Pile foundation static loading test device

A technology of static load test and pile foundation, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., to achieve the effect of reducing the size of steel beams, simple assembly and disassembly, and fast construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

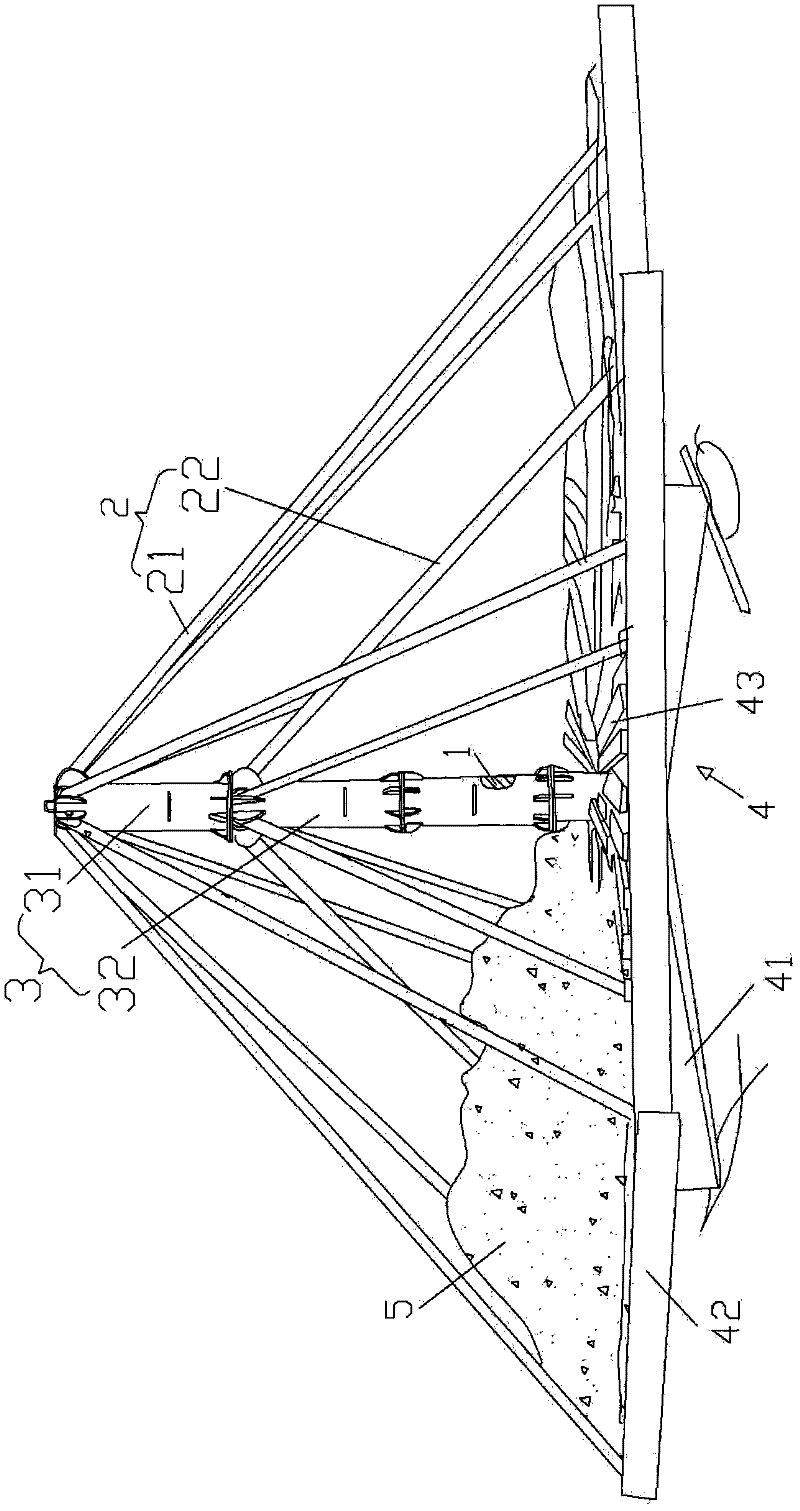

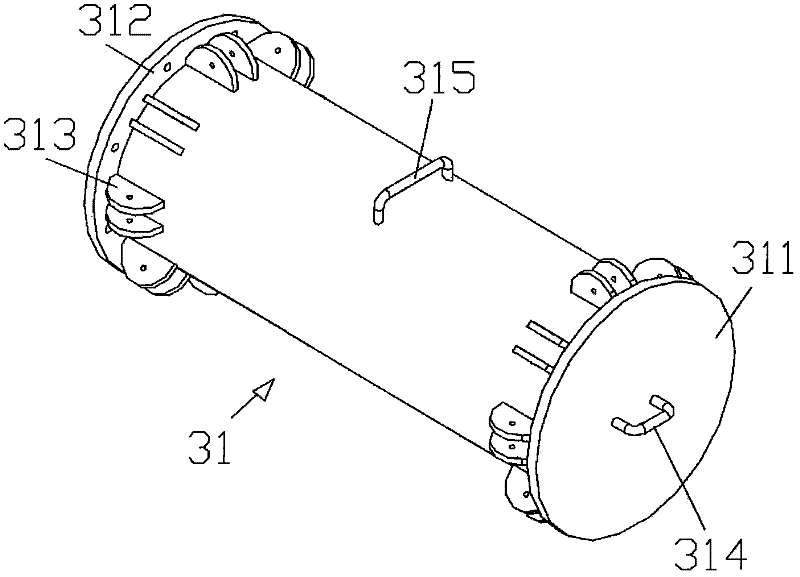

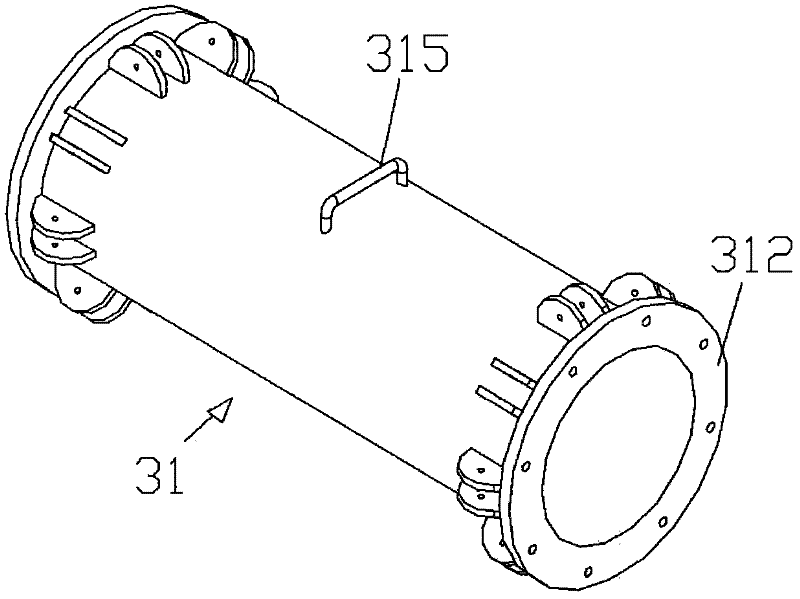

[0024] Example: see Figure 1 to 4 As shown, a pile foundation static load test device includes a pile to be tested 1, a connecting rod 2. The top rod 3 is composed of a foundation section top rod 31 and a connecting section top rod 32, and the foundation section top rod 31 is a top In the cylinder of the cover 311, a base section flange 312 is formed at the lower part of the base section ejector rod 31; the connecting section ejector rod 32 is a hollow cylinder and a connecting section flange 321 is formed at both ends. The base section flange 312 is connected to The joint half plates 321 are fixed together by bolts, the connecting joint flanges 321 of the two connecting joint jacks 32 are fixed together by bolts, the foundation section jack 31 and the connecting section jack 32 are sleeved on the pile 1 to be tested;

[0025] The connecting rod 2 consists of an outer ring connecting rod 21 and an inner ring connecting rod 22. One end of the outer ring connecting rod 21 is hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com