Construction joints and construction methods of concrete structures with large height difference and variable cross-section

A concrete structure with variable cross-section technology, which is applied in water conservancy projects, sea area projects, building structures, etc. It can solve the problems of high construction risk, difficulty in formwork reinforcement, and large concrete thickness, etc., and achieves convenient construction operations and simple laying methods , The effect of speeding up the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

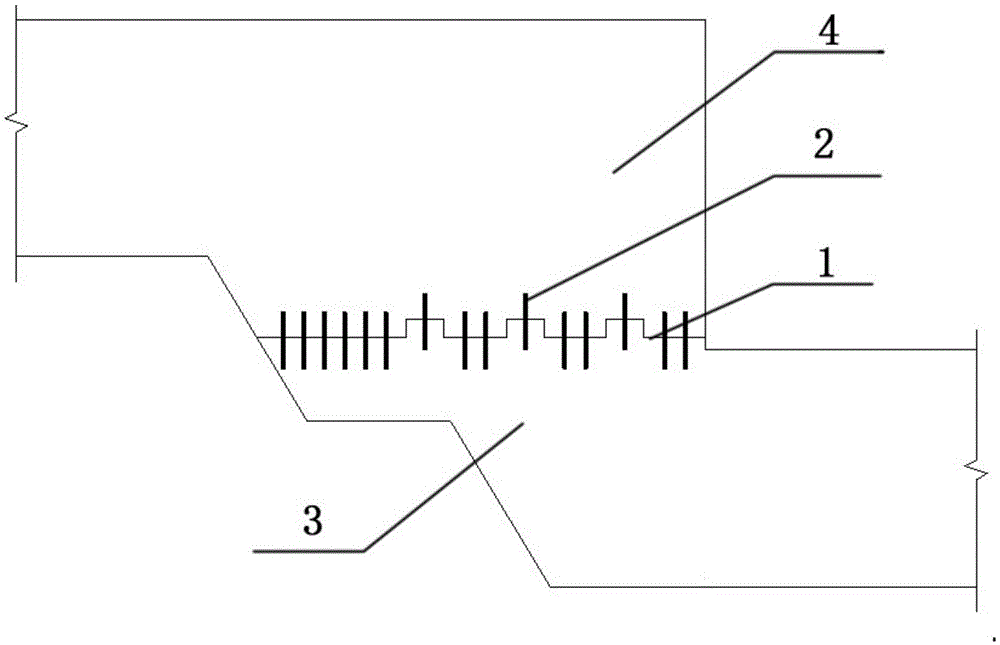

[0022] Such as figure 1 As shown, the construction joint of the concrete structure with large height difference and variable cross-section of the present invention is composed of the lower structure 3, the upper structure 4, the construction joint 1 between the upper and lower structures and the vertical reinforcement 2 between the horse teeth.

[0023] The upper structure 4 and the lower structure 3 are respectively provided with a horse-toothed bar 1 and a vertically inserted bar 2 is buried between the upper structure 4 and the lower structure 3, and the vertically inserted bar 2 is preferably a HRB335 steel bar with a diameter of 12mm. , the vertical steel bars 2 are used to make the connection between the upper structure 4 and the lower structure 3 more firm, and the upper structure 4 and the lower structure 3 formed correspondingly. It is convenient to connect the 4 horse-toothed chasms in the upper structure and the 3 horse-toothed chasms in the lower structure.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com