Loom beating-up force control system and method

A technology for machine beating-up force and control system, which is applied in the field of textile machine beating-up force control system and textile machine beating-up force control field, can solve problems such as driving marks and parking gears, and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

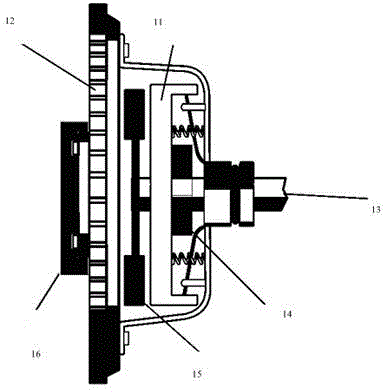

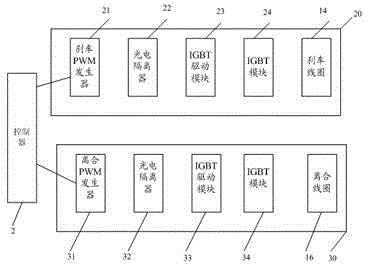

[0026] The reed of the loom is connected to the main shaft of the loom with a clutch brake system through a series of complex mechanical structures, thereby converting the rotational motion of the main shaft into the reciprocating motion of the reed. This is a common mechanism on existing looms, so it will not be described in detail. The weft yarn enters the weaving mouth through the opening of the heald frame, and then the reed reciprocates to drive the newly entered weft yarn into the woven cloth. In this circular motion, the new weft yarn is continuously driven into the weaving mouth by the reed. And then produce a complete cloth.

[0027] The specific working process of preventing driving marks and parking gears is as follows:

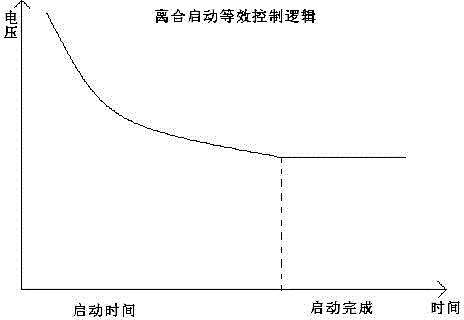

[0028] A very important link in the forming of the cloth is that the reed's reciprocating motion drives the weft yarn newly entering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com