Prefabricated steel-concrete combination T beam with corrugated steel web and construction method

A technology of corrugated steel webs and construction methods, which is applied to bridges, bridge parts, bridge construction, etc., can solve problems such as stability problems in the erection process, impact on ground traffic and surrounding environment, and large residual stress of flat steel plate welding. Achieve the effects of avoiding construction and transportation problems, less on-site construction workload, and less on-site welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

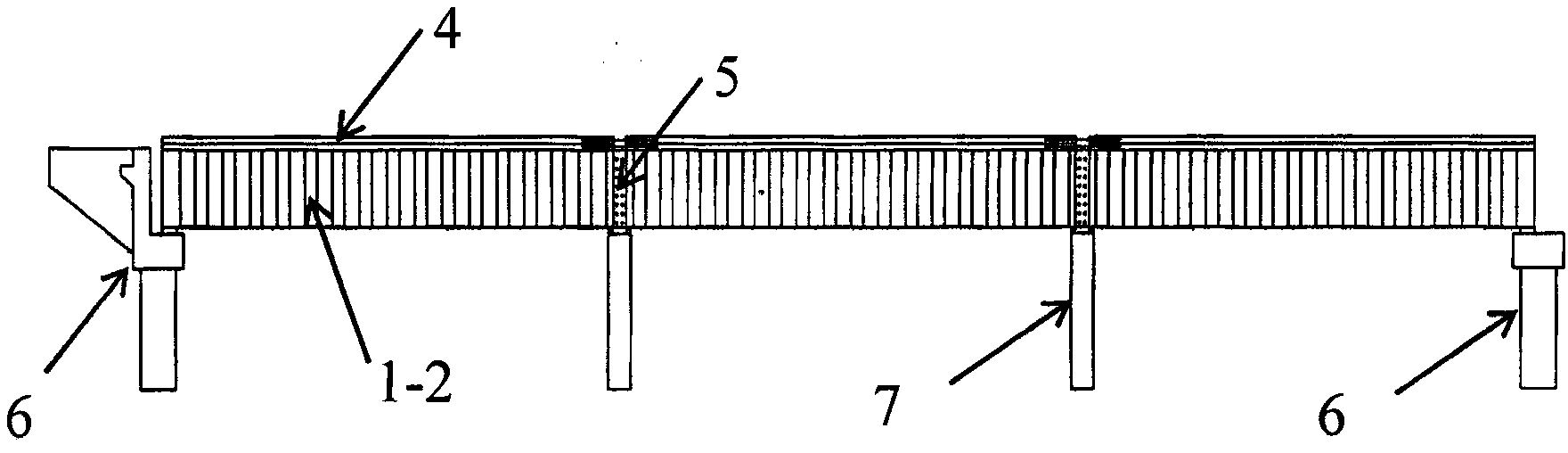

[0027] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments, and the present invention can also be used in the construction of multi-span continuous beams.

