Pipeline repair method and repaired pipeline

A pipeline repair and pipeline technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of pipeline structural damage, complicated operation, etc., and achieve the effect of fast construction operation and good leakage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below with a specific embodiment in conjunction with the accompanying drawings.

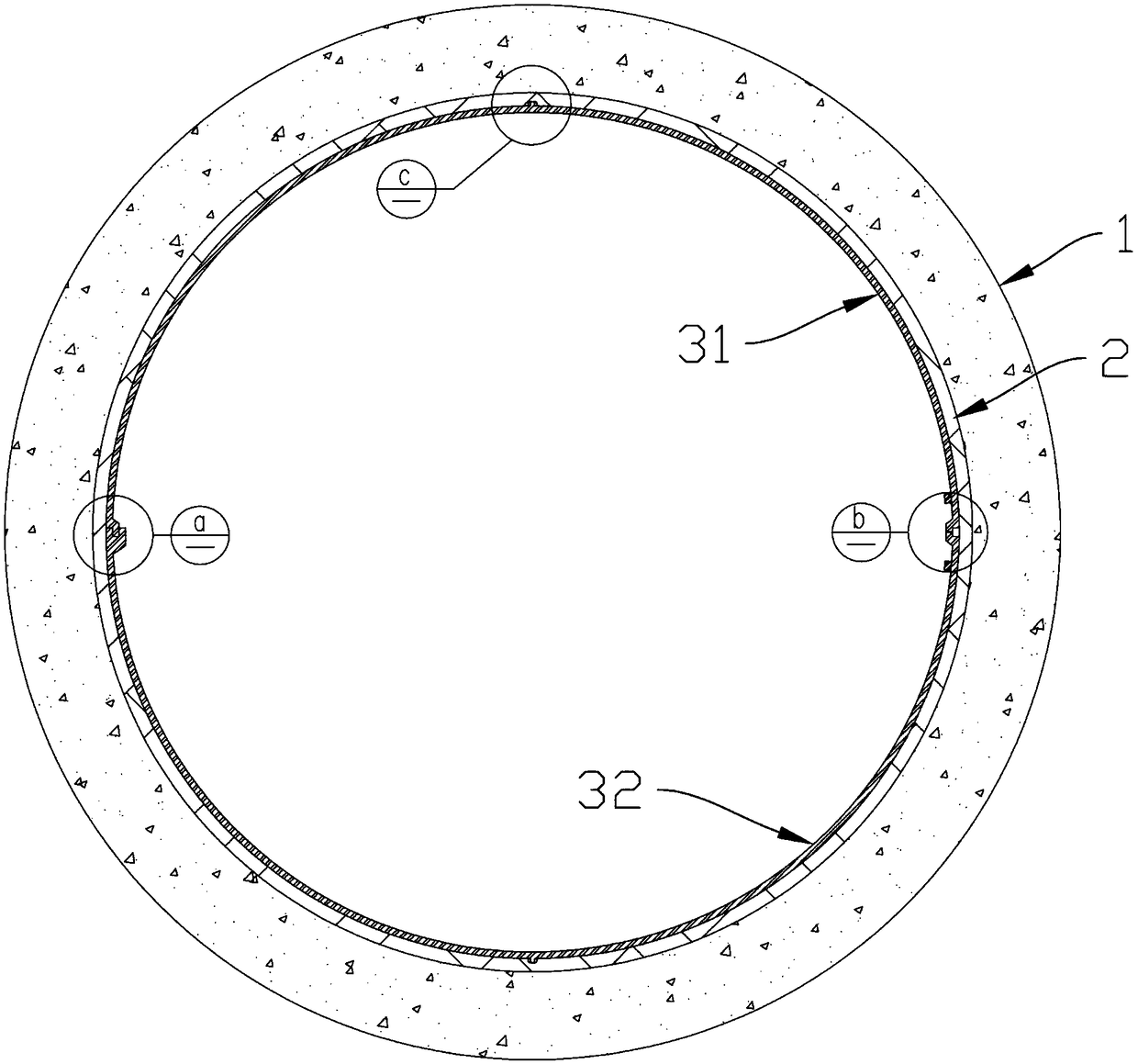

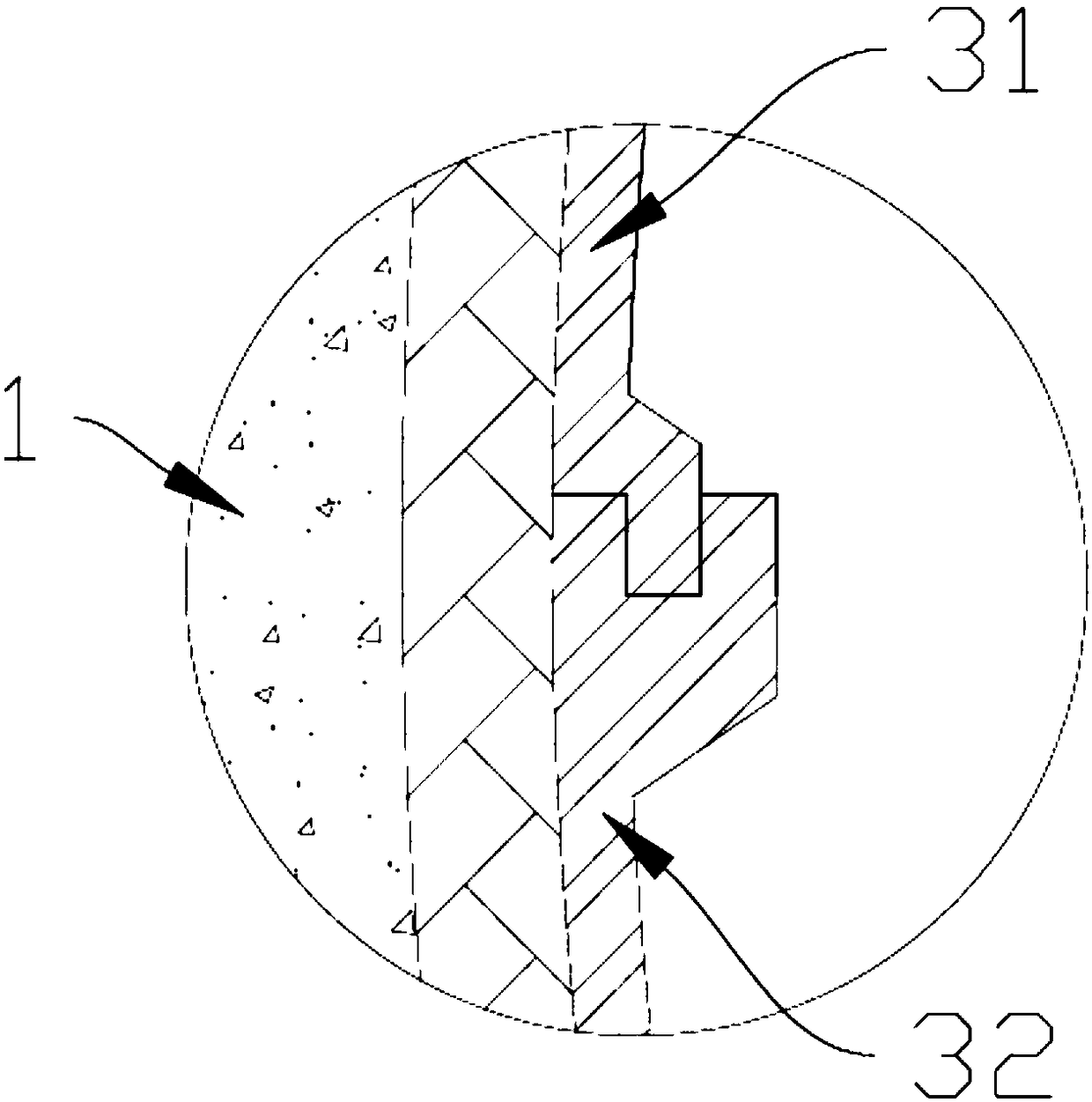

