Modern arch type bamboo bridge and construction method thereof

A bamboo and bridge technology, applied in the field of bridge structure, can solve the problems of easy corrosion, poor durability, long construction and maintenance time, etc., achieve stable, reliable and long-term support, strengthen the overall stability, and facilitate the effect of later maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

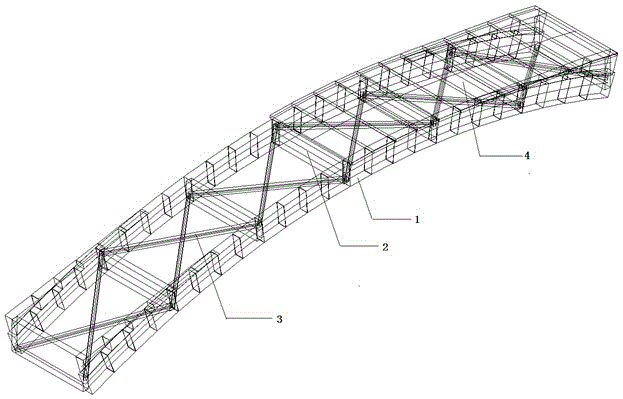

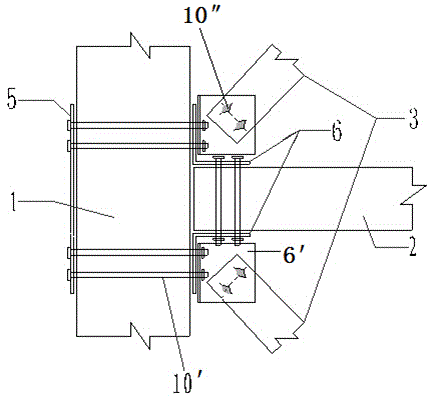

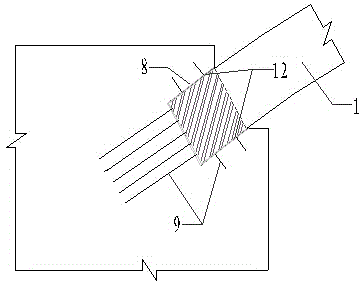

[0045] Such as Figure 1-5 Shown, a modern arched bamboo bridge, including

[0046] Bamboo arch ribs, the bamboo arch ribs 1 are 2 pieces arranged side by side at intervals and are in the shape of a vertical plate as a whole, each bamboo arch rib 1 includes a bamboo arch rib body in the shape of an arc-shaped ring segment as a whole and two overall It is triangular and respectively spliced and arranged on the upper part of the two ends of the bamboo arch rib main body, so that the middle part of the upper surface of the bamboo arch rib 1 is an arc surface and the two ends are inclined planes. The main body of the bamboo arch rib and the guard arch are respectively All of them are composed of multiple bamboo boards of recombined bamboo material connected by channel steel and bolts. Between each two adjacent bamboo boards, a pair of channel steel 7 wraps the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com