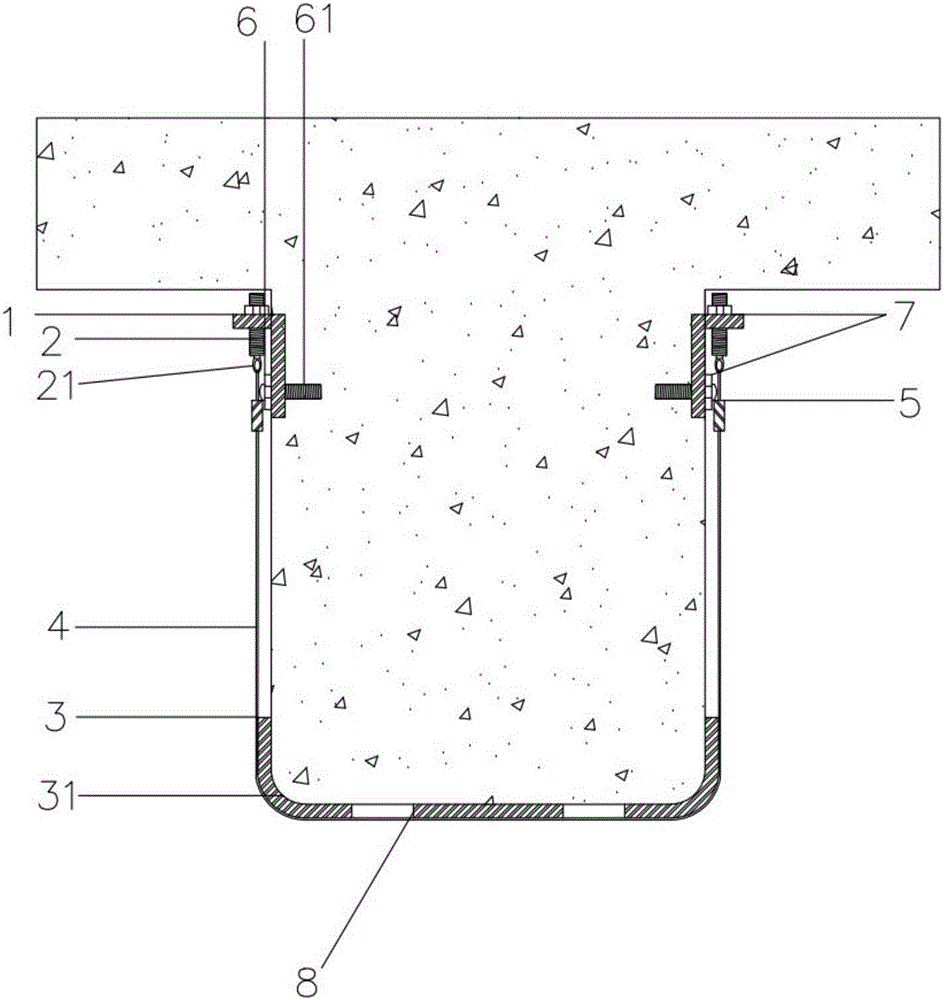

[0036] Such as figure 1 , figure 2 A prestressed steel wire rope bending-shear reinforced concrete T-beam shown includes a reinforcement system arranged on the concrete T-beam. The reinforcement system includes a steel wire rope 4, a plurality of bending-resistant steel plates 8 installed at the bottom of the concrete T-beam L and horizontally fixed A plurality of angle steels 1 on both sides of the web plate of the concrete T-beam L has a plurality of bolt holes along its length direction on the other side of each angle steel 1, and an adjustable bolt 2 is arranged in each bolt hole, and one end of the adjustable bolt 2 is arranged After the ring 21 and the steel wire rope 4 go around the bottom of the beam, the two ends respectively pass through the corresponding ring 21 and are tensioned. A protection system is also provided outside the reinforcement system. A ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com