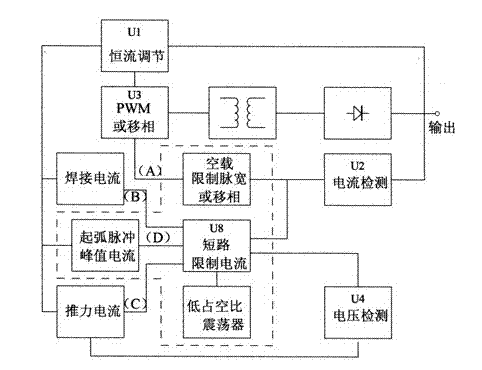

Arc striking pulse peak current control electric welding machine and control method thereof

A technology of peak current control and peak current, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems affecting the safety of power supply equipment, overcurrent impact, welding rod sticking, etc. Effects of overshoot current and inrush current reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

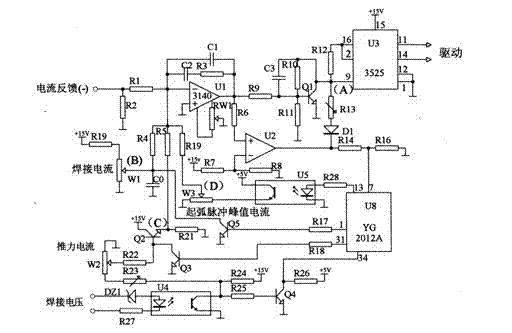

[0037] circuit such as figure 2 As shown, it is a voltage type PWM control circuit type.

[0038] The analysis is as follows: Phase 1: (no load)

[0039] There is no welding current when there is no load, and the given welding current and thrust current are positive values sent to the regulator U1, U1 outputs the minimum value at this time, Q1 is cut off, U3 (3525) is a voltage-type pulse width modulation integrated circuit, the 9th The pin voltage determines the output pulse width, and drives the power switching device to achieve adjustable output power. The 9th foot is the maximum value of the output at this time!

[0040] No signal from the current sampling circuit is sent to U2 to form a current threshold comparison circuit, U2 outputs a low level, R13 will pull down the potential of the 9th pin of U3 (3525) (point A) through D1, and adjust the voltage of R13 and the 9th pin of U3 Clamp the minimum voltage value in the output pulse width. Generally, the no-load outpu...

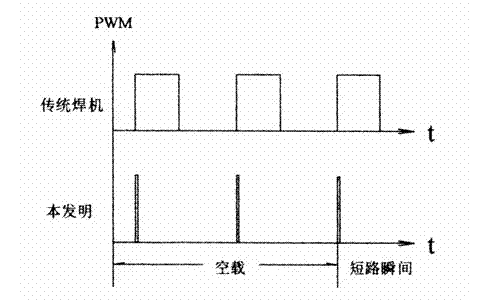

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com