A foundation ring and its processing and construction method

A foundation ring and foundation technology, which is applied in the field of wind power installations, can solve problems such as the limited number of perforated steel bars, loose and damaged concrete around the perforated steel bars, and difficult operation of bar piercing, so as to avoid damage to the ring structure by opening holes and reduce shear damage risk, and the effect of solving the difficulty of threading operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the present invention will be further introduced by describing preferred specific embodiments in detail in conjunction with the accompanying drawings.

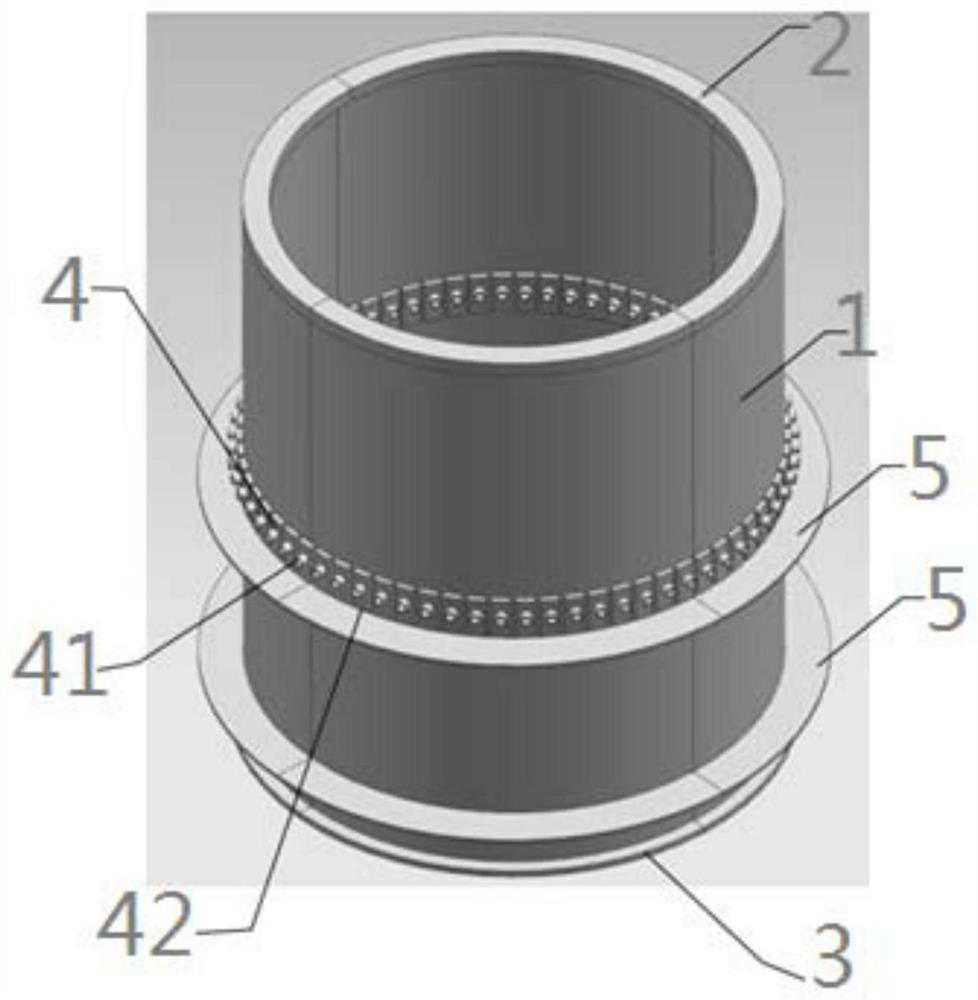

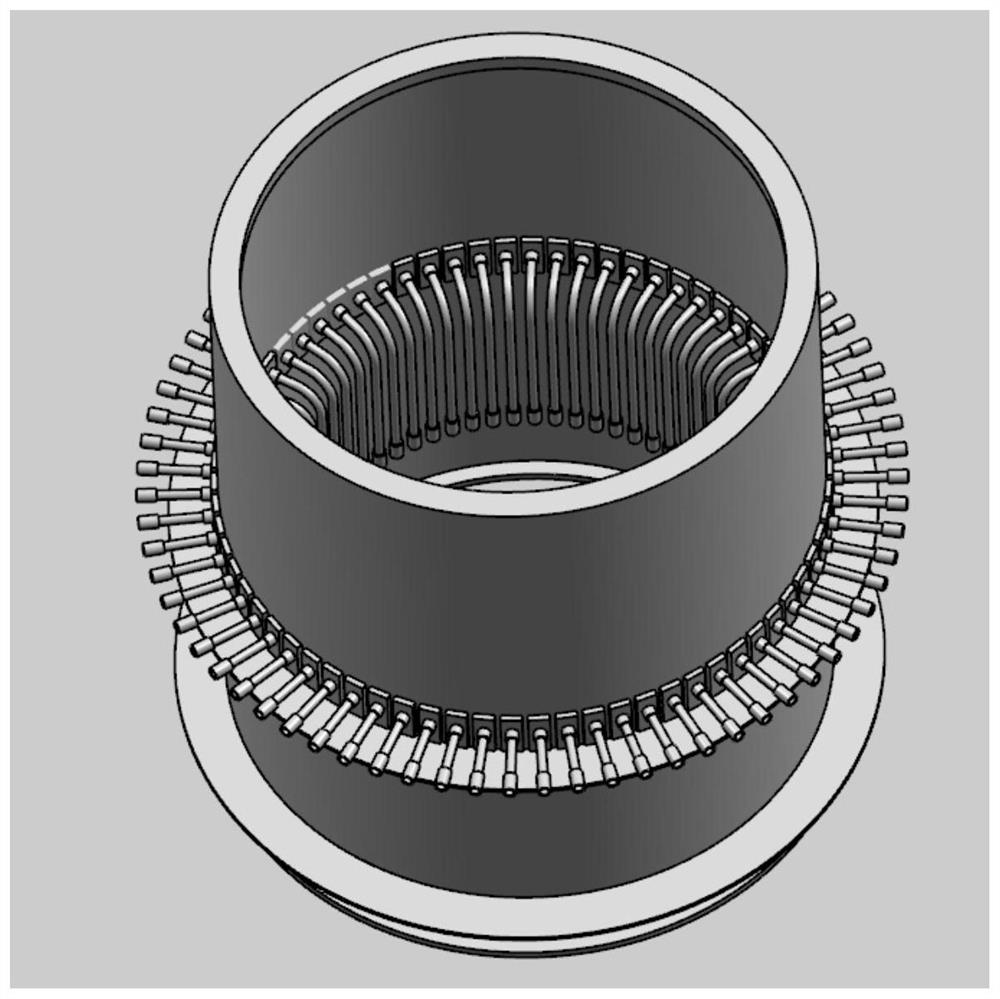

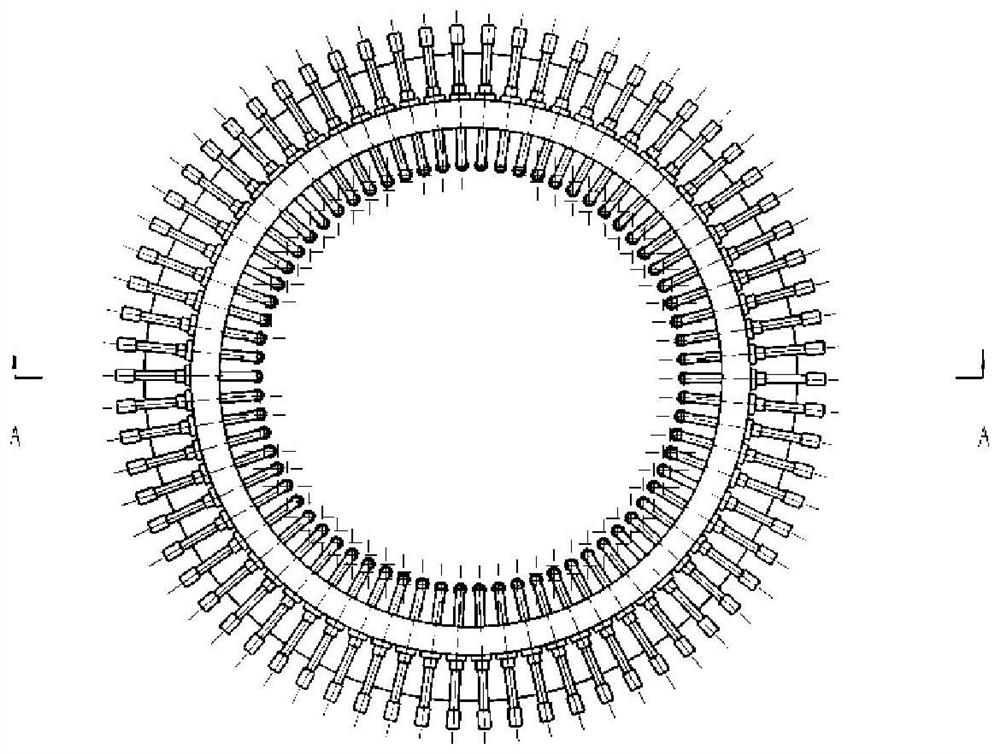

[0035] The invention provides a foundation ring for connecting the tower and the foundation, figure 1 It is a structural schematic diagram of the basic ring of the present invention. Such as figure 1 As shown, the basic ring provided by the present invention includes a ring body 1 , a top flange 2 , a bottom flange 3 and several steel connectors 4 .

[0036] The ring body 1 is a hollow cylindrical structure formed by welding one or more rectangular steel plates. The upper end of the ring body 1 is welded and fixed with the top flange 2, and the top flange 2 is used for connecting with the flange at the bottom of the tower. Specifically, during the construction of the foundation ring, fasteners such as bolts are used to pass through the through holes of the top flange 2 and the tower flange to clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com