Wall installing method for blast furnace casting house plant

A technology of blast furnace tapping and installation method, which is applied to walls, building components, buildings, etc., can solve the problems of increased safety risks in high-altitude installation operations, unfavorable control of installation accuracy, and difficulty in ensuring welding quality, and saves labor costs. , The effect of improving construction quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

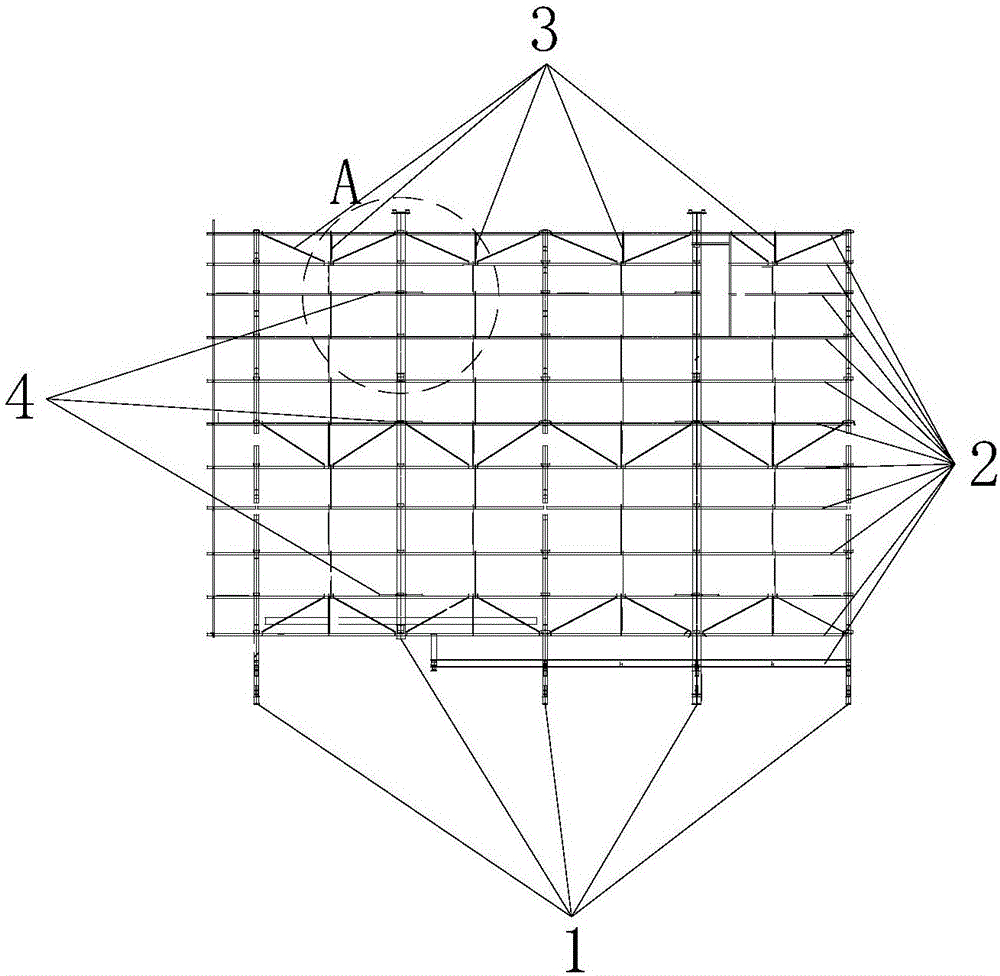

[0025] Such as figure 1 As shown, the method for installing the walls of blast furnace casthouse factory buildings of the present invention comprises the following steps:

[0026] 1) According to the installation design size of the wall skin, determine a sufficiently spacious assembly site;

[0027] 2) First place the wall pillars at the corresponding positions of the assembly site, and uniformly adjust the elevation of the wall pillars to ensure that the wall pillars are on the same level;

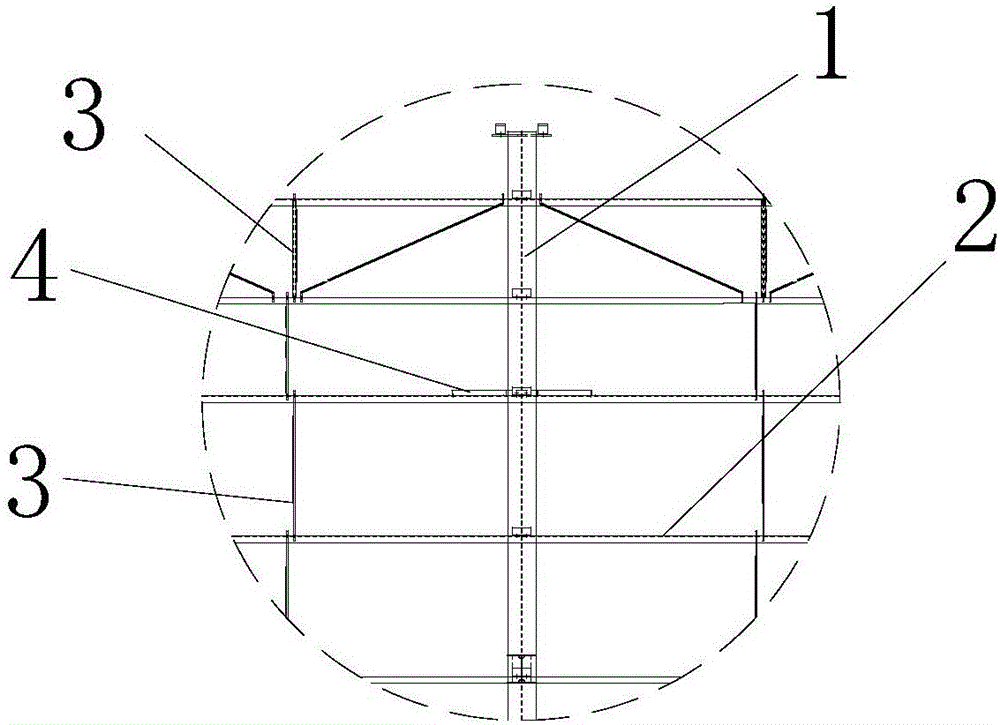

[0028] 3) Install wall skin purlins 2, wall skin braces 3, and purlin corner braces 4 in sequence;

[0029] 4) After the wall skin columns 1, wall skin purlins 2, wall skin braces 3, and purlin corner braces 4 are installed, uniformly adjust the wall skin levelness and wall skin purlin 2 straightness to ensure that the requirements of the drawings and specificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com