A spiral cable support

A spiral and seat plate technology, which is applied in bridge materials, buildings, bridge construction, etc., can solve the problems of complex structure and heavy weight of the upper seat plate and the lower seat plate, and achieve the advantages of small space occupation, weight reduction and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

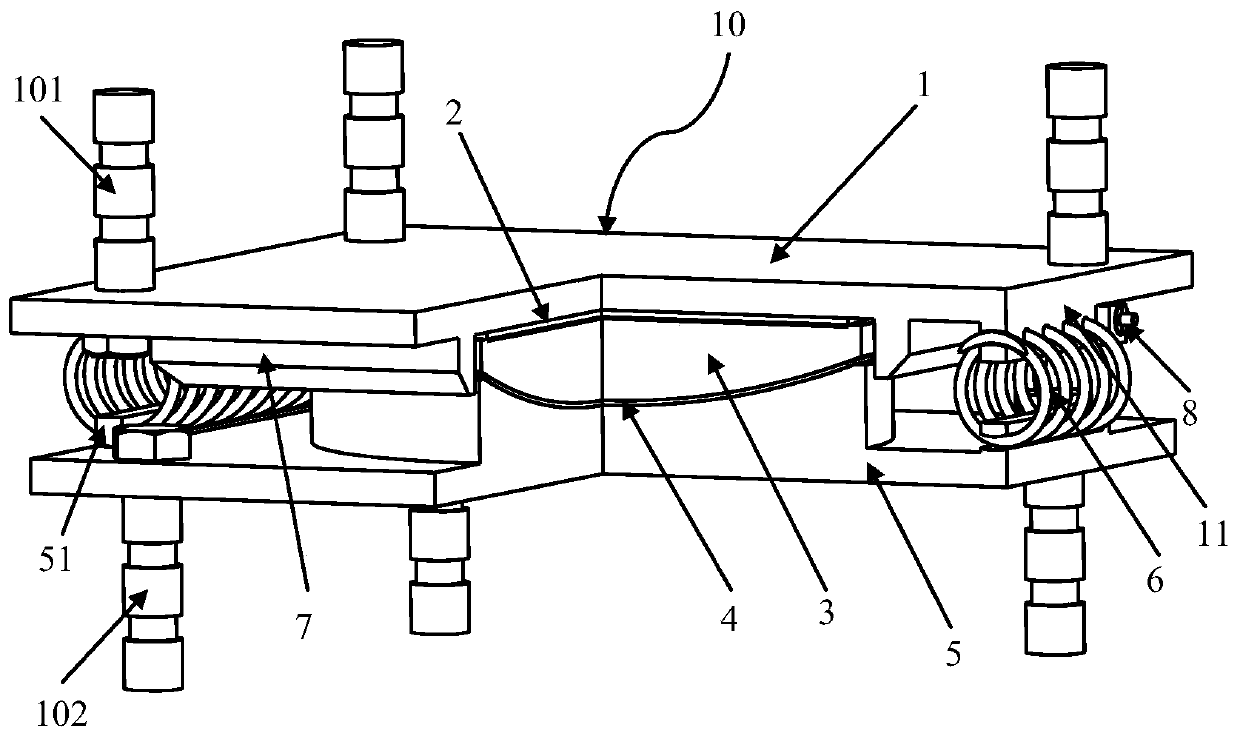

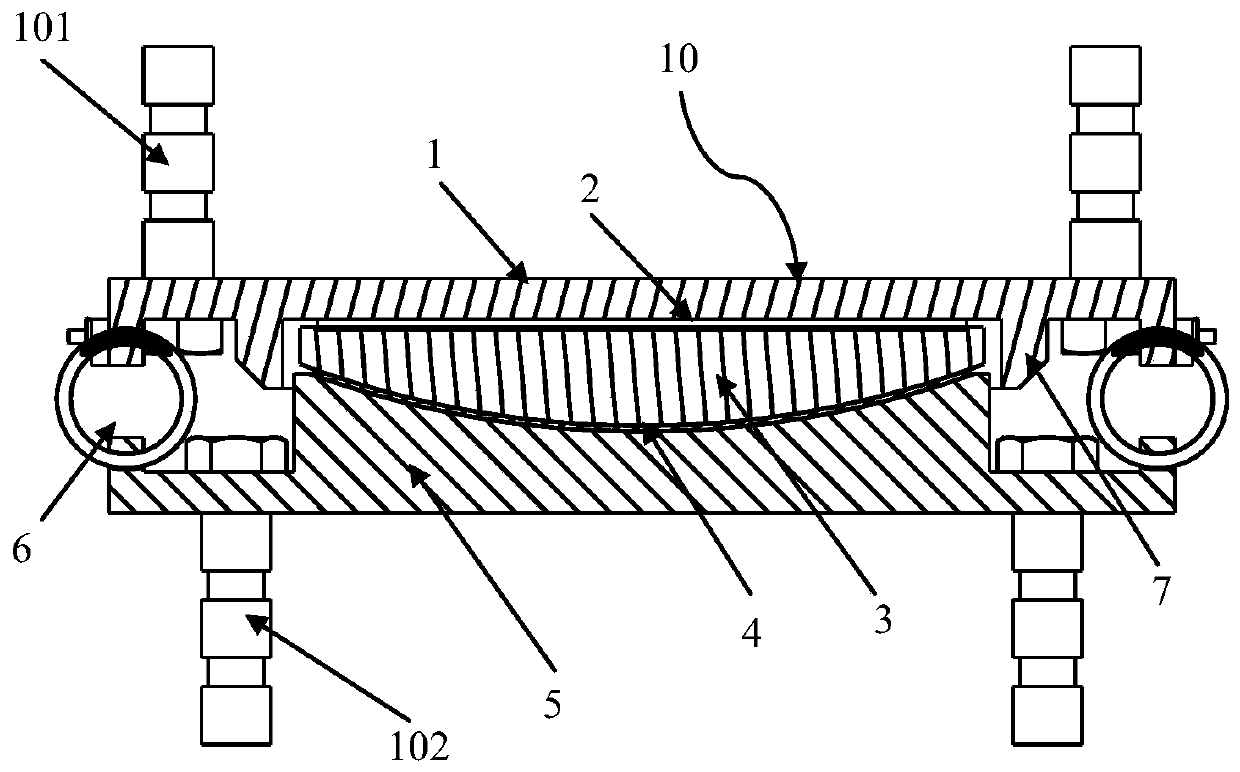

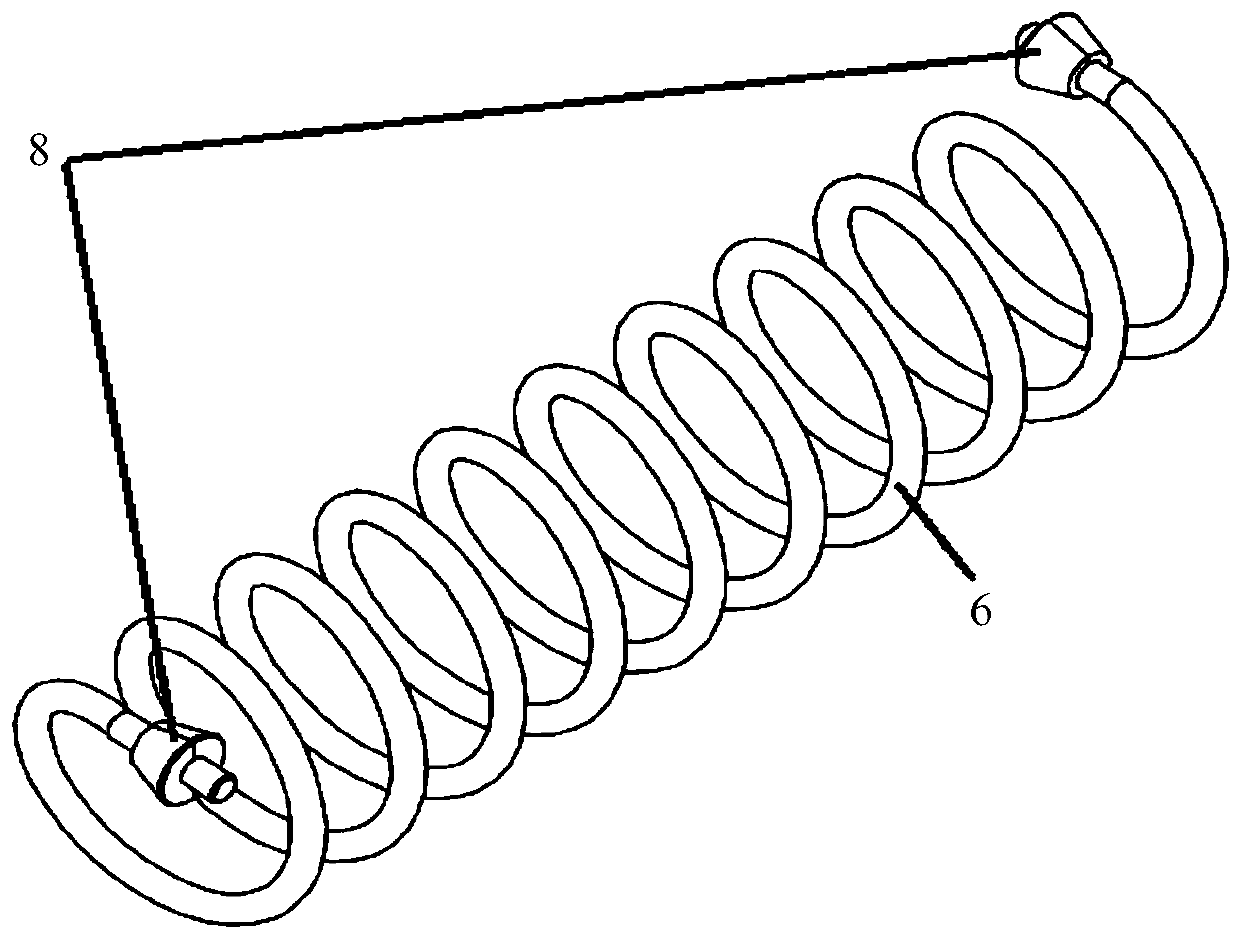

[0031] Such as figure 1 with figure 2 As shown, the spiral cable support 10 of the embodiment of the present invention includes an upper seat plate 1 , an upper slide plate 2 , a spherical crown lining plate 3 , a lower spherical slide plate 4 , a lower seat plate 5 and a spiral cable 6 . The upper slide plate 2 is configured as a plane slide plate