Construction method of longitudinal wet joint formwork of prefabricated T beam or box beam

A construction method and wet joint technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large demand for steel pipes and section steel, poor safety, stability, waste of engineering time, etc., to save steel, The effect of convenient installation and dismantling, reducing engineering cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

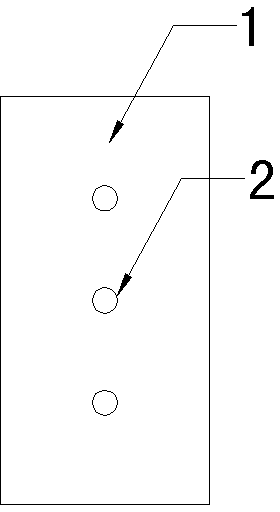

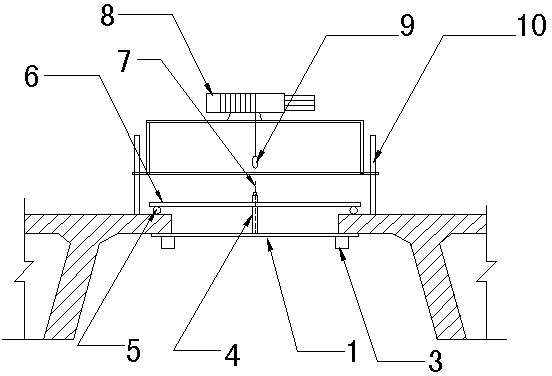

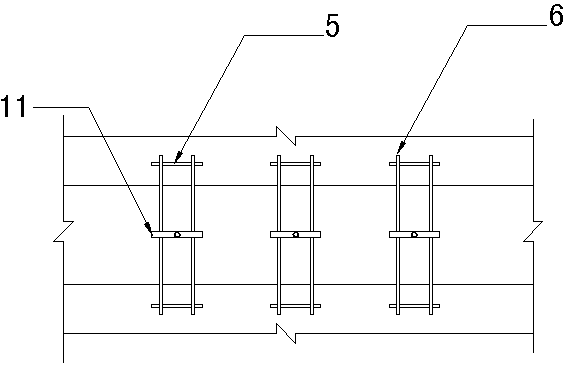

[0011] From figure 1 , figure 2 , image 3 It can be seen that the construction tools and materials of the present invention include: trolley frame, wheel, axle, small electric hoist, steel wire rope, suspension ring, wet joint bottom mold, pull rod, bridge steel bar, support pad steel bar, card Buckle, nut, PVC pipe, adjustable wrench.

[0012] The bottom mold is made of bamboo plywood 1 (thickness ≥ 1.5cm); a row of tie rod holes 2 is drilled at the center line, the length and width are determined according to the wet joints, and a stiffening square wood 3 is arranged at the bottom of the bamboo plywood 1; a trolley is pushed The frame of 10 is welded with Φ28~32 threaded steel bars; the wheels and axles are pallet wheels and axles, and the load is about 300kg; the power of small electric hoist 8 is 3~6kw; the steel wire rope of the trolley is Φ6~14 lifting wire rope, Pull bar 7 adopts Φ12~16 threaded steel bar, and pull bar 7 overcoats has PVC pipe 4, and supporting pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com