A lap joint self-centering friction energy dissipation support

A friction energy-consuming and self-centering technology, applied in building components, earthquake-proof and other directions, can solve the problems of sudden change in stiffness and self-weight, and achieve the effect of reducing weight, reducing the self-weight of supports, and reducing the maximum floor acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

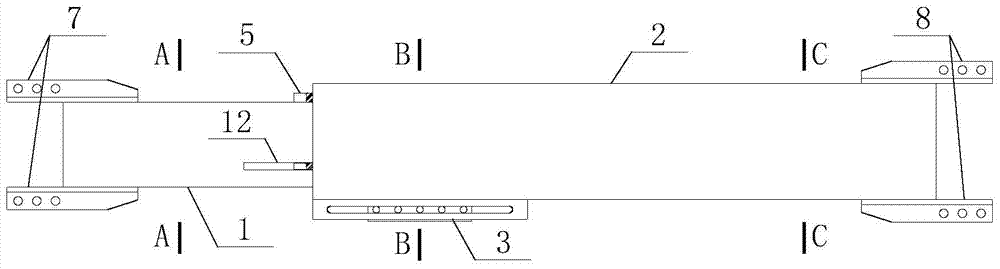

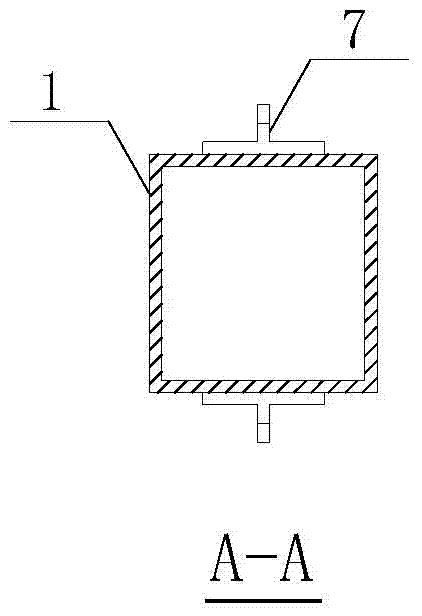

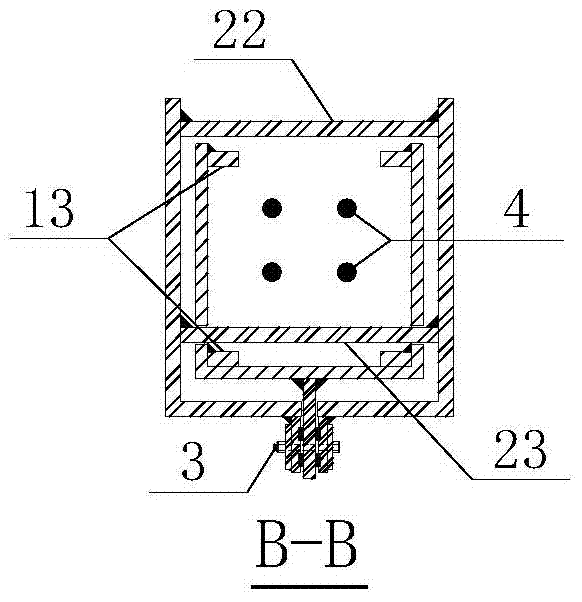

[0045] Such as Figure 1 to Figure 5 As shown, the overlapping self-centering friction energy dissipation support of the present invention includes a rectangular inner sleeve 1, a rectangular outer sleeve 2, a frictional energy dissipation component 3 connecting the bottom plate of the inner sleeve 1 and the bottom plate of the outer sleeve 2, and is arranged in the inner The first end plate 5 in the sleeve 1, the second end plate 6 arranged in the outer sleeve 2, the pre-sets arranged in the inner sleeve 1 and anchored to the first end plate 5 and the second end plate 6 at both ends respectively Pull rod 4, a part of the inner sleeve 1 is inserted into the outer sleeve 2 and overlapped with it, one end of the inner sleeve 1 inserted into the outer sleeve 2 is in contact with the second end plate 6, and the first end plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com