arranged between the upper seat plate 1 and the spherical cap liner 3 , and the upper surface and the lower surface of the upper slide plate 2 cooperate with the bottom of the upper seat plate 1 and the top of the spherical crown liner 3 respectively. The lower spherical sliding plate 4 is arranged between the spherical cap liner 3 and the lower seat plate 5 , and the upper surface and the lower surface of the lower spherical sliding plate 4 cooperate with the bottom of the spherical cap liner 3 and the top of the lower seat plate 5 respectively. The spiral stay cables 6 are connected to the upper seat plate 1 and the lower seat p...

Embodiment 2

[0037] Such as Image 6 As shown, the spiral cable support 20 of the embodiment of the present invention includes an upper seat plate 1, an upper slide plate 2′, a spherical crown lining plate 3, a lower spherical slide plate 4, a lower seat plate 5 and a spiral stay cable 6. The upper slide plate 2' is configured as a spherical slide plate arranged between the upper seat plate 1 and the spherical crown lining plate 3, and the upper surface and the lower surface of the upper sliding plate 2 are respectively matched with the bottom of the upper seat plate 1 and the top of the spherical crown lining plate 3. The lower spherical sliding plate 4 is arranged between the spherical cap liner 3 and the lower seat plate 5 , and the upper surface and the lower surface of the lower spherical sliding plate 4 cooperate with the bottom of the spherical cap liner 3 and the top of the lower seat plate 5 respectively. The spiral stay cables 6 are connected to the upper seat plate 1 and the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com