Hook-or-buckle fine assembled combined vertex angle line

A technology of corner lines and corner lines, which is applied in the field of combined top corner lines, buckle fine assembly combined top corner lines, and hooks, which can solve the problems of failing to meet the process requirements, low accuracy of assembly bracket and assembly bracket combination, and assembly matching accuracy Low-level problems, to achieve the effect of precise assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

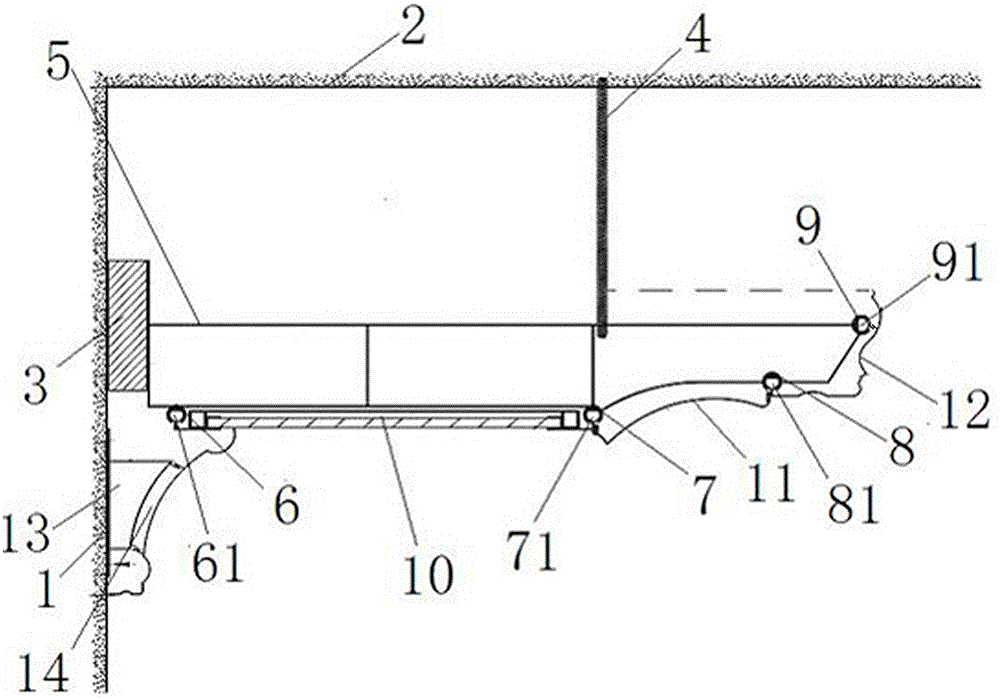

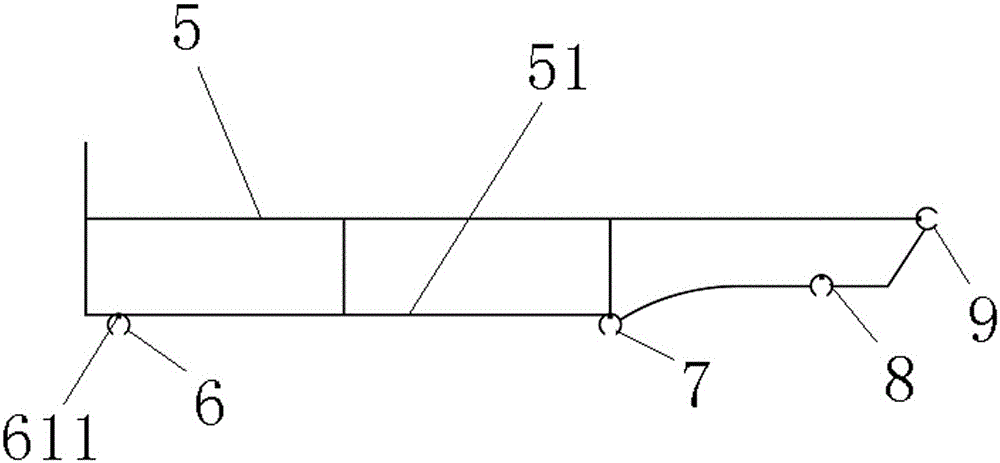

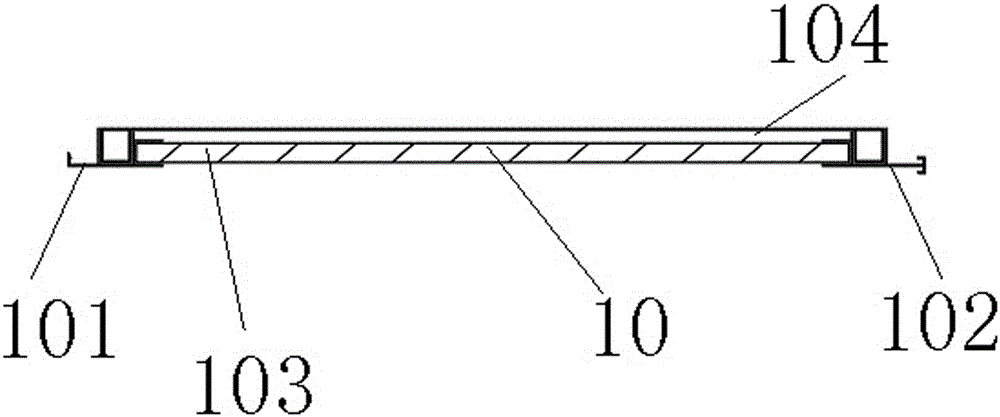

[0023]The present invention will be further explained in detail in conjunction with the accompanying drawings. Each mark in the accompanying drawings is: 1: vertical wall surface; 2: roof surface; 3: vertical adjustment block; 4: horizontal adjustment hanging wire; 5: assembly bracket; 51 : the horizontal plane of the bottom of the total support; 6: open special-shaped assembly tube 1; 61: tubular assembly strip 1 with handle; 611: positioning block; 612: positioning groove; 613: buckle; 7: open special-shaped assembly tube 2; 71: handle Tubular assembly strip two; 713: hook; 8: opening special-shaped assembly pipe three; 81: handle tubular assembly strip three; 9: opening special-shaped assembly pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com