A kind of tunnel cracked secondary lining reinforcement method and device based on sprayed cement-based composite material

A composite material and cement-based technology, which is applied in the direction of tunnel lining, tunnel, shaft equipment, etc., can solve problems such as repeated cracking, and achieve the effects of good deformation ability, excellent working performance and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

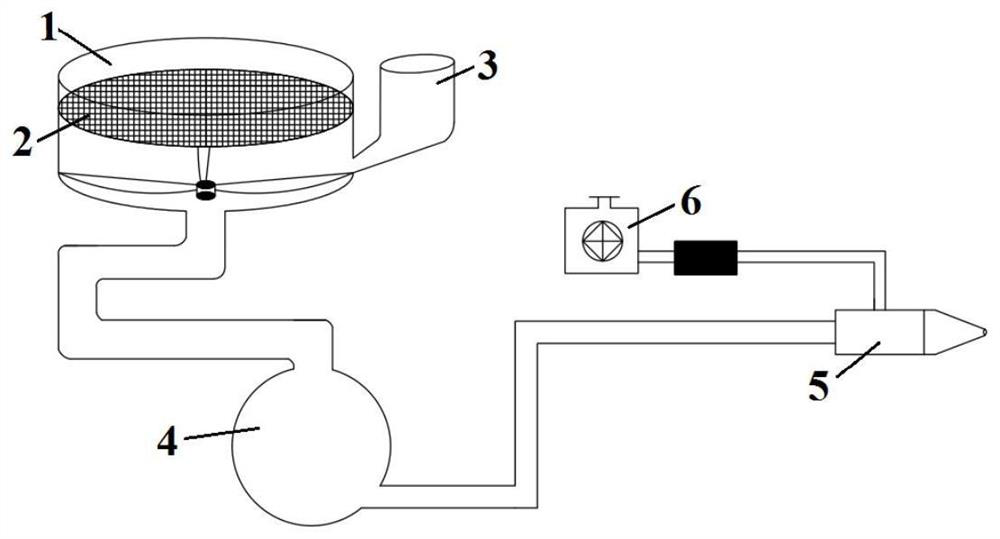

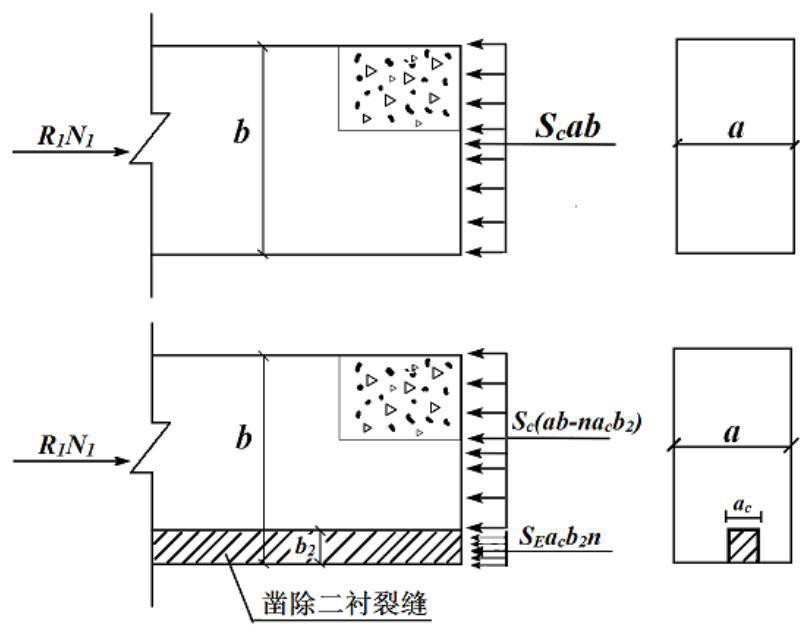

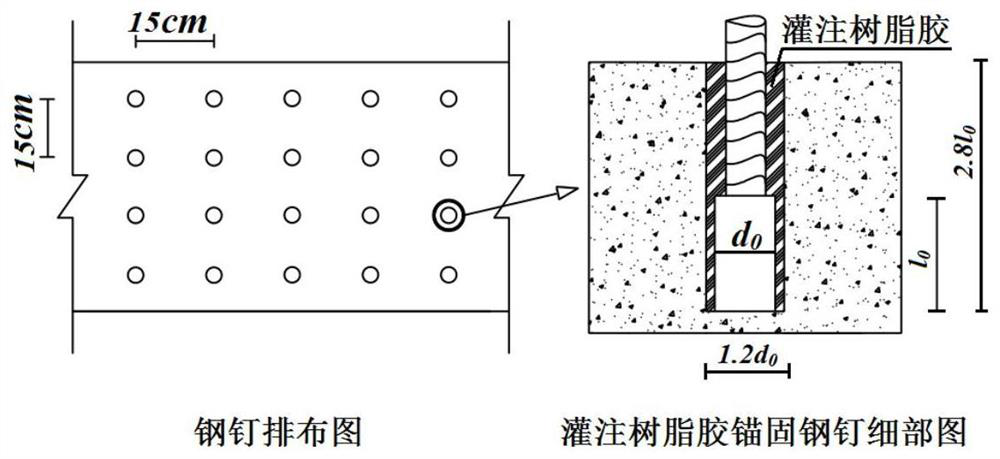

Embodiment 1

[0033] Example 1, as figure 2 As shown: under the action of the surrounding rock compressive stress, the ordinary concrete lining has cracks due to insufficient toughness, ductility and self-shrinkage, or the tunnel lining has repeated cracks. The cement-based composite material of the present invention is used to repair the cracks in the secondary lining of the tunnel. The bearing capacity of the lining is calculated to obtain the minimum thickness of the secondary lining that can be removed along the direction of crack propagation without disturbing the stability and bearing capacity of the original lining structure. 2 , At the same time, it should be ensured that the thickness of the chisel is less than 3.5C, and the debris should be cleaned up in time. At the same time, the surface of the original secondary lining is inclined drilling. Preferably, the drillings are arranged in a grid of 10 × 10 cm, and the depth is 2 cm, and the horizontal direction is 30 °. After the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com