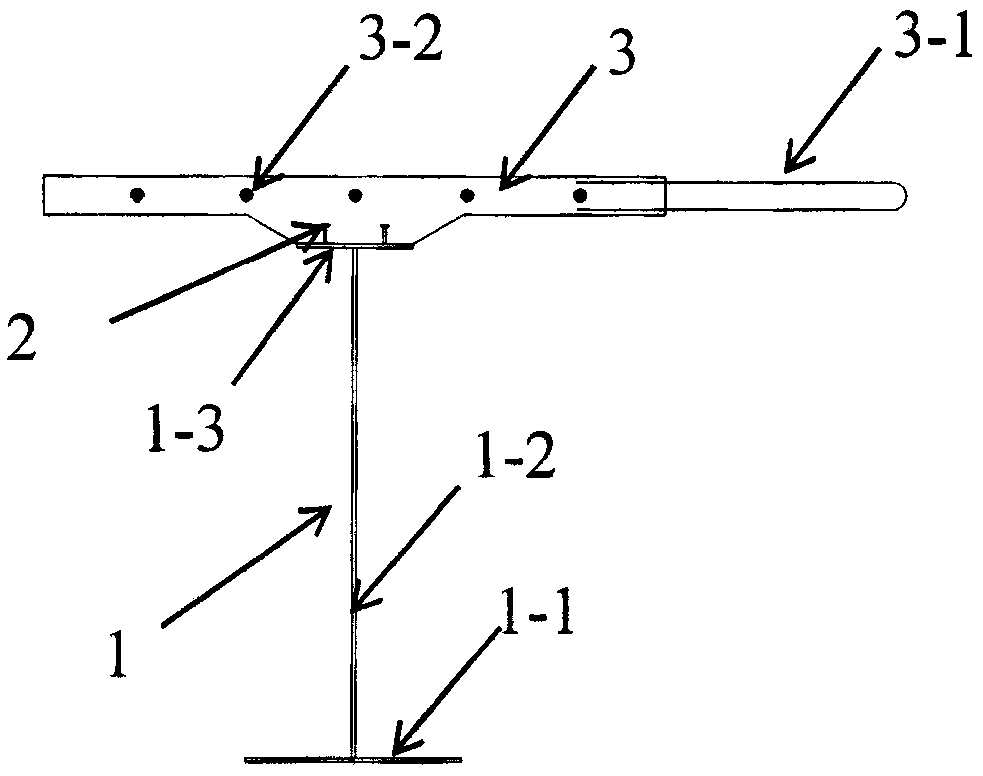

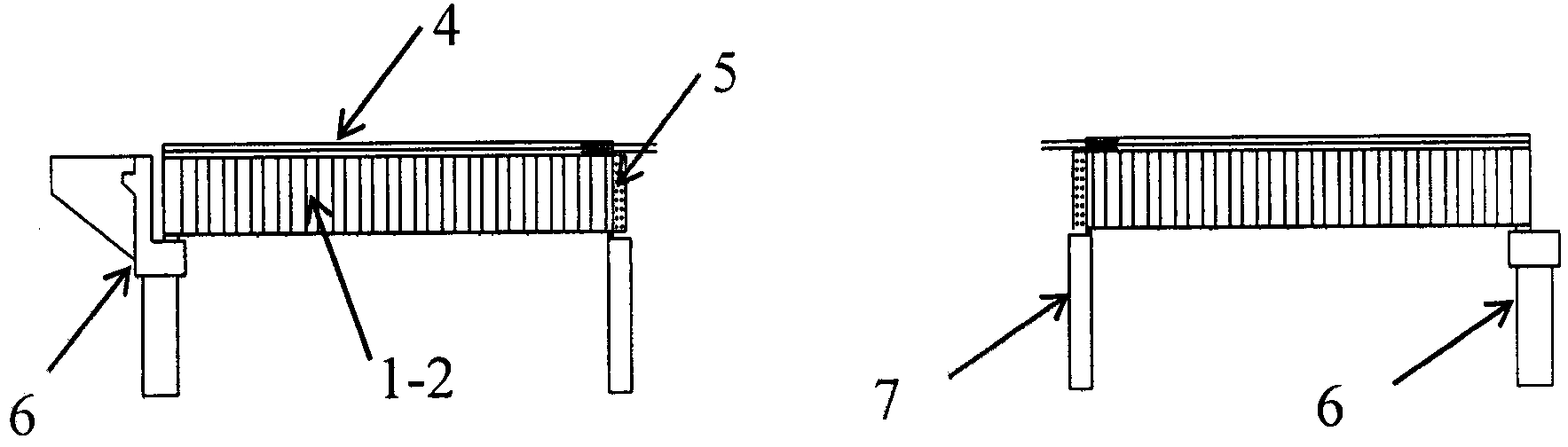

[0028] like Figure 1-9 As shown: the prefabricated steel-concrete composite T-beam using corrugated steel web described in this embodiment includes a plurality of prefabricated steel- Concrete composite T-beam beam unit 4, adjacent steel-concrete composite T-beam beam unit 4 passes through the vertical connection section 5 between the I-shaped corrugated steel web steel beams and the wet joint beam 11 at the beam end of the poured prefabricated composite beam unit To form a whole, the composite beam segment unit 4 is reserved with connecting reinforcement bars 3-1 in the transverse direction and connecting reinforcement bars 3-2 in the longitudinal direction. The I-shaped corrugated steel web ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com