Overall dismantling and longitudinal slipping construction method of T beam formwork

A construction method and beam formwork technology, applied in the directions of manufacturing tools, unloading devices, etc., can solve the problems of difficulty in controlling the shape and appearance quality of the beam body, high risk of high-risk source lifting and hoisting operations, and deviation of the size of the prefabricated beam body, etc. Achieve the effect of improving the appearance and appearance quality, shortening the construction period of the project, and ensuring the size of the beam body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

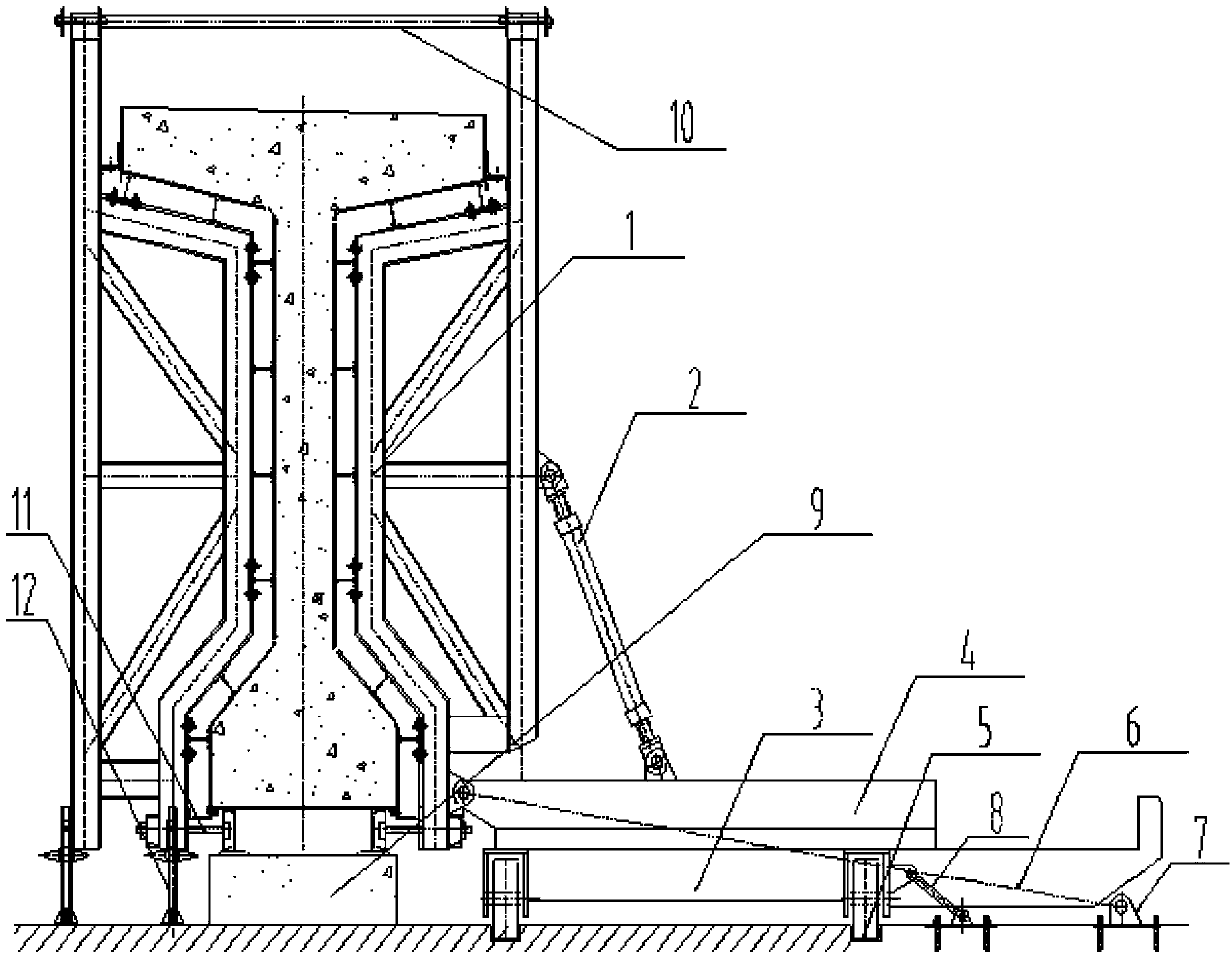

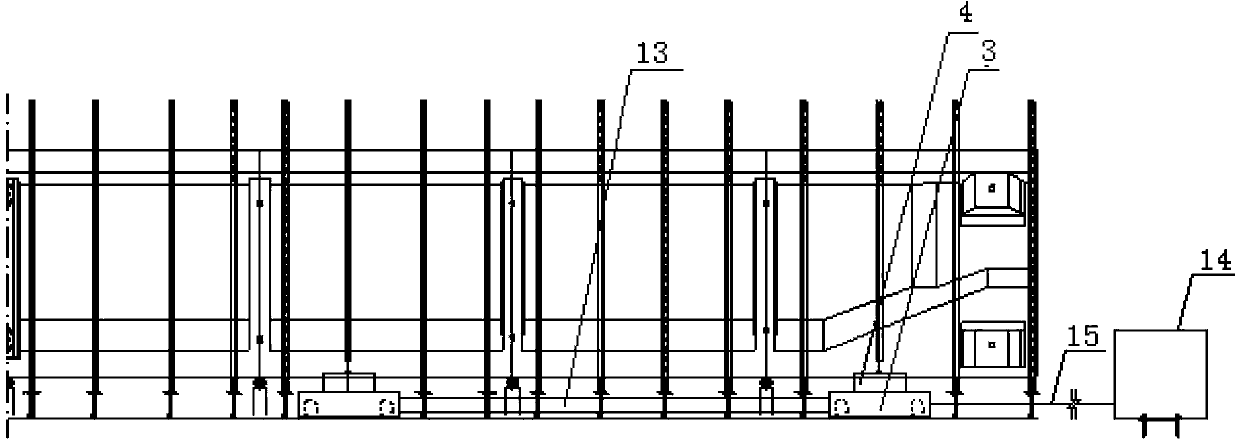

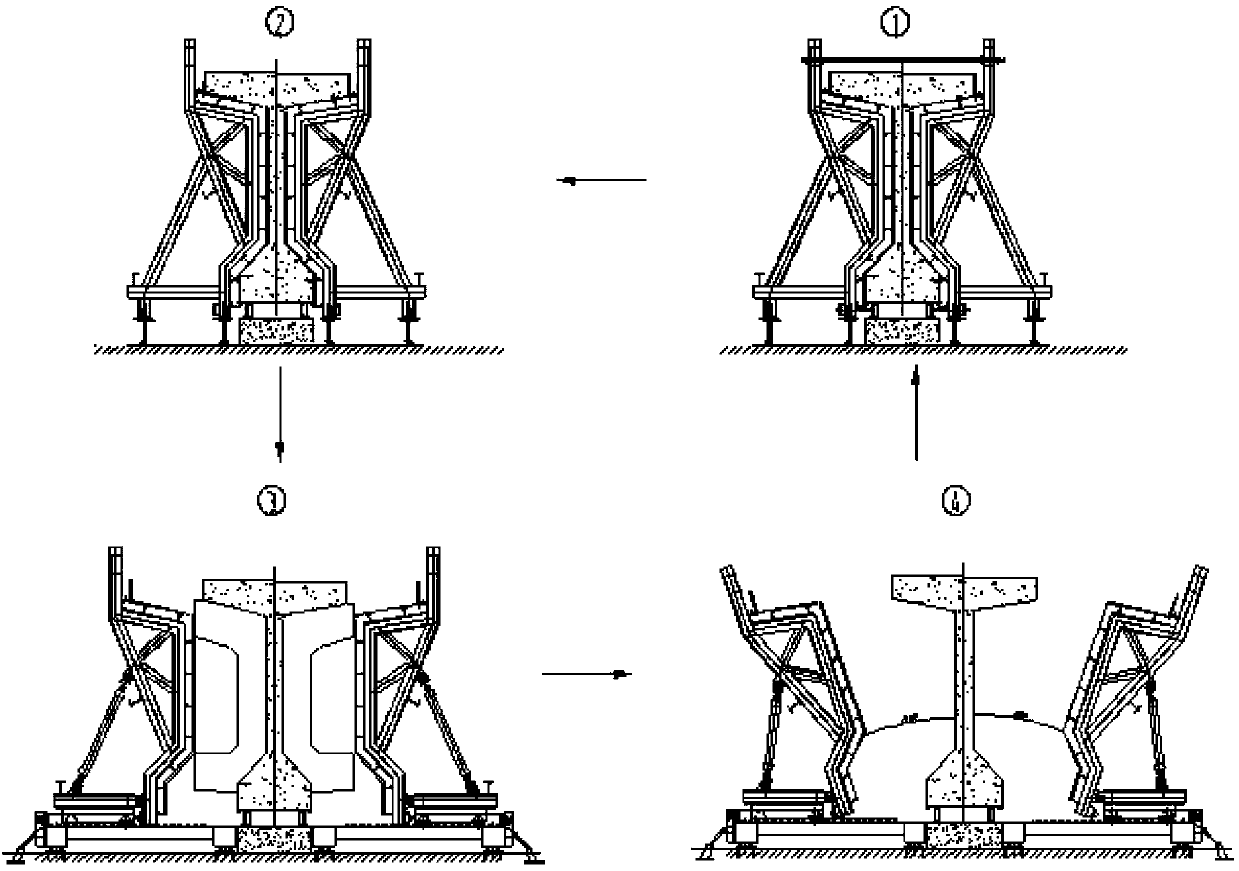

[0040] Referring to the accompanying drawings, the overall removal of the T-beam formwork and the construction method of longitudinal sliding include the following construction steps:

[0041] (1) During the horizontal movement and vertical movement of the formwork installation and removal, the unilateral formwork is kept as a whole. During the construction process, it is not necessary to disassemble the unilateral integral formwork into segmental formwork or assemble the unilateral formwork from segmental formwork. ;

[0042] (2) When traversing, the one-sided overall formwork is supported on the traversing trolley 4, and the thorn wheel anchored on the ground and connected to the formwork is rotated to expand and contract the thorn wheel screw, so that the formwork is approached on the traversing trolley 4 and away from the beam-making pedestal, that is, to realize the installation and removal of the formwork; when moving longitudinally, a winch anchored to the ground is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com