Anti-freezing treatment method for concrete structure foundation in severe cold region

A technology of concrete structure and treatment method, which is applied in basic structural engineering, protection devices, buildings, etc., can solve the problems of using materials, preparation methods without specific regulations and quantitative index requirements, etc., and achieves frost heave thickness. It is easy to guarantee and has a good use effect. , to achieve convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

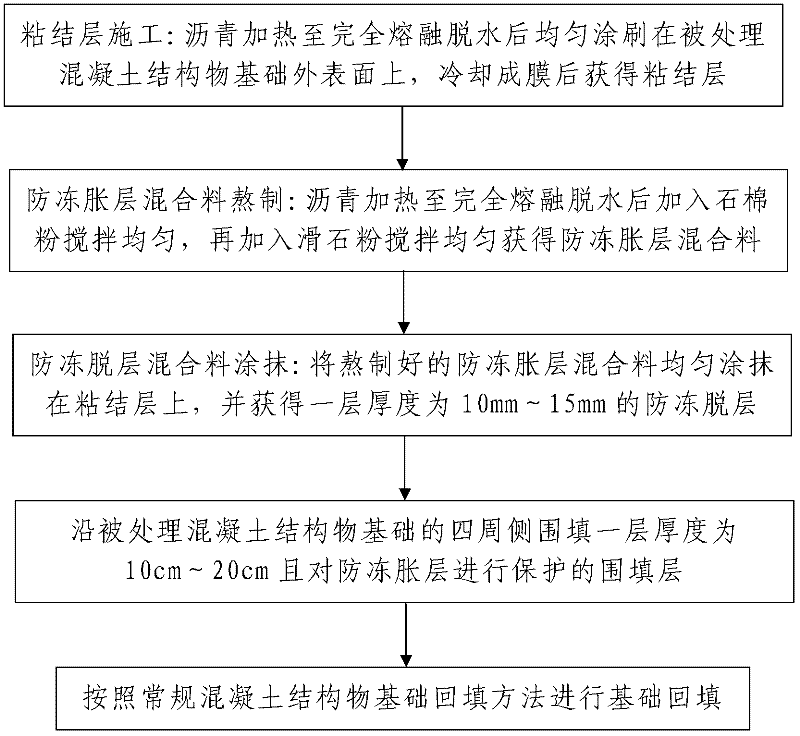

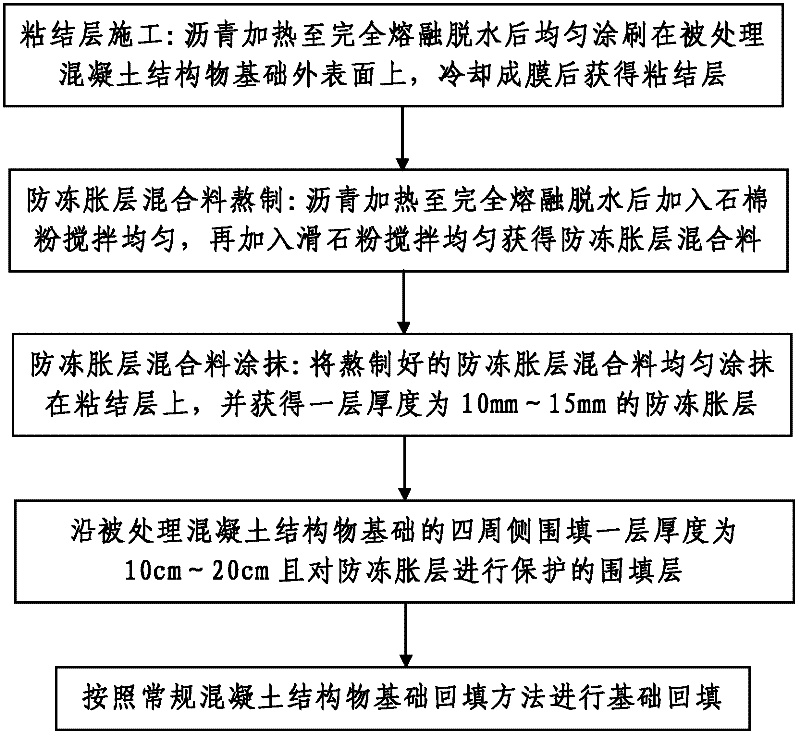

[0030] Such as figure 1 The antifreeze treatment method for the foundation of a concrete structure in a severe cold area includes the following steps:

[0031] Step 1. Bonding layer construction: first heat the asphalt at a temperature of 100°C to 150°C until the heated asphalt is completely melted and dehydrated; after that, apply the melted and dehydrated asphalt to the treated concrete evenly with brushing equipment On the outer surface of the structure foundation, after the asphalt painted on the outer surface of the treated concrete structure foundation is cooled to form a film, a completed bonding layer is obtained.

[0032] The asphalt is an asphalt material with a penetration of 10-15 (0.1mm) at 25°C, a ductility of not less than 1.5cm at 15°C and a softening point of not less than 95°C.

[0033] When actually carrying out the construction of the bonding layer, the asphalt is first heated at a temperature of 130°C to 150°C, and the heated asphalt is completely melted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com