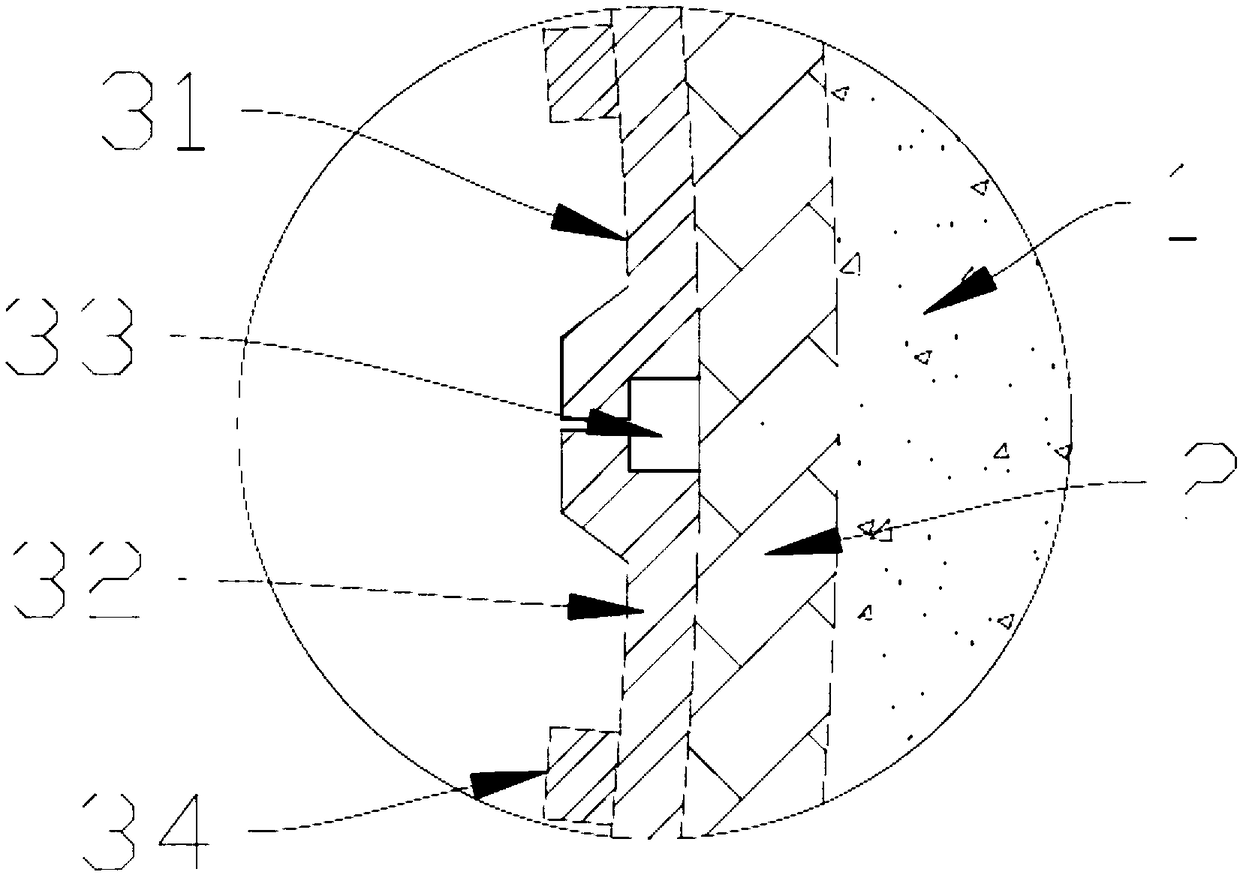

[0043] Such as figure 1 As shown, a repaired pipeline includes a pipeline body 1 , a sealant layer 4 , a rubber seal layer 2 and a rigid annular adjustment assembly.

[0044] The pipeline body 1 is the pipeline to be repaired, that is, it contains pipeline dislocations, or / and pipeline gaps. The dislocations are mainly caused by uneven settlement between pipe joints at the pipeline interface due to geological differences. Pipeline gaps mainly refer to the adjacent pipe joints at the pipeline interface. gaps and gaps formed by cracks in the inner wall of the pipe. Such as Figure 6 The working condition in which there is a gap between adjacent pipe joints at the pipe joint is shown, and this working condition is used for description in this embodiment. Sealant is filled in the pipe gap to form a sealant layer 4 . In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com