Construction technology for simply supported and continuously supported external prestressed continuous beam bridge T-shaped section

A technology of external prestressing and construction technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of insufficient bridge bearing capacity, unguaranteed grouting quality, affecting structural durability, etc., and achieves reduction of prestressed friction loss, Easy to maintain and replace, easy to transport and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

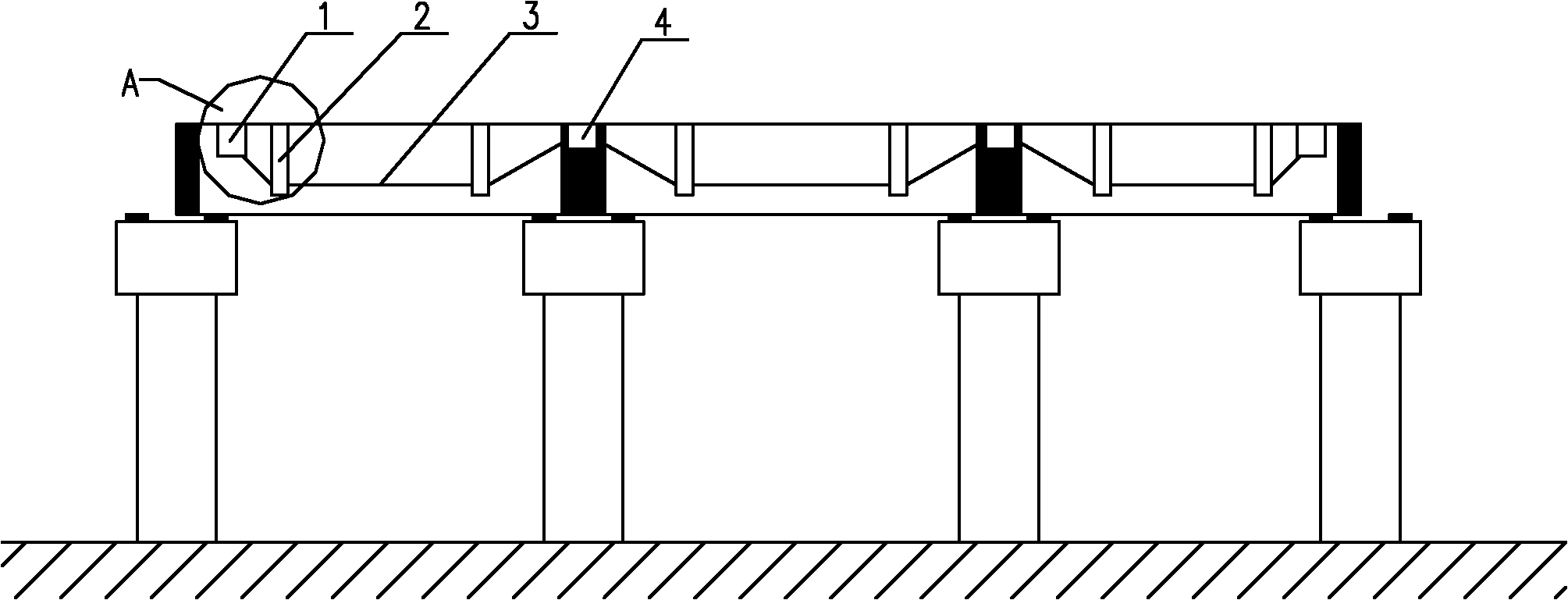

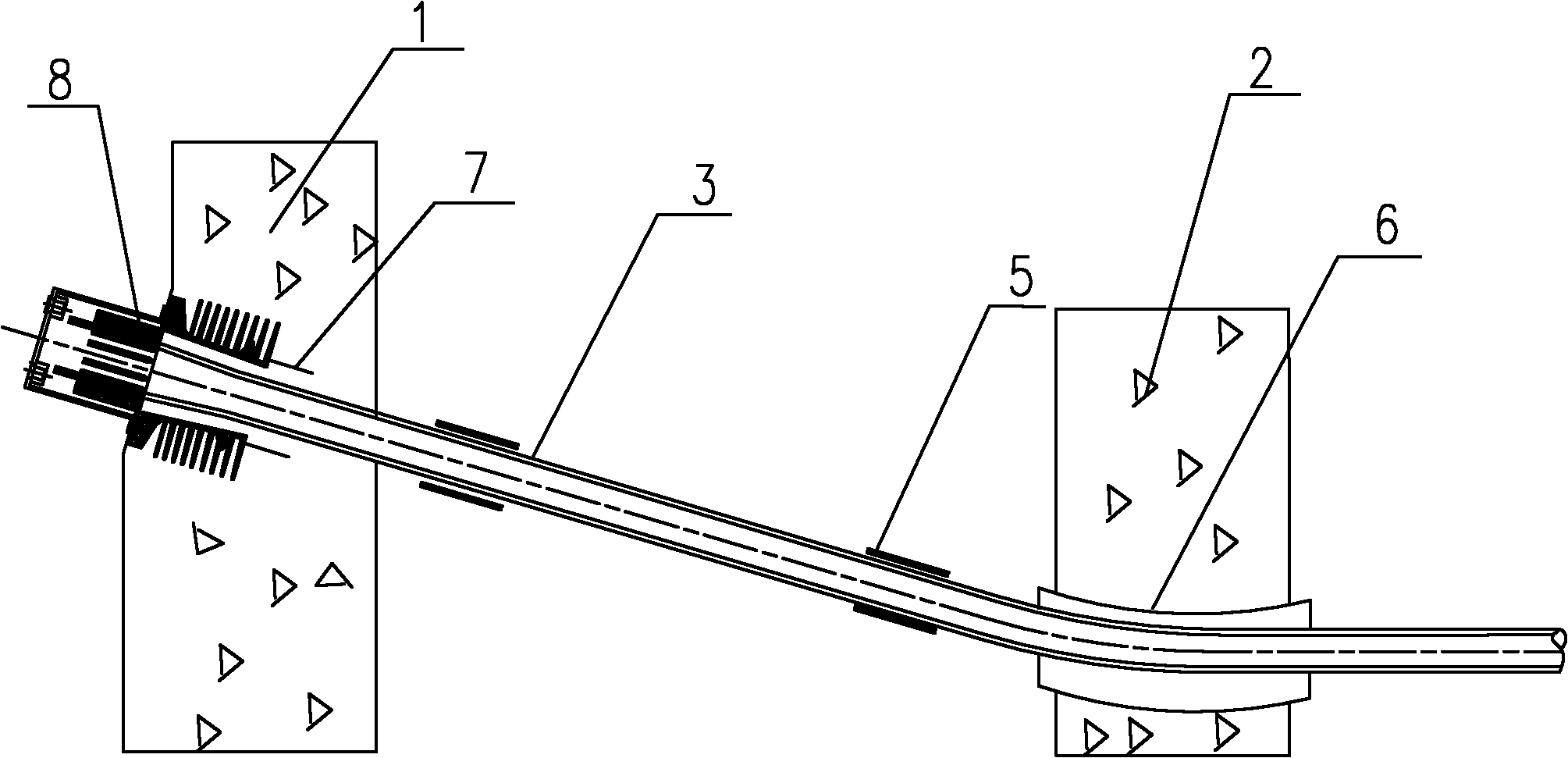

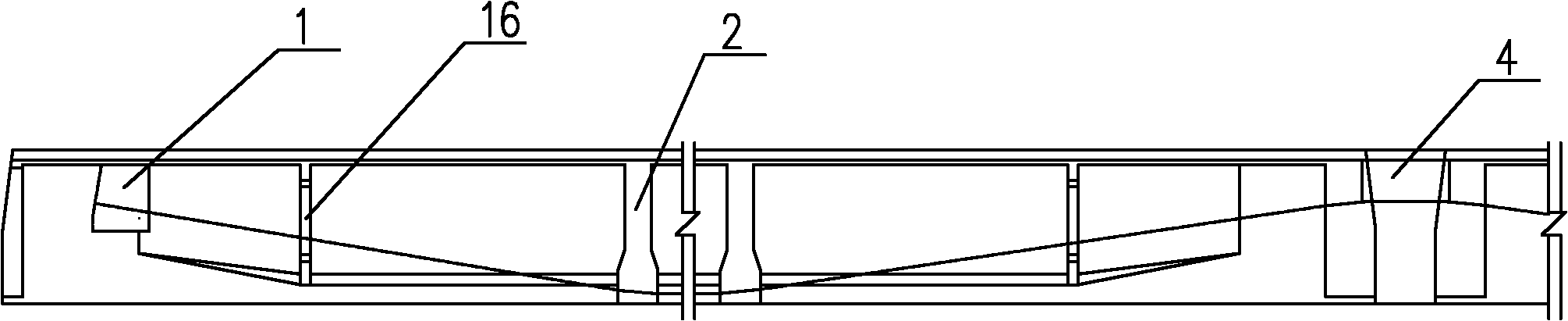

[0029] Example: such as figure 1 As shown, it is a three-span concrete T-beam bridge, which adopts an externally prestressed continuous T-beam bridge that is simply supported and prefabricated first, and then the structure is continuous. ) girder bridge, the load class is automobile-super class 20, trailer-120, and the concrete T-beam is made of C50 concrete. Such as Figure 5 As shown, in order to maintain coordination with the height of the front and rear joint beams and reduce the type of beam height, the beam height of the concrete T beam is 2.3 m, and the concrete T beam adopts a T-shaped section. The concrete T beam includes a wing plate 15, a web 17, a horseshoe 14, Diaphragm 16 and the external prestressing beam 3 arranged outside the web 17, the steering device 6 and the anchoring system, the external prestressing beam 3 is arranged outside the web 17, so that the beam rib width near the mid-span is changed from the original 22cm is reduced to 18cm, and the width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com