Denitration high-temperature flue pull rod fixing structure

A high-temperature flue and fixed structure technology, applied in the field of flue gas denitrification, can solve problems such as increased investment, increased structural load, and increased engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

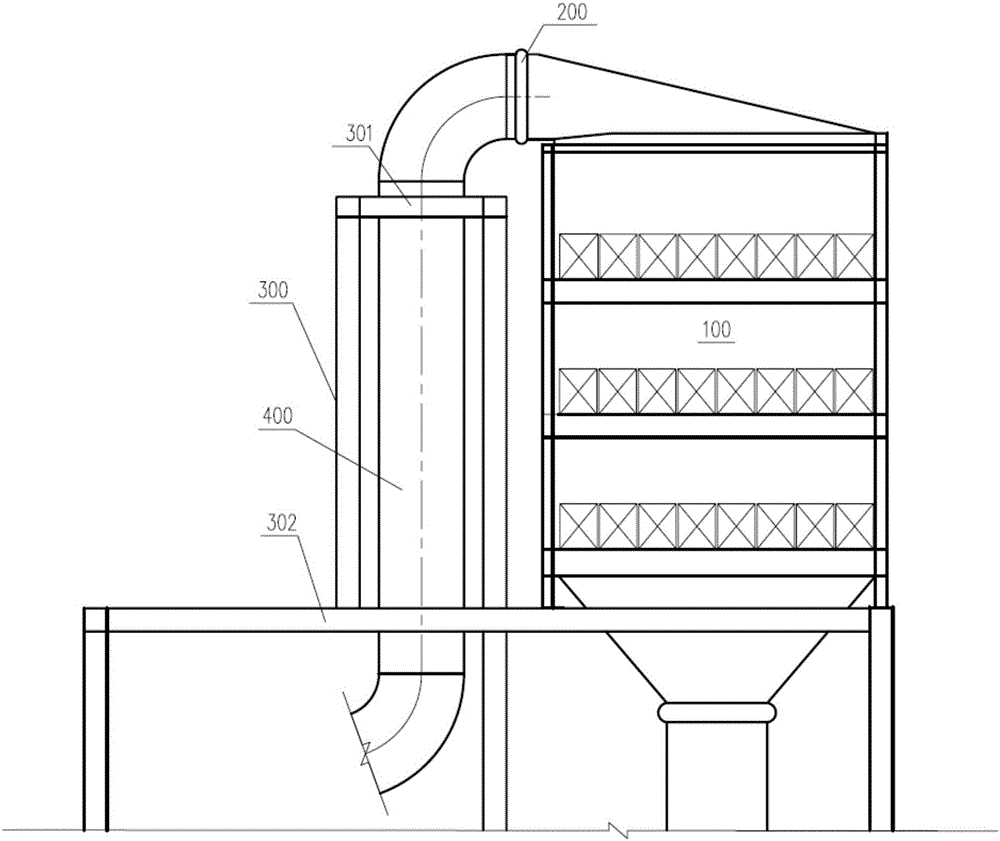

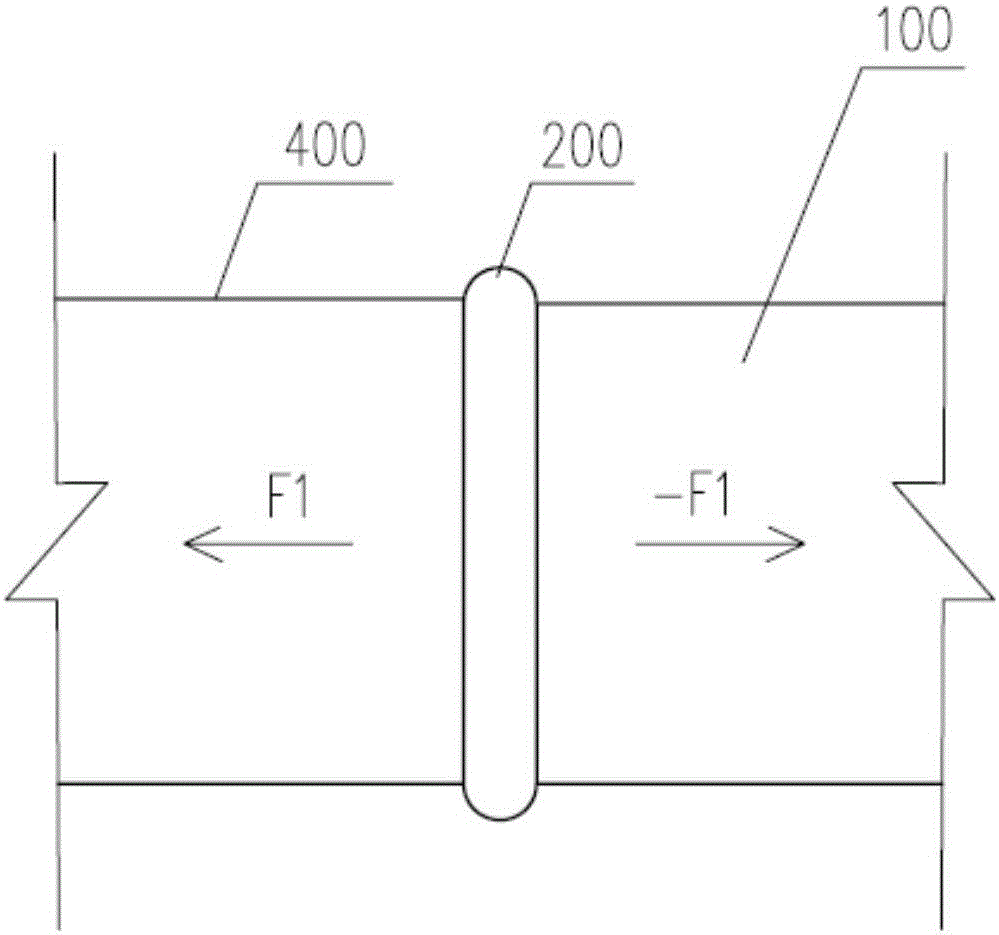

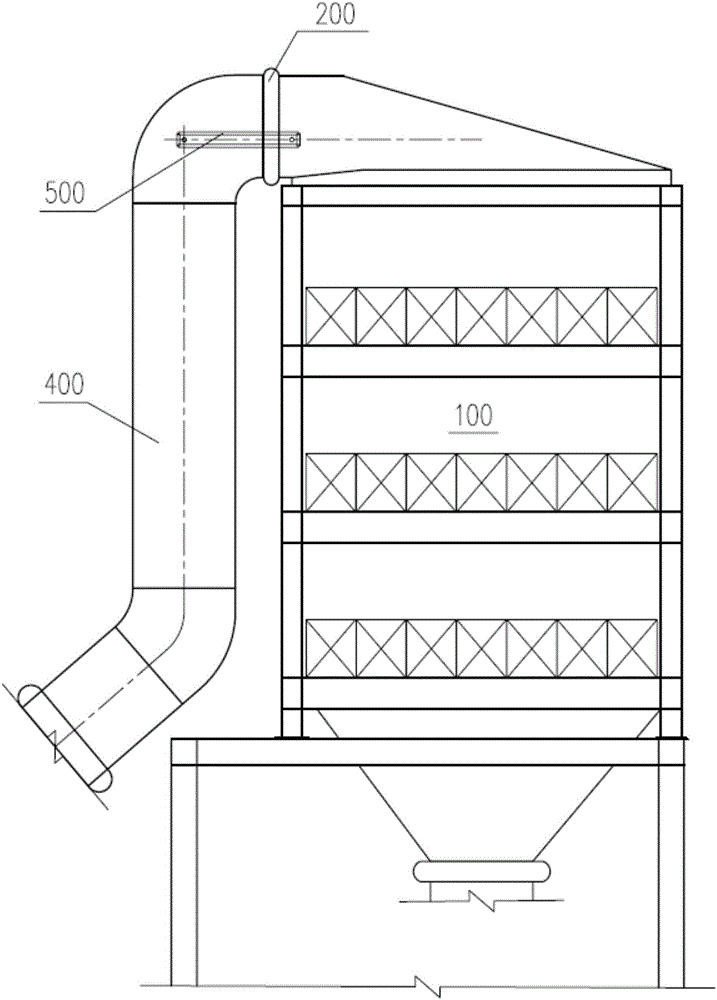

[0041] Such as image 3 As shown, in one embodiment, a fixing structure for the denitrification high-temperature flue tie rod is described, which is arranged outside the non-metallic expansion joint 200 connecting the denitrification reactor 100 and the inlet flue 400. As shown in the figure, the inlet flue 400 includes A vertical flue at the bottom and a horizontal flue at the top, combined with Figure 4 and Figure 5 , the structure includes:

[0042] Two sets of tie rod assemblies 500 are symmetrically arranged on both sides of the denitrification reactor 100 and the inlet flue 400. One set of tie rod assemblies 500 includes: two tie rod fixing parts 502 fixed on the outside of the denitrification reactor 100 and the outside of the inlet flue. The ends are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com